3D printing is a term for various production techniques in which a product is built up layer by layer. A 3D printer adds material to an object until the desired shape is reached. This is a form of additive manufacturing which is an excellent alternative to sub-additive manufacturing. A great benefit of 3D printing is the fact that it generates less waste of material. This production technique is becoming more and more popular around the world, and thus, now you can buy a 3D printer without spending a fortune. The capabilities of such devices are diverse, and a wide variety of materials can be used for this kind of production, including plaster, gold, bioplastic, ceramic, photopolymer, wood, titanium, ABS, sand, PLA, polyester and epoxy. 3D printing is also used for the production of functional parts. It makes it possible to produce a real object; however, it is necessary to draw it on a screen using a computer-aided design (CAD) tool first. Then the 3D file is sent to a specific software which cuts it in slices and sends to the printer. Eventually, by using deposits or other material, the 3D printer creates layer by layer to get the final product.

3D PRINTING

3D printer - Creality K2 Plus Combo

Creality presents its first printer using innovative multi-material printing technology! The CFS system, which is equipped with the printer, can hold four filament spools,...- Sale

- SPECIAL OFFERS

- Sale

3D printer - Original Prusa XL - 5 heads - assembled

Original Prusa XL is an advanced CoreXY 3D printer offering a 360 x 360 x 360 mm build volume that enables multi-material printing using five heads . It is equipped with a...3D printer - Original Prusa CORE One+ - assembled

The Prusa CORE One+ is a fully assembled CoreXY 3D printer offering high print quality, speed, and reliability. Equipped with a closed, heated chamber , a steel...3D Printer - Original Prusa CORE One+ - self-assembly kit

The Prusa CORE One+ is a closed CoreXY 3D printer combining high printing precision, speed, and reliability. Equipped with a steel exoskeleton , a modern Nextruder...3D printer - Original Prusa MK4S - assembled

3D printer from the Czech company Prusa, known among 3D printing enthusiasts. The device is based on a 32-bit motherboard and supports Input Shaper and Pressure Advance...3D printer - Original Prusa MK4S - set for self-assembly

3D printer from the Czech company Prusa, known among 3D printing enthusiasts. The device is based on a 32-bit motherboard and supports Input Shaper and Pressure Advance...Filament Devil Design PLA 1,75mm 1kg - Black

Filament Devil Design is made of PLA, used as cartridge for 3D-printers and printing pens. The diameter is 1.75 mm. The set includes 1kg filament in Black color.Nozzle cleaning needle 0,4mm - 5 pcs

Nozzle cleaning needle for 3D printers. Dedicated to nozzles of 0.4 mm diameter . Allows you to clear the hole sealed with a filament. Thanks to its high flexibility, the...Nozzle 0,4 - filament 1,75mm - brass

Original nozzle from Creality. It is compatible with the hotends found in Creality's Ender-3, Ender-5, CR-6 series 3D printers and can also be used in: Ender-6, CR-10, CR-10...Filament Devil Design PLA 1,75mm 1kg - White

Filament Devil Design is made of PLA, used as cartridge for 3D-printers and printing pens. The diameter is 1.75 mm. The set includes 1kg filament in White color.Filament Devil Design PETG 1,75mm 1kg - Black

Filament Devil Design is made of PET-G, used as cartridge for 3D-printers and printing pens. The diameter is 1.75 mm. The set includes 1 kg of the fi lament in Black...Nozzle 0.4 mm MK8 - filament 1.75mm - copper

Nozzle 0.4 mm is suitable for most of the existing heads. Filament is 1.75 mm. External M6.Platform Sticker Creality Ender-3

Self-adhesive overlay with dimensions 235 x 235 mm , which is a base for 3D printing. Dedicated to Ender-3 printers. It is an original part of the printer manufacturer,...Knife for processing 3D prints - deburrer with 10 spare blades

Knife designed for processing 3D prints. It has profiled interchangeable blades , whose curved shape makes it easy to reach even the most difficult to reach details of the...StepStick DRV8825 Stepper Motor Driver

Stepper motor's driver based on the system DRV8825, allows you to control the motor with a current consumption of up to 1.5 A (with cooling of up to 2.2 A) per coil, at...Printer nozzle 0,2mm MK8 - filament 1,75mm - copper

Nozzle with a hole of 0.2 mm is suitable for most available printheads in printers 3D. Supports filaments with a diameter of 1.75 mm. It has M6 threads.Stepper motor driver A4988 RepRap - red

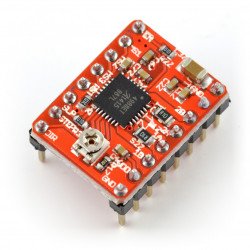

Stepper motor controller based on A4988. Powered from 8 - 35 V, with a maximum current consumption of 1 A per coil. Maximum resolution: 1/16 steps.Creality nozzle 0,4mm - filament 1,75mm - copper

Original Creality nozzle . Intended for use in hotends of a few selected models of 3D printers from the Ender-3 and CR series (the full list below). The product is made of...Bigtreetech TMC2209 v1.3 Stepper Motor Driver

Stepper motor driver, whose supply voltage ranges from 4.75 V to 28 V DC . The maximum current consumption per coil is 2 A (RMS). The driver can operate in two modes: step /...See also

3D printing is the future of prototyping

The term "3D printing" covers a number of different technological processes in which material is combined or solidified under computer control in order to create a three-dimensional object from the material added by an appropriate system. It can be available in various forms, such as liquid particles, powder grains, resin or molten plastic. One of the key advantages of 3D printing is the ability to produce very complex shapes or geometries, and the prerequisite for producing any 3D printed part is a digital 3D model or CAD file. This greatly facilitates the design and rapid production of elements - that is why 3D printers are often used for rapid prototyping of mechanical elements.

History of additive methods

The idea of 3D printing first appeared in the 1970s, but it was only in the late 1980s that the first FDM printers appeared, which are still popular today. In the 1990s, 3D printing techniques were considered only suitable for producing functional (with some limitations) or visual prototypes. At that time, rapid prototyping was the only application of 3D printing systems. Nowadays, the precision, repeatability and range of materials used in 3D printers have increased to such an extent that some printing processes are considered more profitable as an industrial production technology than the classic methods previously used - especially in small series production. Thanks to this, the concept of additive manufacturing has permanently entered the industrial vocabulary.

Different types of 3D printing technology

There are many different 3D printing processes. They can be grouped into several categories. The main differences between the processes lie in the way the layers are deposited. The most popular methods use melting the material to extrude the layers. The most popular method of this type - FDM - produces an object from the so-called molten filament, which immediately hardens behind the nozzle, creating layers. Powder bed fusion techniques include several processes that can be used with a wide range of materials and structures. These techniques include selective and direct laser sintering. These methods offer higher resolutions than FDM, but are much more expensive. Other methods harden liquid materials using various advanced technologies such as stereolithography or photopolymerization. Such systems spray a layer of photopolymer onto the object and selectively harden it with UV light. Using multiphoton photopolymerization, it is easy to produce objects even below 100 nm, but these methods are difficult and expensive.

3D printing - FAQ

3D printing ✔️ is the opposite of subtractive manufacturing, which involves cutting or hollowing out a piece of metal or plastic using a milling machine or similar devices. 3D printing allows you to produce complex shapes using less material than traditional production methods.

The type of 3D printing material depends on the technology the 3D printer uses. And there are plenty of them: plastics ( filaments )✔️, powder materials, resins , metals and alloys, carbon fiber, graphite and graphene, nylon, paper and even food products!

We have posted a comprehensive guide in the 3D Printing section of the Botland Blog. The filaments are made of thermoplastic materials. Some of them are synthesized from start to finish based on artificial substances, others, such as the most popular PLA (polyactide) filaments , are made from natural raw materials.

When it comes to choosing 3D printing software, it is worth choosing Autodesk Fusion 360, Autodesk AutoCAD, Ultimaker Cura, TinkerCAD, SketchUp or MeshLab. You can also start with Morphi. It's a 3D software development app developed by a New York startup and intended for use on tablets by beginners.

The three fundamentals of 3D printing costs are, of course, the 3D printer itself, the cost of the material, usually a spool of filament, and electricity consumption. We can add additional accessories. You can read more about 3D printing costs and how to reduce them on Botland Blog .

First, it is worth learning the basics - what 3D printing is and how individual parts of a 3D printer work, including the frame. Once we have a working 3D printer and filament, it's time for design files. We download ready-made designs from the Internet, run the machine and print.

Take a soft cotton cloth and apply a small amount of liquid polishing paste to it. Then apply this to the 3D print surface in small circles until all the paste is rubbed in. After the process is completed, the surface will be slightly smoother, but these are just the basics. You can find more ready-made solutions in the 3D printing postprocessing category.