Table of Contents:

A 3D printer – practical applications

Mass production of elements with a repeatable shape and parameters has been possible for years. However, the production of only one 3D piece for test purposes, i.e. as a prototype or for specific applications, has always been problematic – even in industrial production or design offices. The more complicated and smaller the project was, the more commitment and time had to be invested in its realization, and it required a higher level of expertise from the person carrying out the project. That is why 3D printing proved to be such a revolution – and it just had to happen. In the following article, we will discuss what 3D printing is, what types of 3D printing can be distinguished, and how it can be used in medicine, industry, aviation, the automotive industry, and other areas of human life.

3D printing – what industries is it used in?

- medicine

- education

- architecture

- industry

- entertainment

- culture and art

- games and entertainment

Where did 3D printers come from?

Most people didn’t even hear about 3D printing until the 21st century. However, the very idea of creating a machine that would allow a physical reproduction of a technical drawing appeared in the 20th century. What is more – it was then successfully implemented and patented. However, it was not 3D printing as we understand it today, because it used liquid crystal polymer – the parts were produced in a layer-by-layer fashion, using a laser. In contrast, modern 3D printers usually work on a different basis: the form is built up layer by layer using filaments (plastic fibers) that are melted in a nozzle. Only the order in which the shape is formed has remained the same – both stereolithography (the earlier form of 3D printing) and modern 3D printers start from the lowest layers. It is interesting to note that the “right”, or rather the most popular FDM technology was developed only two years later. But the biggest boom in this area occurred in the mid-2000s, as a result of the creation of a 3D printer that could be used at home.

The use of 3D printing in different industries

3D printing in medicine

The most spectacular 3D printing projects are those used in medicine. They can successfully replace some structures (e.g. bones) that were destroyed, damaged or not developed at all in one’s body. In 2015, physicians from Poznań implanted a large printed part to replace the patient’s pelvic bone damaged by the tumor. At that time, it was one of the largest operations of its kind in the world.

Today we are able to print not only artificial bones but also soft tissue. In 2018, the media reported that scientists at North Carolina succeeded in printing a fully “developed” auricle (i.e. with nerves and blood vessels). Muscles and bones were also created in a similar way. The printed organs are not yet used in humans, but animal testing have been successful so far. Of course, traditional filaments cannot be used to print tissues and organs – instead, 3D printers use a whole range of specialized hydrogel materials in which living cells are embedded. In this way, scientists (and probably doctors in the future) can obtain an organ that is perfectly acceptable to the recipient’s organism without the risk of a histoincompatibility reaction. This means that in the future, instead of waiting for a donor, organ recipients could receive organs developed for them. Because the whole process is closely linked to tissue engineering, printing organs is not just a regular 3D printing technique – it is a new branch of bioengineering, called bio-printing, which combines many different scientific fields and is often closer to stereolithography than to FDM.

This spectacular process is not the only way 3D printing is used in medicine. It is now also widely used in dentistry, which successfully adapts all technical innovations (e.g. stomatology also uses 3D modeling). Prosthetic laboratories are very interested in using models that simply need to be taken out of the 3D printer, as there is no need to spend time on milling or casting. It is worth noting that the first applications of 3D printing technology were similar to those in medicine – the technique was used to produce preoperative models. For example, as early as 2014 in Gdańsk, doctors performed medical procedures on a 3D model of the skull, which made surgery on the real skull much easier. Such methods are used in many specialties, especially in heart surgery.

3D printers in architecture

Let’s start with an aspect that seems obvious in the case of using 3D printing in architecture: building models. Designers have always made spatial mockups, but it took time and great craftsmanship. With access to 3D printers, the entire process has been greatly simplified – with tools like these, it is now possible to prepare any mockup quickly and at a lower cost: all you need to do is send a correctly converted 3D model (which should be easy for any experienced architect) to the printing machine. You might think that size constraints limit the use of 3D printing in architecture to prototypes, but nothing could be further from the truth. In 2014, one of Shanghai’s companies boasted that it could “print” prefabricated elements for the construction of a single-family house. And although their slogan of “houses printed in 3D” has so far been nothing more than marketing bait, since the assembly process of the printed elements takes place on a regular construction site – the way has been shown.

The marriage of architecture and 3D printing has great prospects thanks to an idea that originated in the Netherlands. One of the local start-ups decided to build a pedestrian bridge over one of Amsterdam’s canals, which involved programming robot arms to control large-scale welding machines; most interestingly, they worked with steel. The bridge itself, once installed in the right place, is secured with many sensors to record the performance of the entire structure. Another breaking news – about a 3D-printed house of almost 100m2 – came from France. Several organizations from Nantes (including the local university) worked together to realize this project, and the building was printed using foam and concrete in several dozen hours. The assembly took a little longer.

When analyzing the use of 3D printers in construction and architecture, interior design should not be forgotten. Compared to building structures, making furniture may seem like a piece of cake, but remember that furniture can be large as well. What is more, the final structures must pass appropriate stress tests and offer their users the level of safety and comfort they expect. IKEA, a Swedish group, is one of the pioneers in manufacturing furniture using 3D printing. Their collection of printed furniture was launched onto the market in 2017.

3D printing in industry

Word is getting around that a 3D printer could soon be standard equipment for many companies, just like a traditional printer, plotter or scanner. And while some industries will never need this technology, companies such as design offices, engineering firms, and industrial enterprises cannot exist without it. 3D printing makes prototyping processes easier, faster, and simpler – a technical drawing that is converted to a 3D design and then printed out allows you to create a perfectly sized prototype without wasting material. In addition, this technology enables full repeatability when you need to print multiple copies, for example, for testing purposes. 3D printing is increasingly used in the production of dedicated housings and cases for prototypes and trial series of products.

Another application of 3D printers involves so-called reverse engineering. It is based on forms that are scanned with a 3D printer and then – after appropriate processing – printed using the FDM method. Such a variant works perfectly when a pattern already exists and only needs to be multiplied. The form to be scanned can be prepared manually by the designer, but it is also possible to scan an existing element, for example a part of a structure that needs to be replaced.

3D printing in aviation and space industry

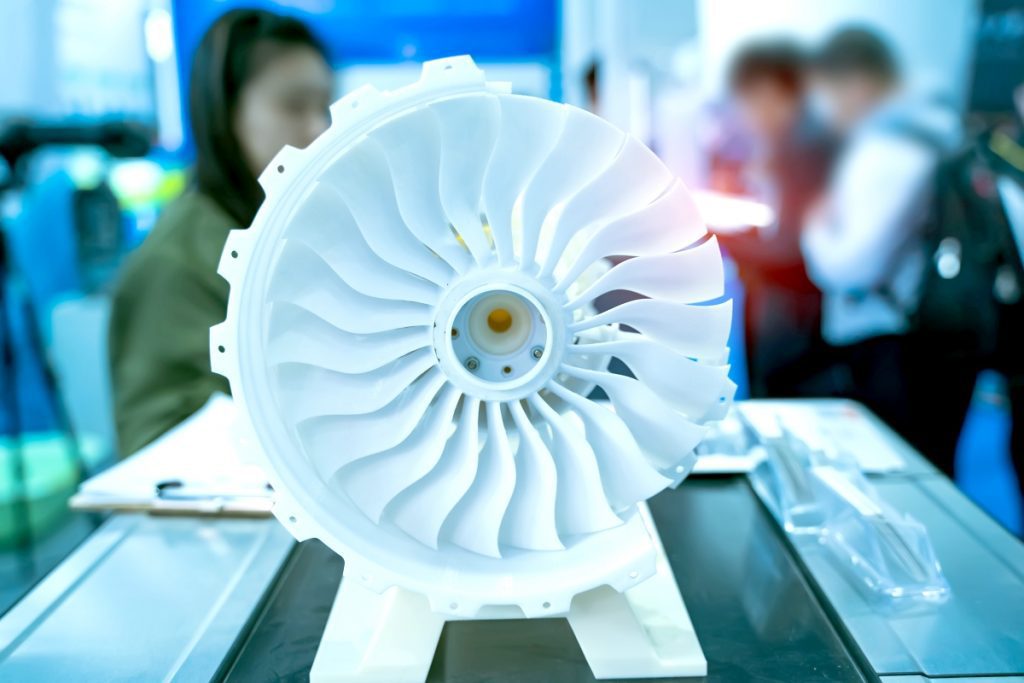

Aeronautics is one of the most demanding industrial sectors and requires the use of materials that are highly resistant to very difficult environmental conditions (pressure, sunlight, humidity, overloads, vibrations, temperature variations, etc.). It turns out that some filaments used in specialized 3D printers meet these strict requirements. Some market giants, such as Boeing, already want to use 3D printing for their purposes. Perhaps one of the most important tasks of 3D printing today is the rapid provision of spare parts. Metal filaments used in FDM can be processed in a completely different way than the usual foundry metals. The internal structure of elements created by with 3D printers using metal filaments can be complex – not either full or empty inside, but transpicuous, filled with a complex system of internal supports. There are many advantages of such a solution: the lower weight of the element, the smaller amount of material used in production, no loss of material, and finally – lower production costs. However, the aircraft spare parts themselves are not the only case where 3D printing can be applied in aeronautics.

3D printing of instrumentation and tools for the production of parts for the aviation industry is already bringing phenomenal results. Perfectly printed tools facilitate and accelerate production processes. 3D printing is also an invaluable method in prototyping processes for aviation engineering centers and scientific units – as early as 2015 Wojskowe Zakłady Lotnicze in Bydgoszcz informed about the successful adaptation of this technology to their needs. 3D printed prototypes can be quickly tested in order to modify the design and, if necessary, re-manufacture the mold. Furthermore, Polish Aviation Museum in Krakow decided to use this technology to reconstruct the elements of the hull of a Caudron Renault.

Aeronautics is “just” one step away from space technologies. 3D printers took that step a long time ago. In 2014, the crew of the International Space Station showed the first 3D print produced in Earth orbit (it was an extruder plate). Then, other test elements were produced as well – they were then transported to Earth to be tested under laboratory conditions to see if and to what extent their parameters differed from those achieved on Earth. 3D printing is very important on space missions because it gives mission participants a great deal of independence from supplies – the crew can make small items themselves if necessary, rather than waiting for delivery. In 2019, NASA announced their bold plans to build an entire spacecraft to serve as an orbital 3D printing plant. The project is intended not only to provide a specific solution to existing needs, but also to demonstrate and test potential technological possibilities.

3D printers at home and…

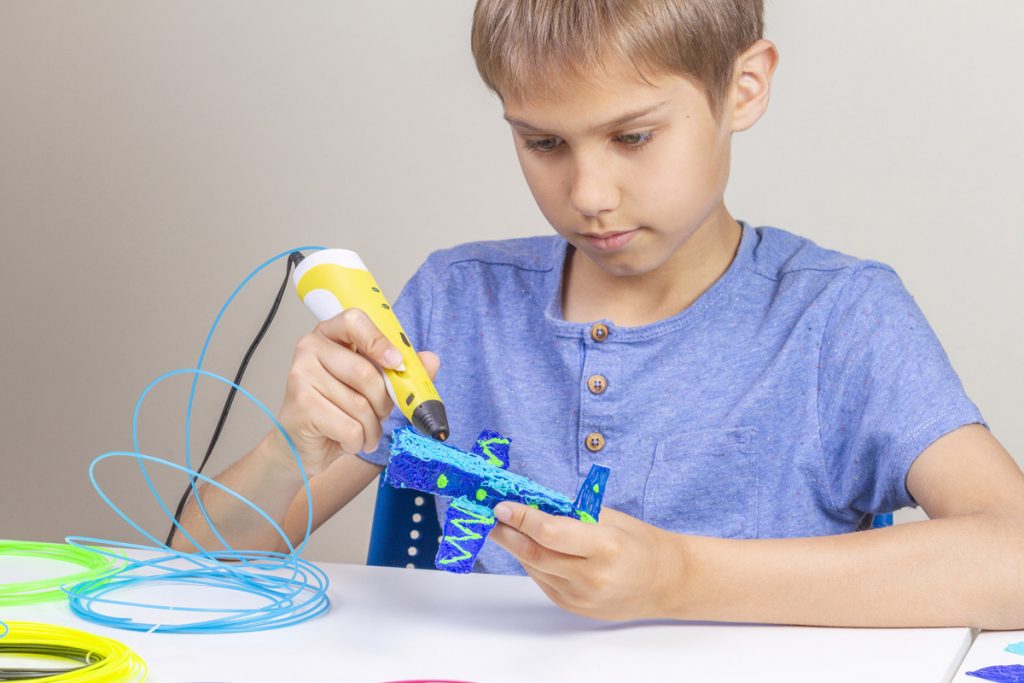

It’s hard to say whether 3D printing would have become as famous in the media as it is now if it had not ended up in private homes at some point. However, 3D printing technology has reached private users a bit indirectly. The “distant relatives” of 3D printers – the popular 3D pens – were the first to make a career among amateur users. They look like ballpoint pens, but with plastic filaments instead of ink; the heated filament freezes in the air immediately after leaving the tip of the pen, so you can “draw” more or less complex spatial structures. However, if you look at some projects made by the enthusiasts of these gadgets, you will see that even with such a limited version of 3D printing, you can achieve not only satisfying but even artistic results. The first 3D printers for home use appeared around 2006 and immediately won the hearts and workshops of enthusiasts.

The range of possible applications is wide – from simple figures, gadgets and collectors’ items inspired by computer games, to elements for model constructions and structures to be published on social platforms under an open source license. Of course, there are also numerous CAD files to pay for – there are whole platforms on the web that specialize in offering this kind of ready-made projects.

It was no surprise that artists, as one of the most creative social groups, were quick to adopt 3D printing technology. For example, at the Technopark in Łódź, there is a 3D printed copy of the sculpture of Uszatek, a famous Polish teddy bear. The original sculpture is located on Piotrkowska street. Meanwhile, in Ptaszkowa in Małopolska, 3D printing was used to copy a valuable work of art created by Wit Stwosz. The copy is exhibited in the church where the bas-relief was found several years ago; the original itself was brought to the museum for conservation purposes. A similar method of securing monuments was used in Konin Żagański, where some figures from the sixteenth and seventeenth centuries found in the local church were copied using 3D printing. In addition, there is a start-up company called Twinkind in Hamburg, Germany, which uses reverse engineering to print the customer’s miniature “mini me”: they scan the customer’s body and recreate it using FDM technology.

3D printing in education

In the age of multimedia technology, the imagination of young people is doing quite well, but it can be supported for example thanks to 3D printers. They can be used to create spatial models of geometrical solids, chemical compounds, or DNA helices. Children and young people learn and understand information in a completely different way if they can use many senses, for example, the sense of touch. The models, which are printed in 3D, encourage the young people to experiment. The mere participation in the process of designing and printing 3D structures is another great advantage. Universities are also making more professional use of 3D printers – they use them for prototyping, research experiments and reverse engineering.

The future of 3D printing

3D printing is an area that is still developing in many different directions. 3D printers are getting smaller –and bigger at the same time, to enable printing of different forms regardless of their size. Scientists are constantly working on new materials that can be used as filaments – more durable, more resistant to external conditions, more flexible, more permeable or insulating, neutral to the body or even cooperating with it (e.g. for transplantation purposes in medicine). Many industries see in this area the opportunity to obtain a material tailored to their needs, so the range of products on offer is constantly growing. Perhaps in the future, 3D printing technology will make it possible to eliminate the need for organ donors and the risk of transplant rejection, and to replace all missing body parts with printed organs. We will probably print food, including meat. You can clearly see that 3D printing is becoming increasingly popular in many areas of human life, and it’s hard to imagine living without it now.

A wide range of printers, filaments and accessories for 3D printing can be found on our website in the 3D / CNC printing section. On the Internet you will certainly find other interesting 3D models that can be easily created at home. Check them out yourself!

How useful was this post?

Click on a star to rate it!

Average rating 5 / 5. Vote count: 1

No votes so far! Be the first to rate this post.