Equipping with vibration motors greatly expands the range of possible designs when it comes to creating your own electronic and mechanical designs. Advanced automatic systems that require continuous rotary operation can be equipped with these types of engines.

Vibration motors

Mini vibration motor 10x3,4mm - 5V

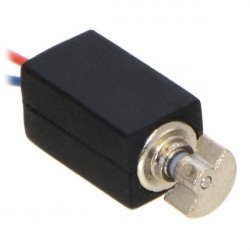

Mini vibration motor powered by 5 V. Module with a diameter of 10 mm and a height of 3.4 mm . Current consumption is 80 mA . The motor module has two wires.Mini Vibration Motor 10x2,7mm - 3V

Mini vibration motor powered by 3 V . Idle current consumption is 80 mA . The motor is 10 mm in diameter and 2.7 mm high. The module has two cables which are removed from...Vibration Motor 10 x 3,4 mm - Pololu 1636

Small motor generating vibrations of 0.75g amplitude. It consumes about 60mA of current when powered by 3 V.Grove - vibration motor + module

The module contains a miniature DC vibrating motor. It is very easy to use and is equipped with Grove interface which makes it easy to connect it with Arduino and Raspberry Pi.Mini Vibration Motor 10x3mm - 3V

Small vibrating motor with a diameter of 10 mm and a height of 3 mm . Powered by 3 V . Current consumption is 80 mA . The motor has two red and blue wires with the...Mini vibration motor 10x2mm - 3V

Miniature vibrating motor . It is powered by a voltage of 3 V. The dimensions of the module are equal: diameter 10 mm, height 2 mm . Current consumption is 80 mA . The...Vibration Motor 11,6x4,6x4,8mm - Pololu 2265

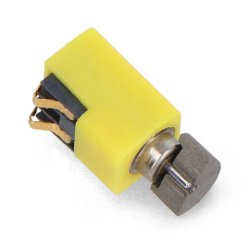

Vibration motor with displaced mass placed on the shaft. It draws approximately 60 mA of current with a 3 V supply.DRV2605L - haptic motor controller - Adafruit 2305

The module is designed to control haptic (touch) motors: buzzers and vibration motors . The product extends the possibilities of using this type of engine. It allows, among...DFRobot Gravity - vibration motor module

Module from the Gravity series with vibration motor for Arduino controlled with the PWM signal, low and high status. The supply voltage is 5 V.Mini vibrating motor 10x2.7mm - 5V

Miniature 2.5V to 5V vibration motor with 10mm diameter and 2.7mm thickness.Mini vibration motor 12x3,4mm - 3V

Small vibrating motor with a diameter of 12 mm and a height of 3.4 mm . The module is supplied with a voltage of 3 V . The current consumption is 80 mA . The motor has...Mini Vibration Motor MT63 1,5 V

Small metal vibrating motor powered by 1.5 V. Idle current 180 mA. Dimensions: 17 x 10 x 12 mm.Vibration Motor 10 x 2,0mm - Pololu 1638

A small motor generating vibrations of 0.75 g amplitude. It draws about 60 mA of current at 3 V.Vibration Motor 8x3,4mm - Pololu 1637

Small motor that generates vibrations with an amplitude of 0.75 g. It consumes about 60 mA of current when supplied with 3 V.See also

Vibration motors are manufactured based on two technologies - ERM and LRA. The first technology uses the unbalanced mechanical load on the rotor by mass. This load as the shaft rotates generates a centrifugal force. As a consequence, vibrations arise, which we owe the name of this group of engines. The second technology - LRA - uses a linear resonator in which a small ferromagnetic element is connected to a spring. Under the influence of a magnetic field, it vibrates and drives a vibration motor.

Both types of vibration motors are available in the offer of the online shop with electric motors Botland. Here you will find products that differ in both physical sizes and detailed technical parameters. In complex projects, vibration motors can be connected in series, e.g. 4 3-volt motors and powered by a battery or a 12V power supply. Choose the motor that perfectly matches your mechanical project now!

The professional use of vibration motors

The vibration motors are designed to perfectly generate and handle vibrations. These are devices designed and adapted to drive vibration installations. When it comes to the use of vibration motors, these types of components can be found in many different kinds of applications such as transport vibrating chutes, vibrating pipes, screening conveyors, screening machines and sorters. In addition, vibration motors are also used for vibrating feeders, crushing grates, vibrating stands, resonating conveyors, compactors and vibratory mills.

Obviously, in the field of DIY projects, our imagination is the main driving force determining what components and components we will use to build a given model. Nevertheless, as can be seen in the examples above, vibration motors are among the more advanced components and are mainly used in industry and professional tasks.

Vibration motors – mechanical technology implemented in the first mobile phones

Unbalance is the core of the vibration motors. Unbalance is understood as a constantly rotating mass. It is unevenly distributed in its rotational symmetry, as a result of which it causes constant vibration as it rotates. These types of vibrations can be modified with weights and counterweights. The main axis of operation of vibration motors is the use of the above phenomenon put in motion of unbalance.

Haptic technology and vibratory alerting are also important. These are the two most popular methods of implementing vibration signals in electronic devices. The first, haptic technology, uses vibrations with different duration of pulses between individual vibrations, which allows you to easily distinguish the signaled information from each other, and vibrational alerting uses the effect of a linear increase in vibration intensity. The first mobile phones are a perfect example of using the above technology.

As we remember well, these devices had been implemented with a built-in small vibration motors that signaled an incoming call or text message with short vibration signals. Later, in the case of an incoming message, they vibrated the word "SMS" with Morse code. Nowadays, vibration signals are also used in many software applications for smartphones, but the technology of generating vibrations itself has been significantly modified and changed.

Vibrator motors – other practical applications

The applications of vibration motors are, in contrary to what we may think of them, very wide. Moreover, many models have been equipped with additional functionalities. Feedback is a good example. With the use of feedback in such devices, vibration motors can be used for maintenance-free cleaning of gutters in the event of clogging, e.g. with leaves.

The above cleaning methods require the use of motors with higher torque. On a smaller scale, regarding mini-motors, the devices are used in chemical laboratories for the preparation of emulsions, and in home applications as a drive for an electric toothbrush and a drive for an air pump for filling the cuff in an electronic device for measuring blood pressure and heart pulse. The electric motor can also be used in precision low-power drive systems.

If you are wondering which vibration motor to choose, please do not hesitate to contact us. The Botland team will help you choose the best product for your project!