- EOL

|

Attention! The product has been discontinued. Check other products in category. |

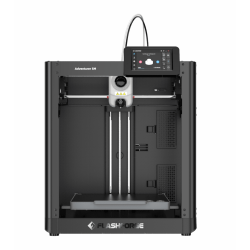

Product description: 3D Printer - Snapmaker v2.0 model F350

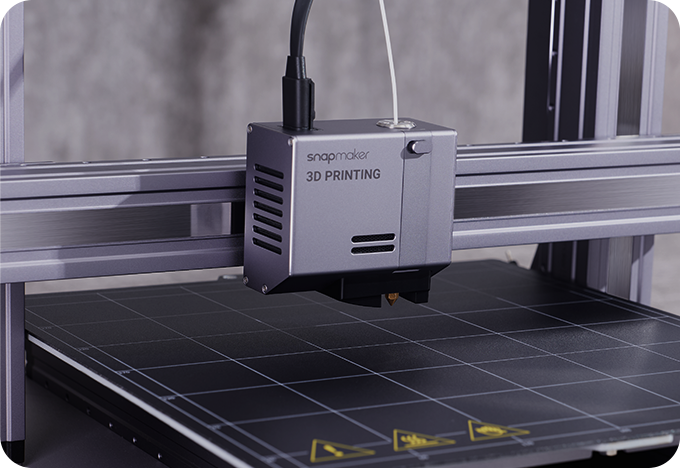

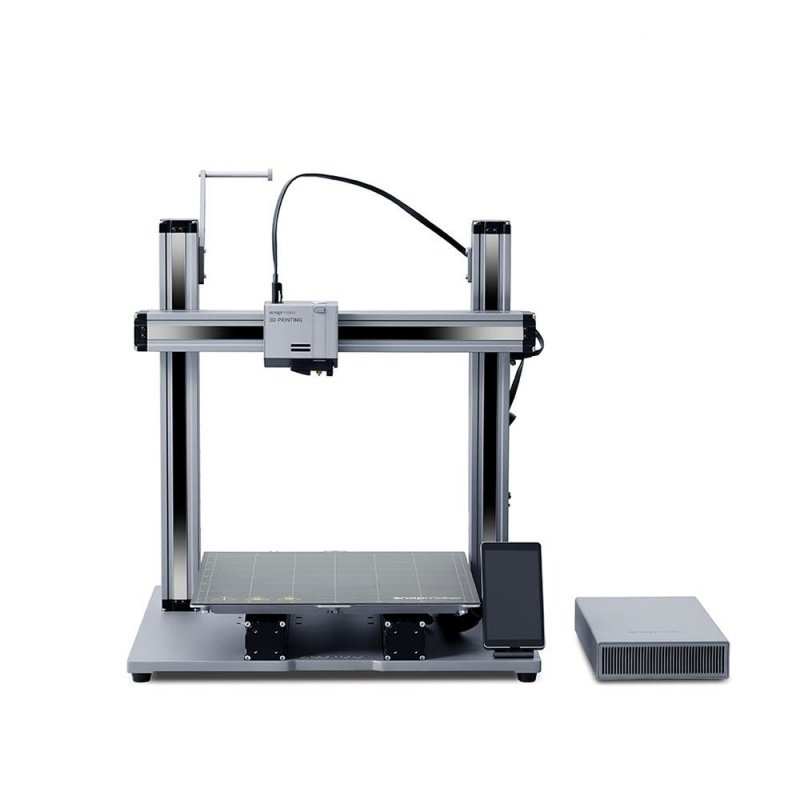

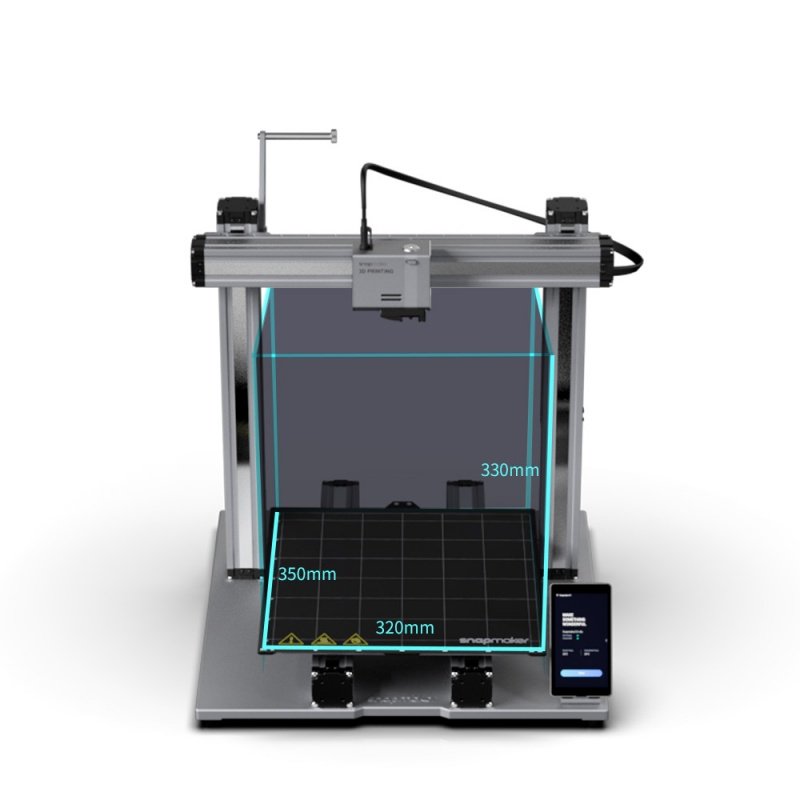

The Snapmaker 2.0 F350 3D printer features an updated 3D print head. The design of the F series has been made entirely of metal, which makes the device much more stable. The assembly process itself is well described in the included manual, so it should not cause any difficulties even for beginners. The working area of the F350 version is 320 x 350 x 330 mm. The printer has been equipped with a new print head, thanks to which printouts look even better than ever. The printer uses 1.75 mm diameter filaments. Snapmaker F350 is also equipped with improved linear guides, thanks to which the whole device works much quieter.

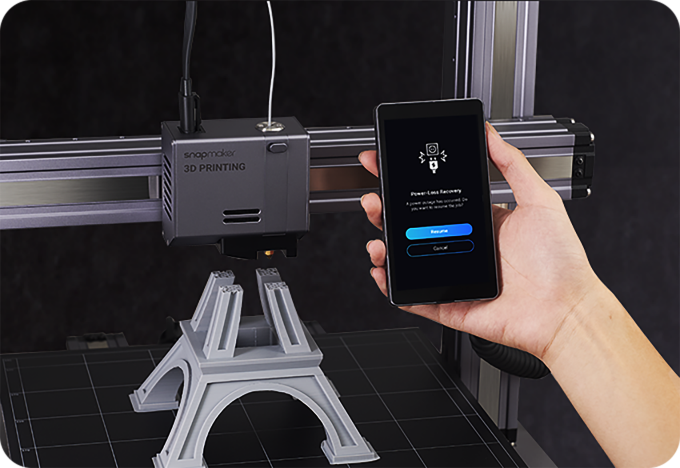

3D printing module in action.

3D printing, Snapmaker's flagship feature in a new edition

Stable construction, as well as the latest modules created by Snapmaker allow to make prints with high precision and in a relatively short time. F series printers are great machines for beginners who want to start their adventure with 3D printing without any modifications to the printer. The control interface is based on Android, which is very user-friendly and does not require special preparation before starting work. More advanced users can make changes to the print parameters while the device is working. The device works well with both basic materials, such as PLA or PETG, and more advanced materials, such as ABS, ASA, using the printer housing. Flexible materials are also not a problem for Snapmaker, it has been equipped with an extruder direct, which perfectly deals with this type of materials. New control systems responsible for the movement of linear guides were also applied, thanks to which the operation of the printer is much quieter.

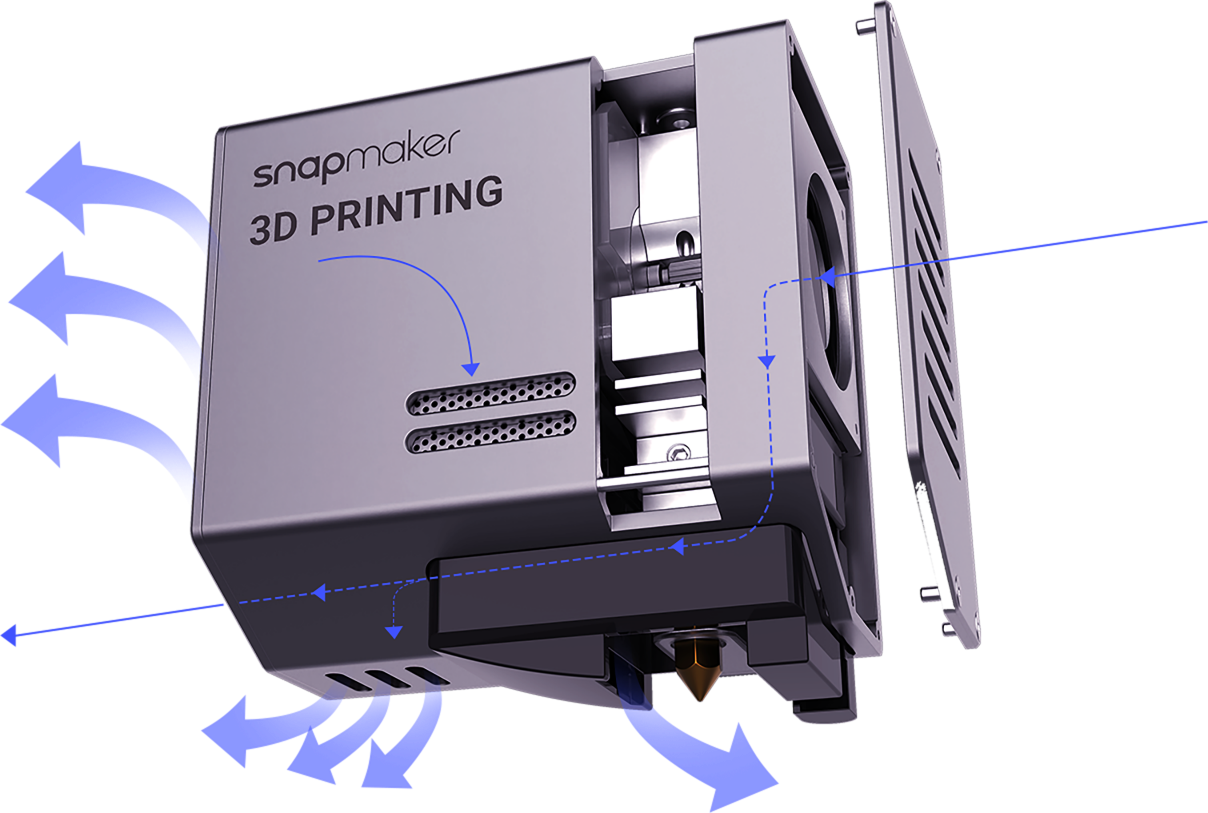

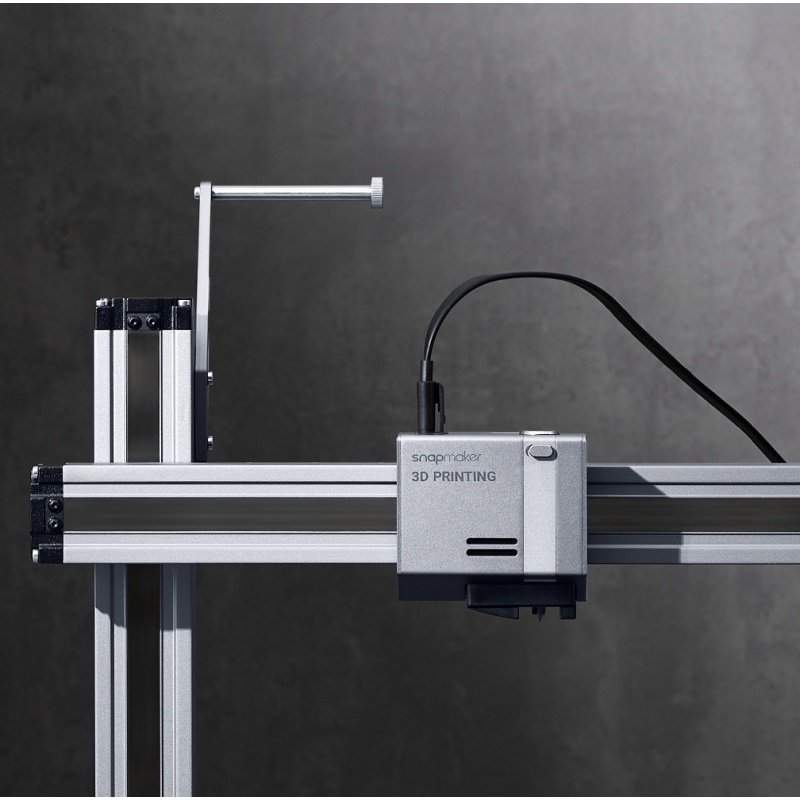

Redesigned printhead

The new print head has received a number of changes, corrections were made, which significantly improved the cooling systems. The control algorithm has also been improved, thanks to which printouts are even more precise and made much faster.

Many materials, many possibilities

The printer supports many materials such as PLA, ABS, PETG, TPU, PP, WoodFill and LayBrick. If Snapmaker is equipped with an additional enclosure, it is also possible to print with ABS or ASA material. You can choose a layer thickness between 0.05 and 0.3 mm.

Automatic levelling of the work surface

The 3D printing module has a built-in proximity sensor, which allows for automatic table calibration. The manufacturer has also equipped the printer with a manual calibration option, intended for more advanced users.

End of filament sensor

Inside the printing module there is also a sensor constantly checking the presence of filament threads, if the filament runs out, the printer will stop printing, and after refilling the material it is possible to resume printing in the same place.

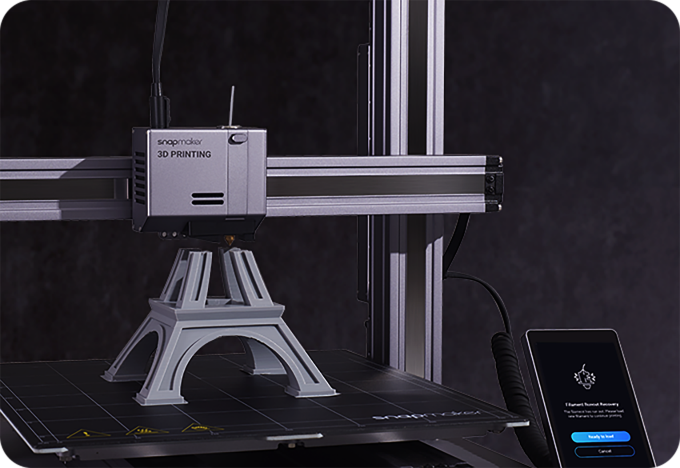

Continue working even after a power loss

The manufacturer has also prepared for possible problems with power supply. In case of power failure, the printer will stop working. The printer will keep all settings and the time of interruption in its memory, so you can resume printing exactly where you left off

The device is built with modules that make it easy to expand.

Snapmaker 2.0 F350 modular design

All Snapmaker printers are designed to be modular. Like other Snapmaker products, the F-Series is also fully modular. This allows you to fully customise the functionality to your needs by, for example, purchasing an additional laser module and the necessary accessories.

Extremely easy to assemble!

Modular design of Snapmaker 2.0 makes the process of assembly of the device very easy. In addition, the motors and control electronics are built into the linear profiles, and the plates to which the components are screwed are permanently attached to the linear systems. Such a solution is very convenient and user-friendly for beginners. Unlike amateur counterparts, which we have to assemble for hours, Snapmaker 2.0 will take only a moment to assemble.

The assembly process is simple and fast.

WiFi control and touch control panel

For complete convenience in configuring , the printer is equipped with a WiFi communication module. This allows you to remotely upload and update files using devices connected to your local network. The touchscreen features Android and an ARM Cortex-A7 processor, making it easier than ever to control your printer!

Making Snapmaker 2.0 Easy to Use

The device comes with software and hardware routines that are sure to make using it easier. Auto workbench leveling eliminates the hassle of manually calibrating the platform every few prints. Restoring work after a loss of voltage gives a great comfort, we do not have to be afraid that during the accidental disconnection of the device from the power supply we will lose our work. Improved in relation to the previous version of the device print cooling allows us to create elements that will be partially in the air without supports. Flexible adhesive pad makes the printout stick to the table without any additional preparations. We also do not have to use tools to unstick the printout from the platform, just bend it and the printout will fall off by itself.

Are you afraid that you will not be able to handle the device? Then you are wrong! The manufacturer provides a manual that explains step by step how to assemble the device and how to configure it for specific functions, this is a huge asset.

Snapmaker 2.0 F350 Specifications

| Basic Information | |

|---|---|

| Colour display: | 5" touchscreen |

| Frame material: | aluminum alloy, steel |

| Communication: | USB drive, USB cable, Wi-Fi |

| Supply voltage: | 100 V to 240 V AC |

| Supported systems: | Mac OS, Windows, Linux |

| Dimensions of assembled device: | 506 (L) x 495 (W) x 580 (H) mm |

| Working area for 3D printing: | 350 (L) x 330 (W) x 330 (H) mm |

| 3D Printing | |

| Nozzle diameter: | 0.4 mm |

| Maximum print nozzle temperature: | 275°C |

| Maximum work platform temperature: | 80°C |

| Layer resolution: | 50 to 300 microns |

| Supported materials: | PLA, ABS, PETG, TPU, PP, WoodFill, LayBrick |

| Filament diameter: | 1.75 mm |

| Supported file formats in Snapmaker Luban: | .stl, .obj |

Kit includes:

- Linear modules (with TMC2209 chips)

- 3D printing module

- Controller (based on Cortex-M4 processor)

- 5" intelligent touch screen (operated by Android system, based on Quad Core A7 1.1 GHz processor)

- Power supply with power cables

- Magnetic table for 3D printing with pad for increased adhesion

- Device base with non-slip feet

- Work platform base

- Mounts for linear modules

- Mounting for touch screen

- Cable kit for connection of modules, workbench, linear modules and screen

- Converters for cables

- Fiber holder

- Flash drive

- Set of tools (screwdriver with interchangeable tips, wrenches, pliers, tweezers, spatula)

- Set of screws

- Plates for leveling the work platform

- Manual of assembly and use of the device

- Spool of filament (1 kg of PLA)

Advanced printer for many applications!

Work performed in the electronics workshop is not only soldering and taking measurements with a multimeter and oscilloscope, but also very often with machining and 3D designing. When we want to design a case or assembly elements with non-standard shapes and dimensions on our own, then we can do the whole process at home! In such and similar tasks Snapmaker 2.0 F350 will prove to be a perfect solution.

Versatile uses of the Snapmaker 2.0 F350 3D printer

The Snapmaker 2.0 F350 is the larger of the two F-Series printers. With F series printers, we can create a variety of physical objects. For example, using the 3D printing module, we can print a custom housing for our electronic device project, such as a pocket audio amplifier class A.