|

Attention! The product has been discontinued. Check other products incategory. |

Attention!In order to purchase a printer, please contact us by e-mail: biuro@botland.com.pl. The final price of the printer depends on the selected configuration. |

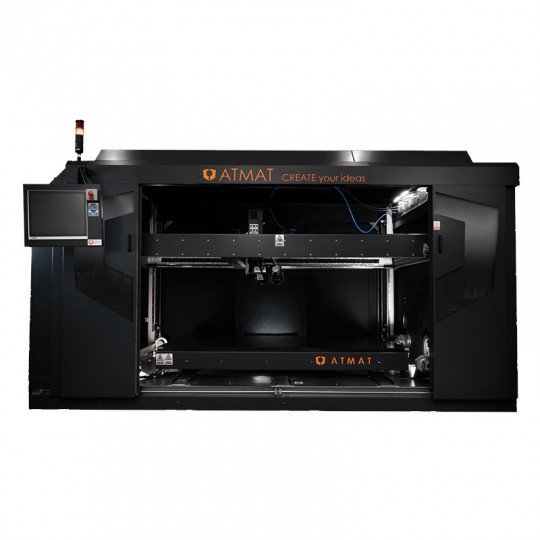

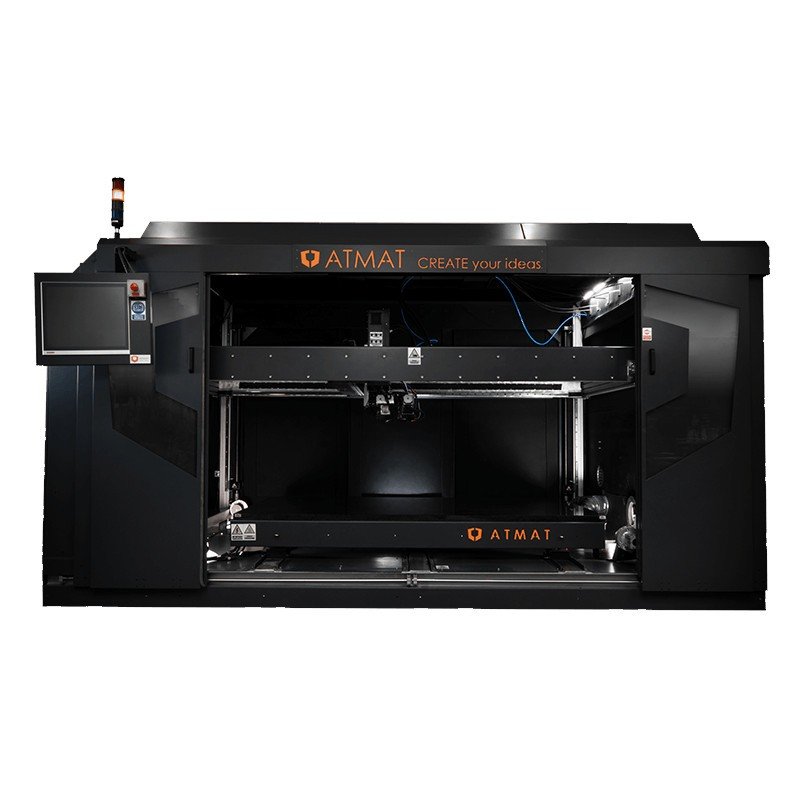

Product description: 3D printer - ATMAT Jupiter

3D printer bythe Polish company ATMAT, designed forindustrial printing oflarge-size models with dimensions of1200 x 1000 x 1000 mm. ATMATSaturnhas been closed ina sealed working chamber. The printer hastwo heads and three extruders, enabling printingin different colours or materials. The touch panel makes it much easier to operate the device interface.

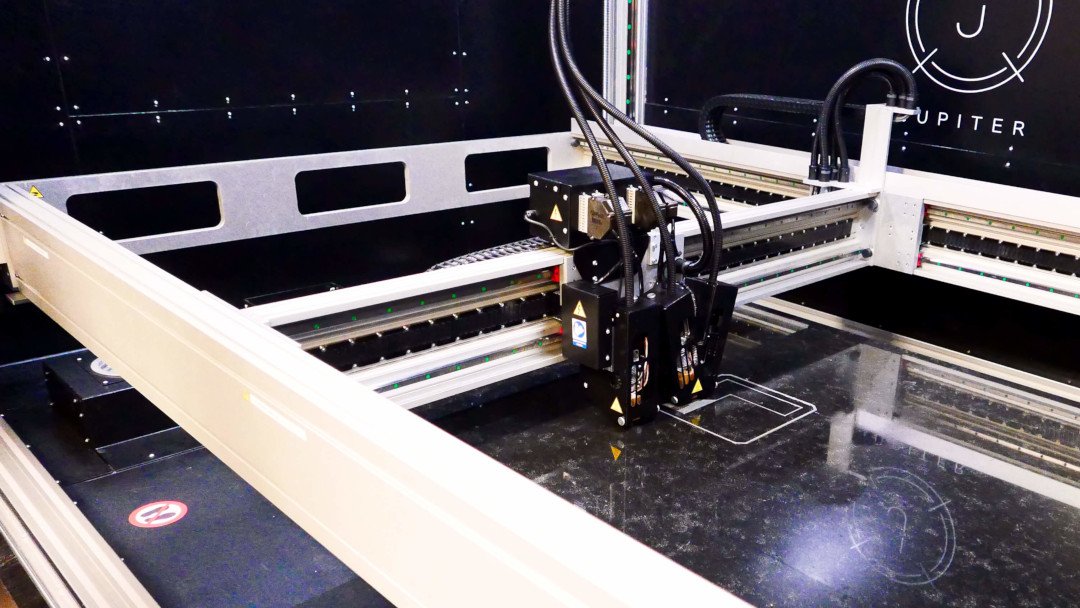

ATMAT Jupiter 3D printer

The application ofthe DIRECT type extruderin ATMAT Jupiter allows to print from a wide range offilamentsfromPLA,PET,ABSto flexible materials, rubber or plastics with admixtures of wood, metals or mineral additives.

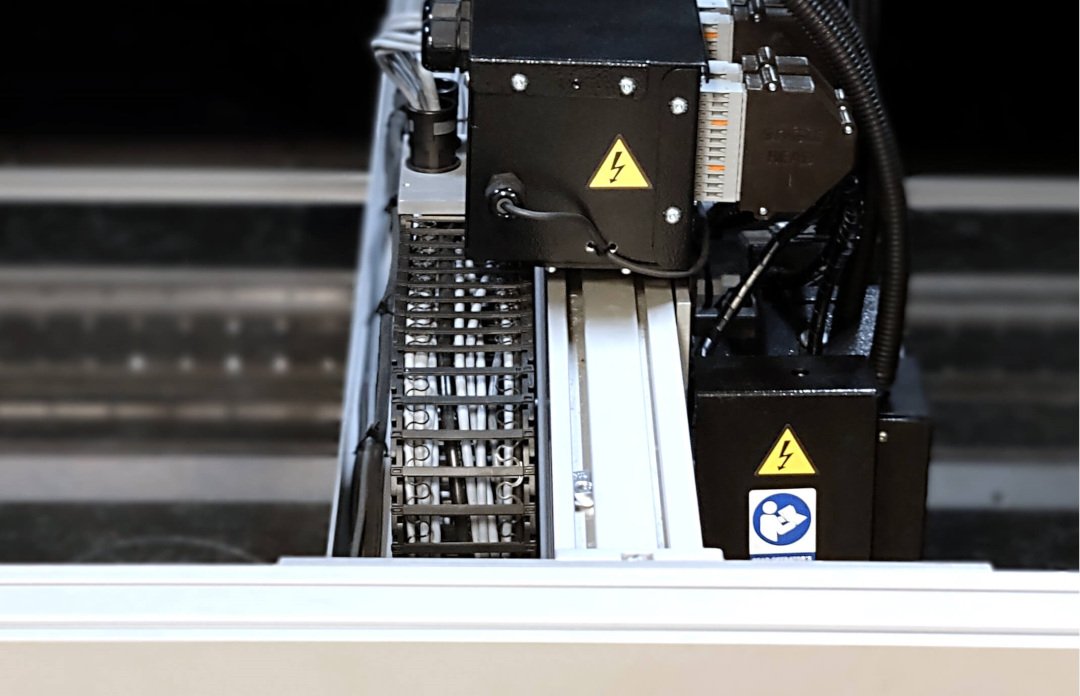

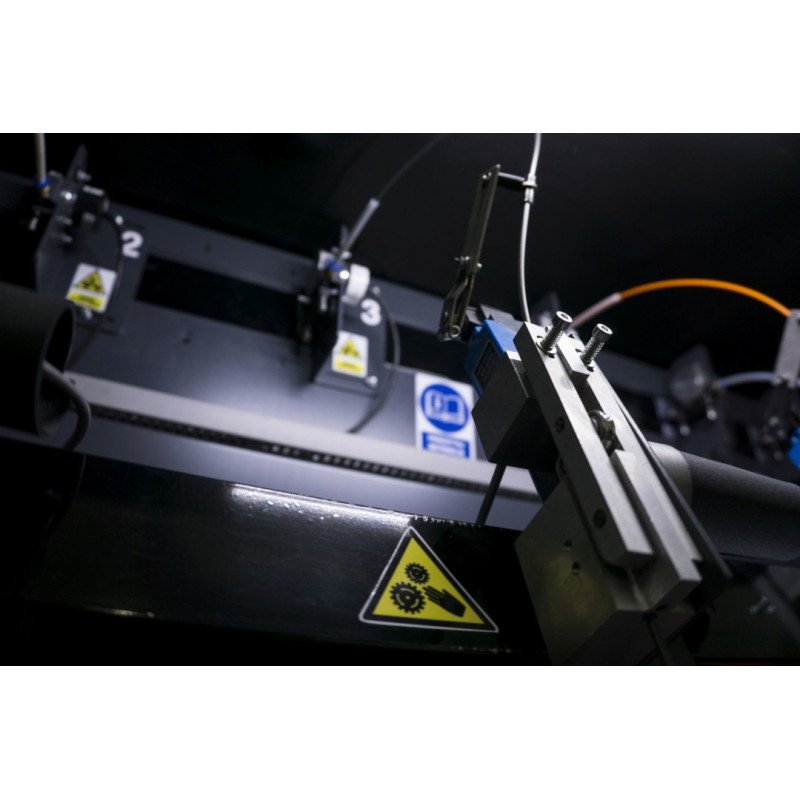

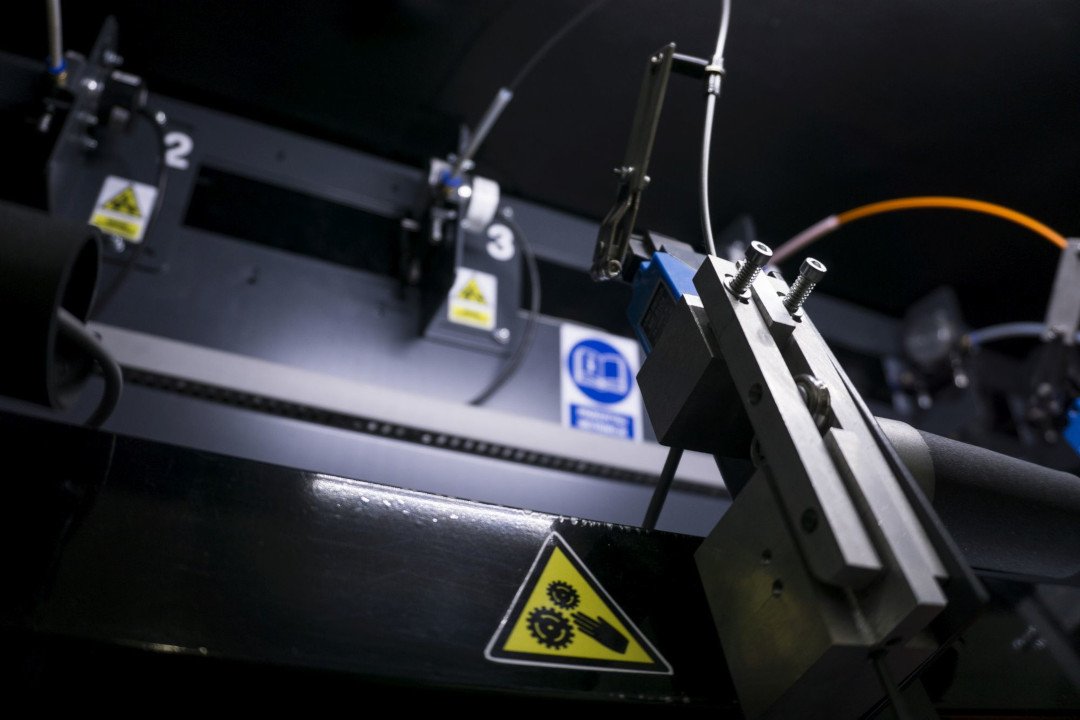

Multi-port head

A high-performancedouble headwith support, which enables the printer to perform its primary function of uninterrupted operation, resulting in high quality prints. The head has two extruders with a connected fialement tank. It allowed to achieve excellent results of the device's working time, and at the same time did not deteriorate the quality of the printed surface. Smooth material flow guarantees uninterrupted operation, which is the basic requirement for 3D printers. As a result, it translates into high productivity with simultaneous acceleration and improvement of the production process. A second auxiliary head with a single extruder allows to create supports or models with higher accuracy.

Highly efficient printing system.

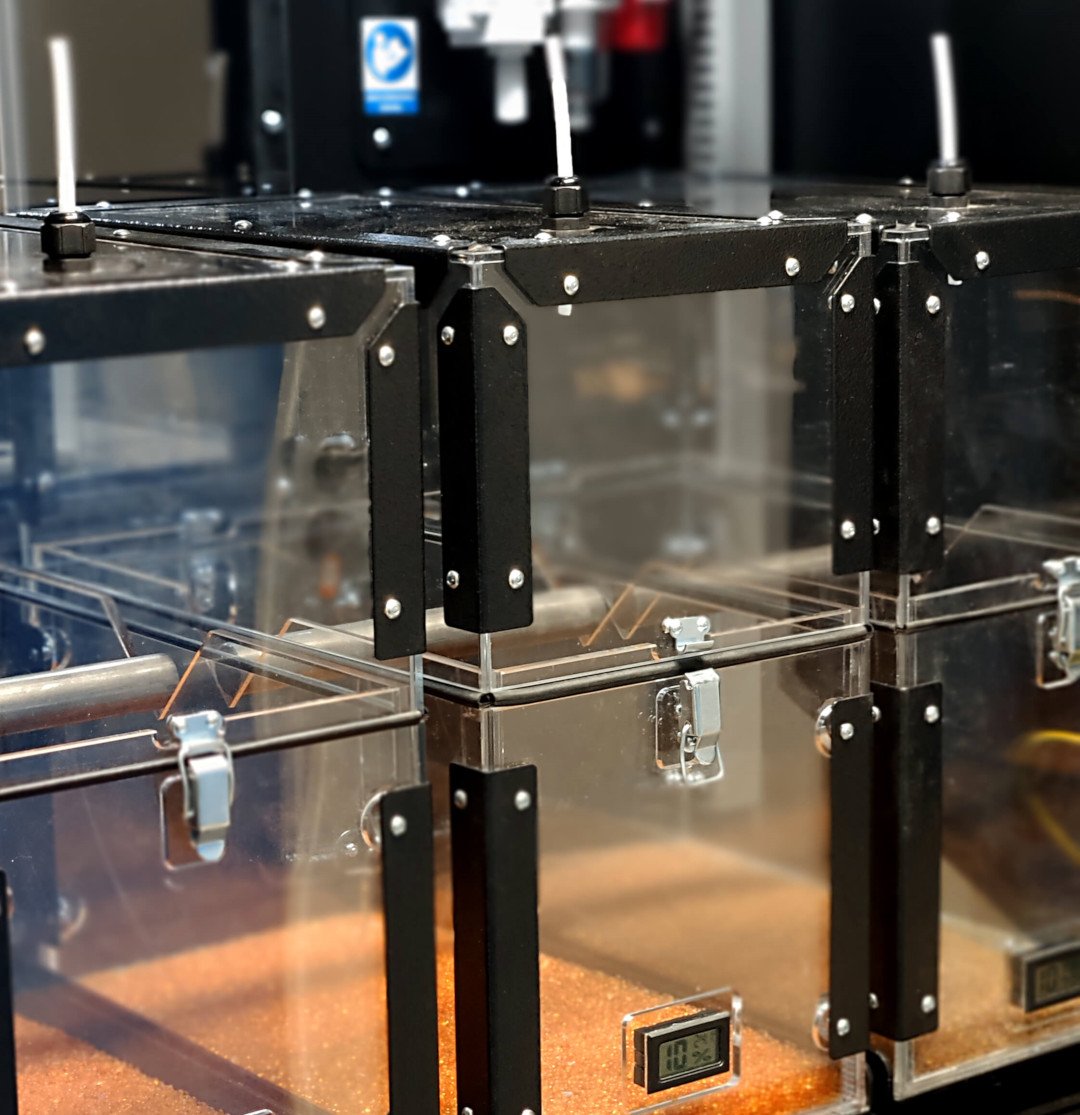

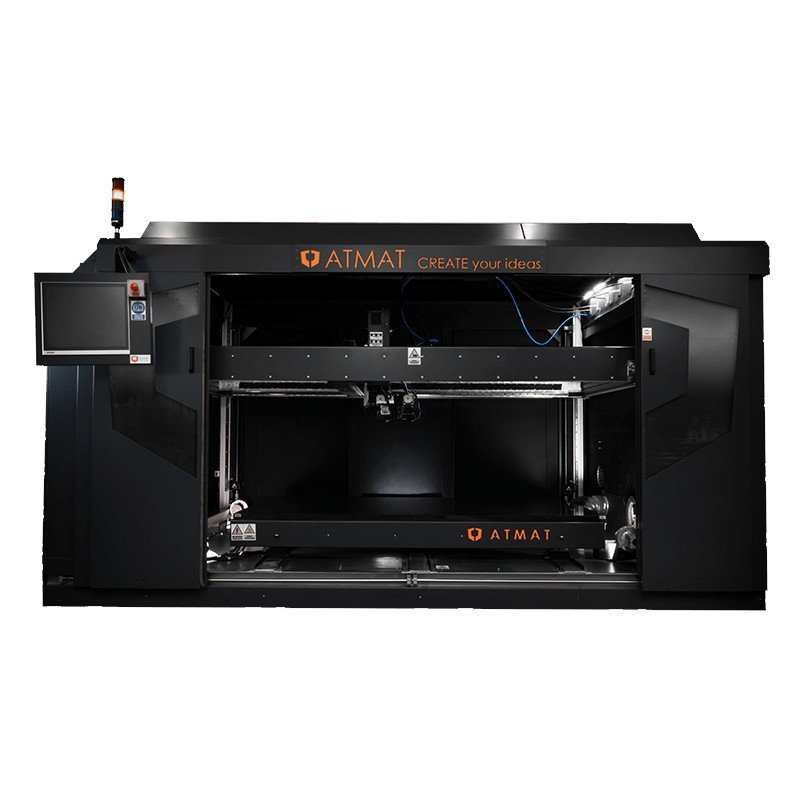

Capacious filament cabinet

The printer is equipped witha filament cupboard, which allows to accommodate three filament reelsup to 10 kg each.This solution guarantees long-lasting printing and continuity of work without the need to replace materials. Additionally, the cabinet has been equipped withdehumidifiersto absorb humidity from the air.

Spacious filament cupboard.

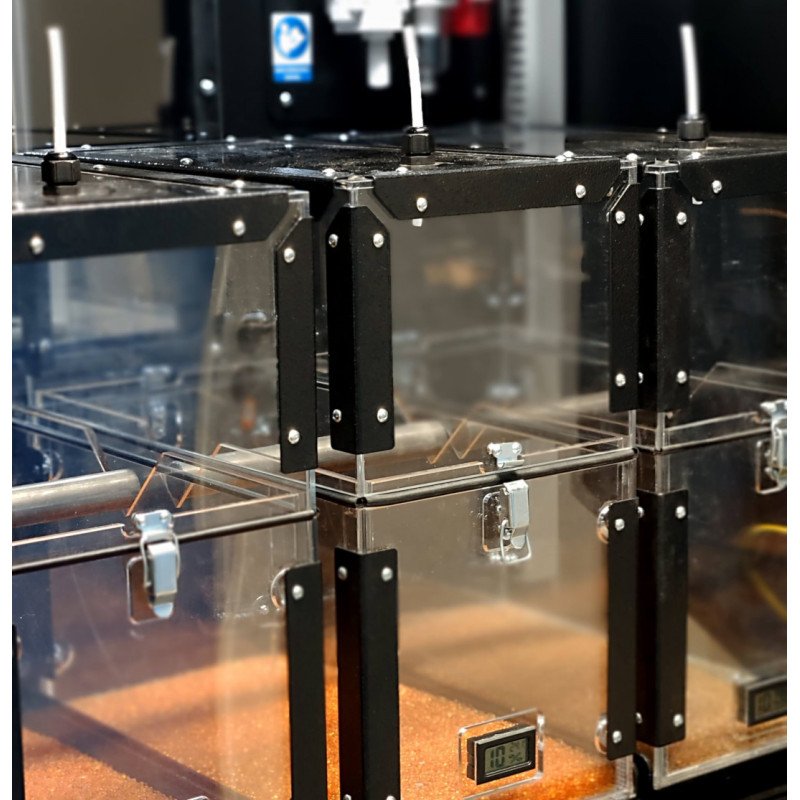

Heated working chamber

Constant temperature in the chamber is a key function affecting the operation of the device. Theheated working chamberis essential for printing from demanding materials used in the production of elements used in the industry.

Heated working chamber.

Intelligent control systems

The printer is equipped withintelligent control systemsthat ensure quick response to problems that arise. In the event of a power failure, the printing process can be resumed from the point of completion,which in the case of prints lasting several days guarantees stability and uninterrupted production. The device also has a filament sensor, as well as automatic nozzle height calibration, semi-automatic table levelling, semi-automatic filament replacement and automatic XY chassis levelling.

Intelligent work control systems.

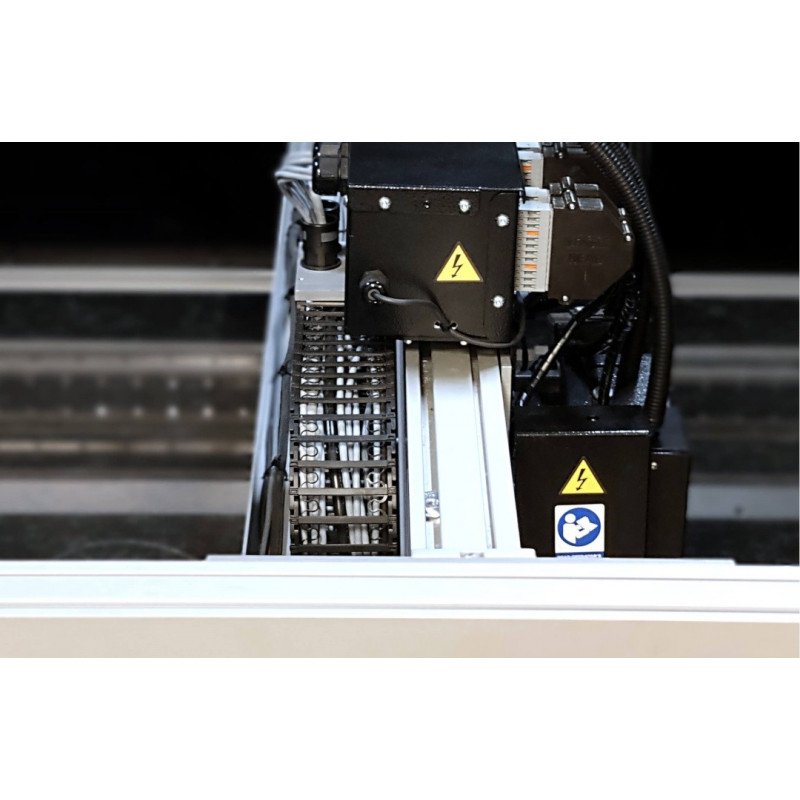

Magnetic drive

The motion of the X and Y axes is realizedby a magnetic linear drivewith an absolute encoder. This guarantees higher speeds, acceleration and more accurate positioning. The drivehas no mechanical partsthat can be damaged. The encoder allows continuous reading of the position in which the head is located, so there is no material displacement in the printer, each layer is always applied in the right place.

Magnetic drive in ATMAT Jupiter.

Resume printout after power outage

In case of a power outage, the user has the possibility to resume the printing process. This guarantees a stable and uninterruptible process for several days and reduces material losses. After the power supply is cut off, the controller saves the current position of the head, so that when the power is restored, the user can resume the printout in the control panel.

Resume printout function.

ATMAT Jupiter printer specification

| Technical Specification | |

|---|---|

| Printing technology | FFF (FDM) |

| Work area | 2000 x 1000 x 1000 mm |

| Case | Stable construction built with aluminum sheets. Light column and safety switch on the outside of the housing. Separate cabinet for the pillars. |

| Printing environment | Closed working chamber with temperature control |

| Maximum chamber temperature | 45°C |

| Working platform | Automatic table calibration, 6-zone working platform heating system |

| Working table material | Granite slab |

| Maximum working table temperature | 100°C |

| Nozzle diameter |

The main head: 1 mm, 1.5 mm, 2 mm, Auxiliary head: 0.5 mm, 1 mm, 1.5 mm |

| Number of heads | 2 |

| Number of extruders | 3 |

| Extruder type | Direct |

| Maximum head temperature | 340°C |

| Layer height | 0.2 mm to 1 mm |

| Nominal print speed | 200 mm/s |

| Print speed in HQ mode | 100 mm/s |

| Maximum travel speed | 300 mm/s |

| X/Y axis positioning accuracy | 50 μm |

| Positioning accuracy of the Z axis | 10 μm |

| Software package | Simplify3D |

| Software supported file formats | .stl, .obj |

| Supported materials | PLA, PET-G, PA, ABS* Supporting: PVA * for limited geometry prints |

| Diameter of material | 2,85 mm |

| Form of material | Reel |

| Supported spool masses |

3x 2.5 kg / 4 kg / 8 kg |

| Communication | USB storage medium |

| File format supported by the printer | .gcode |

| Control | Touch control panel with proprietary software |

| Remote preview | - |

| Working environment temperature | from 10°C to 30°C |

| Power supply | 400 V / 50 Hz |

| Maximum power | 2500 W |

| Average power consumption for printing with PLA | 2700 W |

| Dimensions | 3825 x 2375 x 2750 mm(width x depth x height) |

| Mass | 3000 kg |

The set includes

- ATMAT Jupiter 3D printer

- Service kit

- Four filament reels 8 kg

- Technical documentation

Useful links |