Motors are essential components of all electrical devices. They are used in machines and robots, allowing them to perform specific work and actions, move and respond to user commands. An electric motor converts electrical energy into mechanical energy, so that a specific reaction and action takes place. We can distinguish between a DC electric motor and an AC electric motor. In addition, there is another division which includes a vibrating, commutator, vibrating and brushless motor. There is also a tunnel drive, which can be used to create a model of a fake jet. Electric motors have found their application in vehicles, household appliances, building automation systems, robots, production plants, factories and warehouses, wherever human duties are taken over by machines. In Botland's offer you will find a wide range of simple and more advanced engines, whose voltage is 12V or 24V. So adjust both type and voltage to the design requirements of your robot.

Motors

Mini DC Motor MT71 1,5-6V with Washer

Small metal motor powered from 1.5 V to 6 V. Idle current 22 mA. Dimensions: 24.4 x 12.8 mm. Speed approx. 3500 rpm.Wheel + DC Motor 65x26mm 5V with 48:1 Gear

Wheel with a tyre diameter of 65 mm and a width of 26 mm, with motor powered with voltage of 5 V with a current consumption of approx. 180 mA. The engine has a gear 48:1,...Mini DC Motor MT64 3-6V - justPi

Small metal motor powered by a voltage ranging from 3 V-6 V. No-load current 30 mA/ 3 V. Dimensions: 18.6 x 15 x 12 mm. Speed: approx. 14,000 rpm.Mini vibrating motor 10x2.7mm - 5V

Miniature 2.5V to 5V vibration motor with 10mm diameter and 2.7mm thickness.Wheel + DC Motor 65x26mm 5V with 48:1 Gear + wires

A wheel with a tyre of 65 mm diameter and 26 mm width, together with a motor powered by 5 V , with a current consumption of about 180 mA. The motor has a gear ratio of...Stepper Motor with 28BYJ-48 Gear 5V/0,1A/0,03Nm with ULN2003A driver

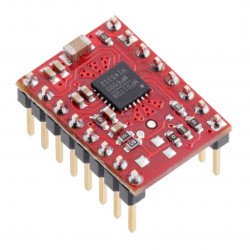

This five-wire stepper motor features a Darlington driver. It has an integrated 64:1 gear ratio. It operates at 5V and draws 100mA per coil. The gear holding torque is...Mini Vibration Motor 10x2,7mm - 3V

Mini vibration motor powered by 3 V . Idle current consumption is 80 mA . The motor is 10 mm in diameter and 2.7 mm high. The module has two cables which are removed from...Stepper Motor JK42HS40-0504 200 steps/rotations 12V/0,5A/0,43Nm

A bipolar stepper motor, four wired. Has a resolution of 200 steps per rotation (1.8 degree). It is powered with a voltage of 12.0 V, consumes 500 mA per coil. Torque is 4.4 k...Stepper Motor JK42HS34-0404 200 steps/pr 12V/0,4A/0,25Nm

A bipolar stepper motor, four wired. It has a resolution of 200 steps per rotation (1.8 degree). It is powered with a voltage of 12.0 V, consumes a current of 400 mA per coil....Stepper motor 28BYJ-48 5V / 0.1A / 0.03Nm with ULN2003 controller

Five wire stepper motor with driver on Darlington chip. It has an integrated 64:1 gear ratio, is powered by 5 V, and draws 100 mA current per coil. The holding torque...DC Geared Motor with encoder-SJ01 (6V 160RPM 120:1)

Motor with the 120:1 gearing, 160 rpm, torque of 0.8 kg*cm (0.07 Nm). The device has a quadrature encoder with a resolution of 8 impulses per revolution (after the transfer of...Motor DC 6V, 11500RPM - Pololu 1117

DC brush motor. Nominal voltage 6V. Speed 11500 rpm. Maximum current 800 mA.Solenoid Valve 12V - 0,02-0,8MPa

The device supports the control of fluid flow using a computer or microcontroller. The valve is powered with the voltage of 12 V. The pressure range: 0.02 to 0.8 MPa....Stepper Motor JK57HS56-2804 200 steps/rot 2,4V/2,8A/1,26Nm

A bipolar stepper motor, four wired. Has a resolution of 200 steps per revolution (1.8 degree). It is supplied with the voltage of 2.4 V, consumes 2800 mA on the coil. Torque:...HP Motor with 30:1 Gear - Pololu 1093

Miniature high-power Pololu motor with 30: 1 gear, has 1000 rpm, the torque is 0.6 kg * cm (0.059 Nm).DC motor with 1:48 gear 3-6V with double sided shaft 200RPM

Plastic DC motor with 1:48 gearbox, supplied at 3 V to 6 V. It can easily be used when starting various projects. The double shaft rotates at speeds of up to approx. 200 rpm....Commutator motors - simple and versatile design

The simplest DC motor is a commutator motor, in which the supply voltage is fed to the rotor circuit through sliding brushes and the rotor element - the commutator, created by a package of copper plates. The current flowing through the rotor circuit creates a magnetic field that interacts with the magnetic field of the stationary stator made of permanent magnets. The continuity of rotation and direction of rotation is maintained by switching the polarity of the supply voltage by the commutator - then the current in the rotor circuit changes direction, which translates into the reversal of the magnetic field between the rotor and the stator. Due to its properties, the brush motor is universally applicable.

Brush motor - what else is worth knowing about it?

Thanks to their simple structure and the ability to control the rotational speed, commutator motors are particularly popular in power tools, household appliances, robots, and broadly understood automation systems. Our offer includes a wide selection of commutator motors in geared and direct drive versions, as well as a low-speed motor.

BLDC - a future-proof solution among electric drives

BLDC motors , unlike commutator motors, do not transmit power to the rotor via brushes. The stator is an electromagnet powered by direct voltage. The rotor is made of permanent magnets and, depending on the design, it can be built into the stator or rotate inside the stator. The voltage polarity is changed using a static commutator, which is based on transistors. The stator's magnetic field sets the rotor in rotation by interacting with the magnetic field coming from the rotor's permanent magnets. Brushless DC motors are a design characterized by high efficiency, durability and low energy consumption while maintaining smaller dimensions compared to commutator motors. They are used, among others: in electric vehicles, fans and air conditioners, electronics, as well as in RC modeling. We invite you to check out our offer of Redox brushless motors, available in various power variants! 12V and 24V electric motor. Other categories include, among others: mounting elements , servomechanisms , accessories and many other components.

Stepper and vibration motors - ideal for robots and signaling devices

A stepper motor is a special type of brushless motor whose rotor rotates not continuously, but discretely, and is powered by voltage in a pulsed manner. Its technical parameters depend on the specific model. Applying a single pulse causes the rotor to rotate by one step, the rotation angle of which depends on the step resolution - the higher the step resolution, the smaller the rotor rotation angle after each supply voltage pulse. Stepper motors are used in broadly understood robotics, CNC machines, printers, analog clocks and vehicle components, as well as in industry. Another unusual design is the vibration motor, which differs from ordinary electric motors in that an asymmetric load is placed on its shaft, which, under the influence of rotation and its own mass, creates a proportional centrifugal force causing the motor to vibrate. Vibration motors are used in most mobile phones, game consoles, voltage presence indicators, and massage devices. All products and accessories in our offer come directly from manufacturers or proven suppliers. If you have any questions or concerns about electric motors (or any other product), you can contact our customer service department. Botland store - fast and safe delivery. Order the products and we will take care of the rest (including delivery). The product added to the cart allows you to proceed directly to payment or continue shopping. It is also worth creating an account on our website.

Engines - FAQ

A DC motor consists of a stator, equipped with permanent magnets , and a rotating rotor with a winding connected to a commutator. Applying voltage to the brushes sliding on the commutator creates a magnetic moment that sets the rotor in motion.

A DC electric motor, also known as a DC, brush or commutator motor, is widely used in many areas - from electronics and household appliances, through robotics, to power tools and ventilation devices .