Table of Contents:

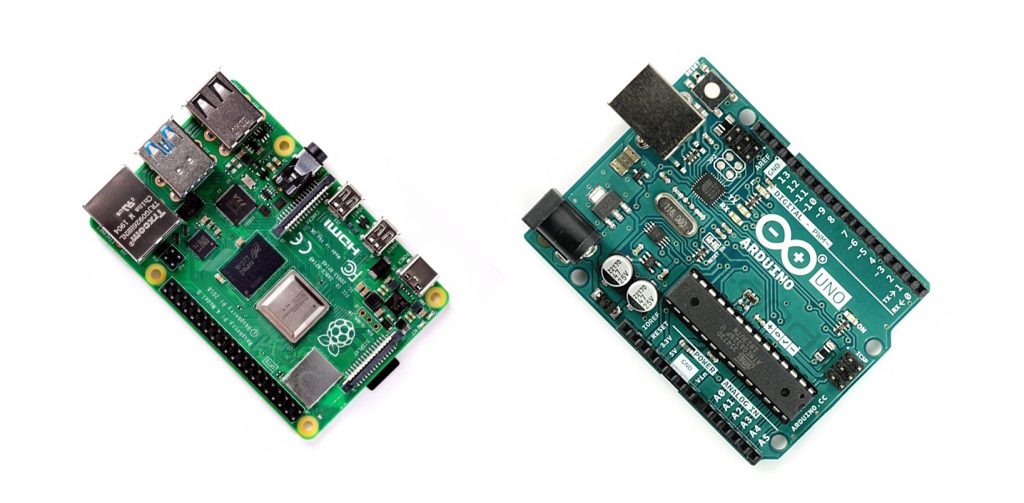

Raspberry Pi and Arduino are names familiar not only to specialists in the field of electronics and robotics, but also to hobbyists who dabble in the role of designer in their spare time as part of developing their hobbies. These minicomputers (Raspberry Pi) and modules with a microcontroller (Arduino), highly appreciated by professionals, are so functional and advanced that they are often used in industry.

-

Raspberry Pi and Arduino

Raspberry Pi – what is it?

A mini-computer whose dimensions (not counting its height) resemble a credit card. Its latest version – the Pi 4B model – is equipped with, among other things, two micro-HDMI ports that support images up to 4K resolution, four USB ports (two of them 3.0 standard), a 100/1000 Mb/s Ethernet port and a USB-C port for power supply. It also has Bluetooth 5.0 and dual-band WiFi. The power of this little device already surpasses personal computers and laptops from a few years ago. When compared to ENIAC, the first machine that can be considered a computer, built between 1943 and 1945, which was housed in a 72 square meter room, weighed 27 tons and used 140 kW of electricity, the Raspberry is impressive. It perfectly demonstrates the pace at which humanity is evolving, and with it the technologies we know (and do not know). This evolution is also taking place in industry, where we tend to automate processes and use Internet-of-Things (the so-called Industry 4.0) solutions, which aim to connect the world of production and machines with the world of information technology and the ubiquitous connection to the Internet.

Smart industry and Raspberry

This is where Raspberry Pi can work very well, as it successfully deals with Internet of Things (IoT) solutions used in homes and apartments by hobbyists. Industrial IoT systems are often very expensive solutions that not all businesses can afford. Thanks to Raspberry, you can create, for example, an industrial print server, a surveillance system or an automatic lighting system in a simple and much cheaper way. Of course, these are not all possible solutions – manufacturers of industrial systems have quickly recognized the potential of Raspberry and started to develop their own drivers based on Raspberry.

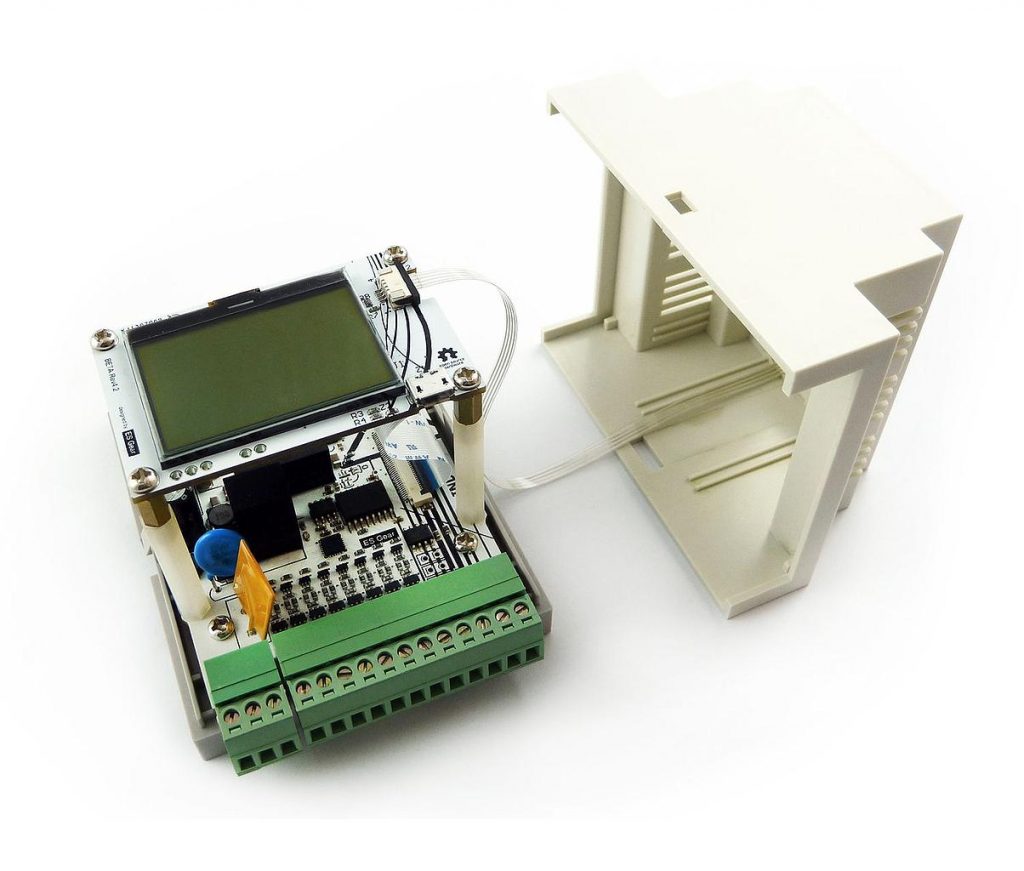

The Raspberry Foundation itself helped in this process by releasing “industrial” versions of the minicomputer, called Compute Module, which allow for easy integration of the Raspberry with external devices produced on a large scale. And that is how such solutions as PiXtend or KUNBUS came about: they are Raspberry-based industrial controllers, which are in no way inferior to solutions such as Siemens, with the necessary interfaces such as CAN, RS485, RS232. Such solutions are more expensive when compared to designs based on RPi alone, but they are closed in appropriate housings mounted on a DIN rail, thanks to which they can be easily combined into systems and installed in control cabinets. We use the Raspberry-based Put to Light system ourselves and it works flawlessly. Of course, such solutions need software to work. PLC controllers are programmed in various languages that are standardized and defined in the IEC 61131-3 standard. Many developers of programming environments for PLC systems have included the RPi in the list of supported devices, and for example CODESYS and REX CONTROL SYSTEM allow you to create programs for Raspberry-based drivers. However, this is paid software, but this is where the OPENPLC environment comes in.

Arduino in industry – what you should know

Arduino is a popular module with a microcontroller, although it is actually the name for a whole range of devices with different hardware capabilities. Generally speaking, it was created with a scientific application in mind – it was mainly intended for students and for educational purposes. However, it soon became apparent that its capabilities went far beyond the didactic. And while Raspberry Pi can be used to further modernize production by introducing IoT solutions, Arduino can be used to construct solutions for industry. The years of development of the platform, a series of innovative projects created by the Arduino community (more or less related to industry), led the creators of the platform to take steps to obtain the certifications required by the industry. So it happened, and the group of enthusiasts who created production automation solutions on their own in their workshops and even companies were joined by companies that developed ready-made, fully professional PLC controllers based on Arduino. Probably for this reason, many warehouses already have fully functional Put to Light or Pick by Light systems based on Arduino in use. Another interesting solution is a machine for sorting and packaging pills, developed by two University of Toronto students based on the Arduino Nano module. An employee of the JF Machines created a system that controls the circulation of ink and temperature in digital printers and also informs about possible malfunctions in the equipment. It is worth mentioning here professional PLCs based on Arduino, such as Industrial Shields or Industrino, whose capabilities are comparable to traditional PLCs and are used in large production plants.

-

The Industrino module

As you can see, seemingly simple devices – Raspberry and Arduino – can be used as industrial solutions, although they were designed as solutions for the scientific field and for hobbyists. After years of presence on the market, they received appropriate certificates and came in versions intended for embedded systems, creating professional solutions as an alternative to the existing ones. Of course, with a little effort and knowledge, you can also create industrial automation systems on your own, as many small businesses have probably already found out.

We invite you to familiarize yourself with our offer of modules, extensions and ready-made kits for Arduino and Raspberry Pi.

How useful was this post?

Click on a star to rate it!

Average rating 0 / 5. Vote count: 0

No votes so far! Be the first to rate this post.