Numerical processing machines, commonly referred to as CNC, are now the basis of the manufacturing industry. It is hard to imagine any factory today offering metal or woodworking services that would not even have one milling machine and/or CNC lathe. The development of electronics and the growing popularity of efficient stepper motors has meant that today small CNC milling machines can be purchased not only by companies, but even...modelers or amateurs of robotics.

CNC milling machines

Two Trees TTC-450 Pro CNC milling machine

The Two Trees TTC-450 Pro CNC router is a modern machine with a large work area of 460 x 460 x 80 mm , enabling precise engraving and machining of wood, acrylic, aluminum,...- Sale

3D printer - Snapmaker Artisan 3in1 Premium - laser module, CNC, 3D printing in enclosure

Snapmaker Artisan multifunctional device for printing, engraving and CNC machining, with a chamber ensuring user safety. In the Premium version, the manufacturer replaced the...Snapmaker 3D Printer v2.0 3in1 model A350T - laser module, CNC, 3D printing in enclosure

A set which includes Snapmaker A350T version 2.0 multifunction device and a chamber designed to increase safety while working with Snapmaker. The device is made entirely of...- Sale

Snapmaker 3D Printer Artisan - laser module, CNC, 3D printing in enclosure

3in1 set for printing, engraving and CNC processing, i.e. the Snapmaker Artisan multifunctional device with a chamber ensuring user safety. The device is distinguished by a huge...Two Trees CNC milling machine TTC3018S

The versatile Two Trees TTC3018S CNC machine combines engraving and cutting functions , offering a work area of 300 x 180 x 40 mm and precision down to 0.1 mm . With a...- Discontinued product

Two Trees TTC-450 Ultra CNC milling machine

The Two Trees TTC-450 Ultra CNC router is a versatile machine for metal and woodworking . With a 500W spindle motor, a large 460 x 460 x 100mm work area, and dual 12H...- Discontinued product

CNC router machine Two Trees TTC-450

TTC-450 offers a very large working area with dimensions of 460 x 460 x 80 mm , which expands the possibilities of the milling machine. Its operation will not be a problem...- Discontinued product

Two Trees TTC3018 Pro CNC milling machine

The Two Trees TTC3018 Pro CNC milling machine is a precise, compact milling machine designed for processing wood, plastic, aluminum, acrylic, brass, and other materials . It...- Discontinued product

See also

CNC milling machine – stiffness and clearance control

In order to consciously choose the right model of a CNC milling machine for the intended applications, it is worth learning a little more about the details of the construction and key parameters of this type of devices. The implementation of a supporting structure and a drive system that allows for feed in all three main axes is very important for the quality of the obtained machining results (machines with a larger number of degrees of freedom are usually not found among amateur and semi-professional solutions).

CNC milling machines - additional information about the structure

First of all, a CNC milling machine, or more precisely, its structure, should be stiff and free from unnecessary play (in all axes). Any inaccuracies of the machine will be reproduced in the detail, both as deviations from the set dimensions (e.g. too large hole diameters) and as "jags", ripples on flat surfaces, etc. visible to the naked eye.

Unfortunately, in the case of lower quality machines, bringing them to the desired level of accuracy (X-axis, Y-axis and Z-axis) is in many cases a complicated and often expensive task. Therefore, you should pay close attention to the type of construction profiles, their dimensions and the type of guide grooves - sometimes such seemingly insignificant details can affect the results of the work. We also encourage you to check out the CNC accessories category, where you can find, among others: various materials for processing.

SPINDLE POWER AND TYPE

Another very important element of the construction of a CNC machine is the spindle. It is an electric drive with a solid, bearing-mounted structure, used to directly transmit rotation to a tool - usually a milling cutter or drill. Spindle power depends on the rotational speed and torque - some types of materials (e.g. aluminum) must be processed at high speeds, but with relatively low torque. In turn, in the case of some steel alloys, it is recommended to significantly reduce the number of revolutions per minute, but high torque is important - that is why CNC milling machines for wood use different spindles than solid, expensive CNC milling machines for metal. While in the case of delicate, easily machined materials (e.g. plastics or soft wood), small spindles can be used, in the case of metal processing, solid drives with a power of over one kilowatt, equipped with powerful brushless motors, controlled by appropriate inverters, become necessary. .

It is worth adding that the demand for torque increases not only with the hardness of the raw material, but also with the diameter of the tool - it is difficult to imagine gouging material with a 16-mm cutter using a spindle that is adapted to tools with a diameter not exceeding several millimeters. .

WorkBee v2.1 CNC milling machine – a solid base for building your own CNC machine

The problem that a person interested in building their own CNC milling machine will sooner or later encounter is the creation of a sufficiently rigid supporting structure with small clearances and high positioning accuracy. The creators of the WorkBee v2.1 project are well aware of this, which is why they have introduced a kit for assembling the base of a large milling machine with a working area of up to 800 x 770 mm.

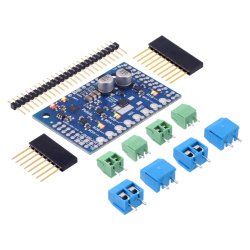

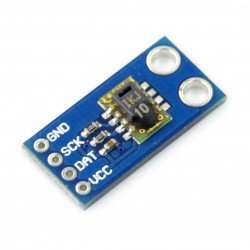

The whole is based on high-quality V-Slot and C-Beam aluminum profiles, and the trolley drive is provided by high-quality ACME screws. However, the set does not include the motors, spindle and controller - the choice of these elements is up to the user. Fortunately, it is not a problem today - our offer includes various types of stepper motor controllers, as well as the drives themselves, available in the most popular NEMA23 standard.

It is worth knowing that many designers of amateur CNC milling machines base their projects on controllers based on the Arduino platform - there is even free software available on the Internet, which greatly facilitates the integration of the entire CNC milling control system. We encourage you to check out the rest of the Botland store's assortment, divided into intuitive categories. If you have any questions, please contact us by e-mail, telephone or via the form available in the contact tab.

CNC milling machines - FAQ

A CNC milling machine is a type of machining machine in which the movement of the tool (or workpiece) and spindle rotation are computer controlled via a special controller . The use of CNC technology enables precise and repeatable creation of complex shapes.

A precise CNC milling machine is perfect for carving and engraving wood - e.g. Snapmaker v2.0, which, in addition to milling with a conventional spindle, can also perform laser engraving and print elements using 3D FFF (FDM) technology .

In the case of aluminum machining, it is necessary to use a machine with solid axle and spindle bearings, a rigid and stable structure and strong drives in the form of stepper motors . Therefore, an excellent choice when creating relatively small aluminum details will be the popular CNC 3040 milling machine with a working area of 300 x 400 x 70 mm.