Description

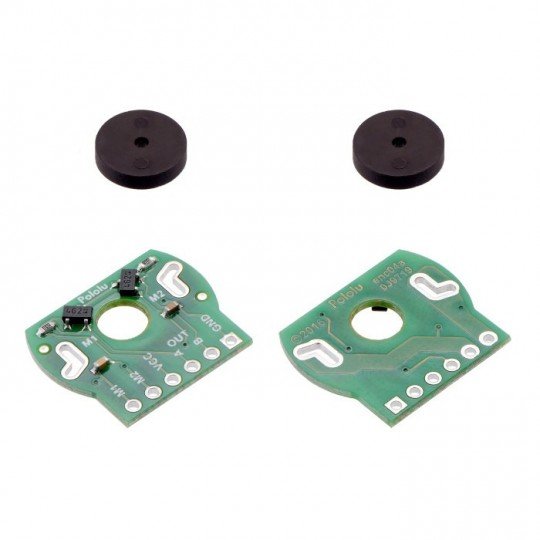

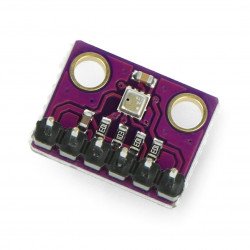

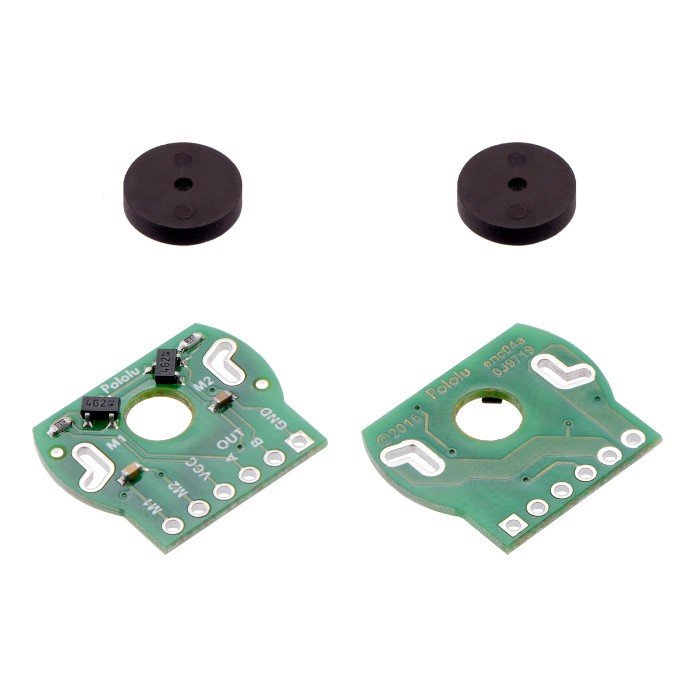

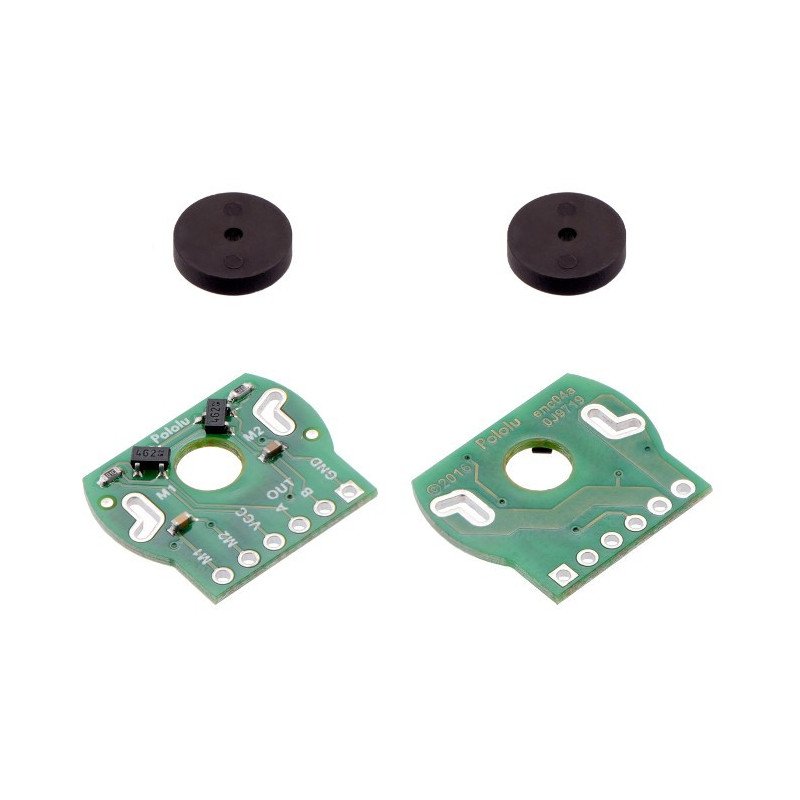

A pair of magnetic quadrature sensors, designed for installation in plastic mini angle motors from Pololu. The set consists of two boards with integrated sensors that use the Hall effect and two impellers with magnets. The set allows to obtain a resolution of 12 impulses per revolution, it is powered with the voltage ranging from 2.7 V to 18 V.

|

The sensors only work witha plastic mini motors from Pololuequippedwith biliteral, extended shaft. |

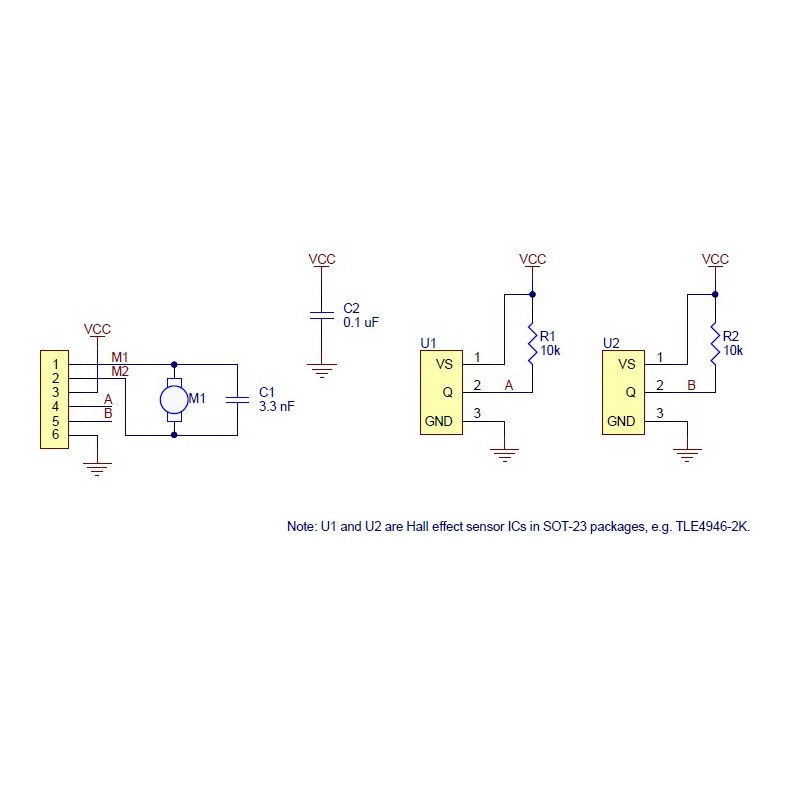

Operating principle of the encoders

Specification

- Supply voltage: from 2.7 V to 18 V

- Resolution: 12 impulses per revolution *

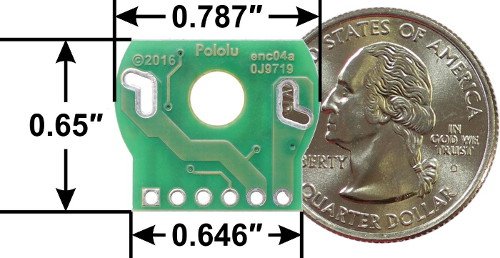

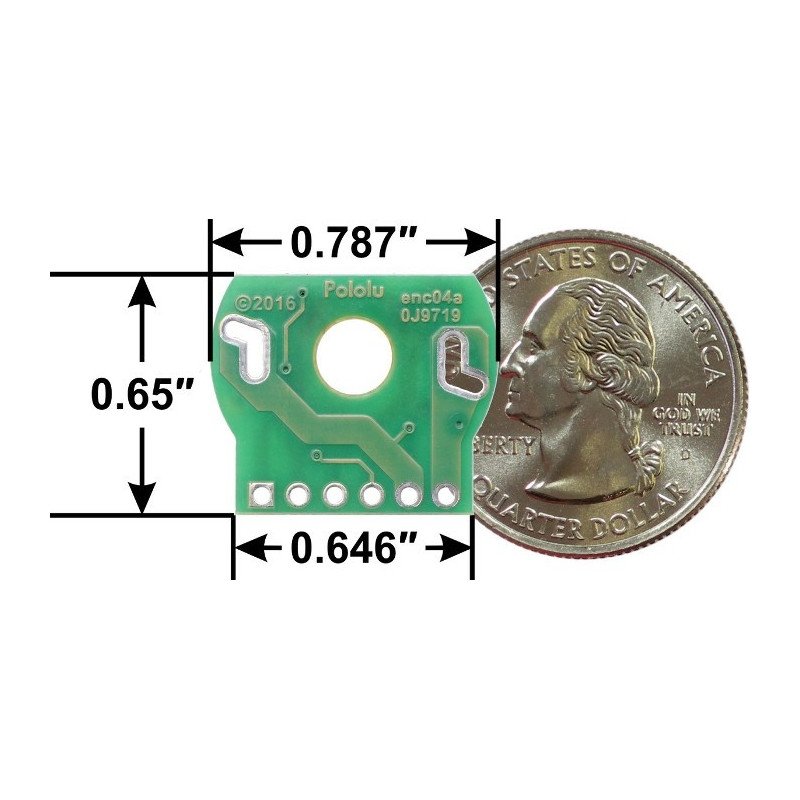

- Dimensions: 20 x 16.5 mm

- Weight: 2.4 g (both together)

Included:

- 2 x board with Hall sensors

- 2 x impeller with magnets

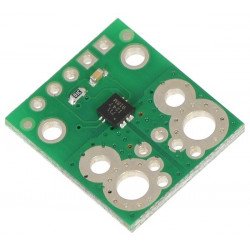

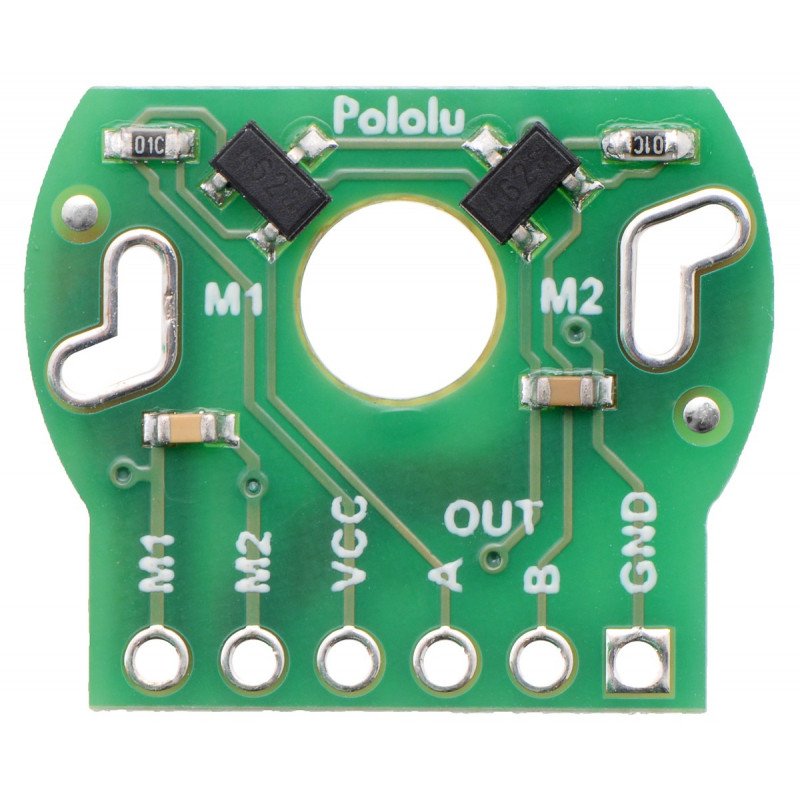

The size of the main board.

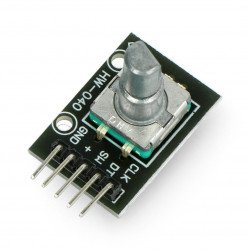

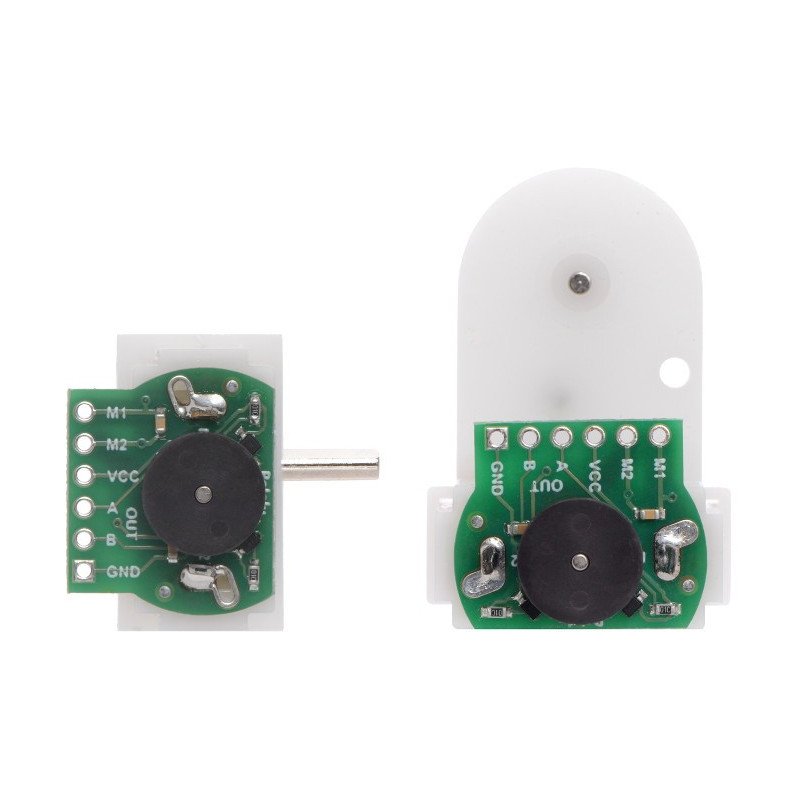

Installation and connection

The board with sensors are designed for direct soldering on the power pins at the rear of the engine. The corresponding alignment of the module is the key to receiving the output signal of the high quality. One of the ways of the board installation, is to solder one end, then the align the module and solder the second pin. It is necessary to avoid prolonged heating of the pins of the engine as it may damage the plastic case.

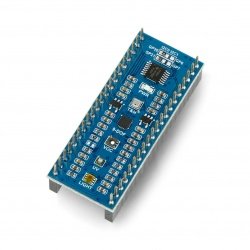

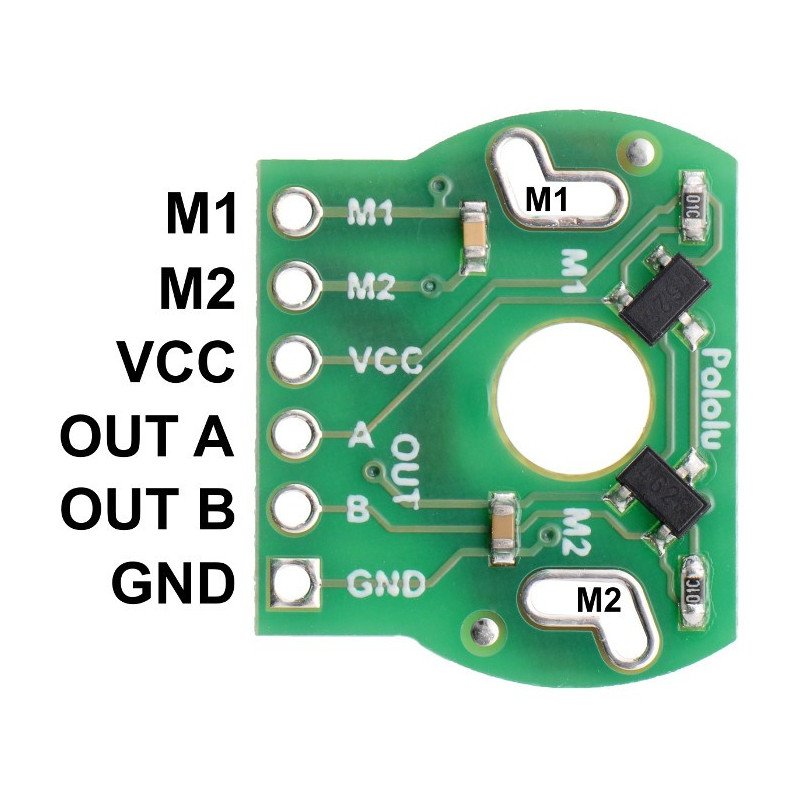

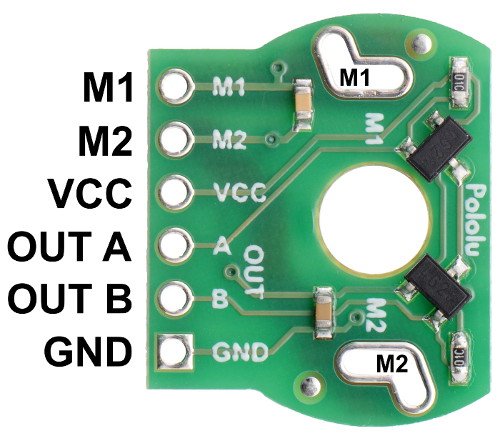

The distribution of the pins of the main board.

The distribution of the pins of the main board.

The mounting holes of the module are simultaneously power pins of the motor, connected to the M1 and M2 pins. OUTA, OUTB pins are the quadrature outputs. Sensor's power supply must be connected between pins VCC and GND. Pins are applied to the board that have a distance of 2.54 mm which provides the connection with, e.g. a breadboard.

When the module is properly soldered, on an extended shaft must be applied the impeller with magnets. The distance between the board and the impeller, doesn't affect the signal quality.

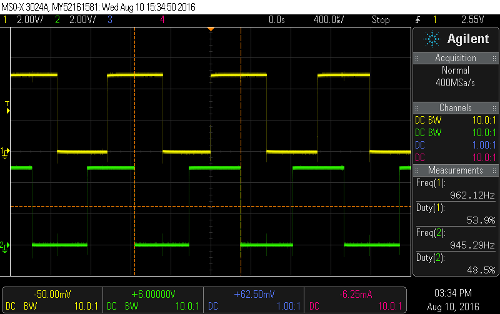

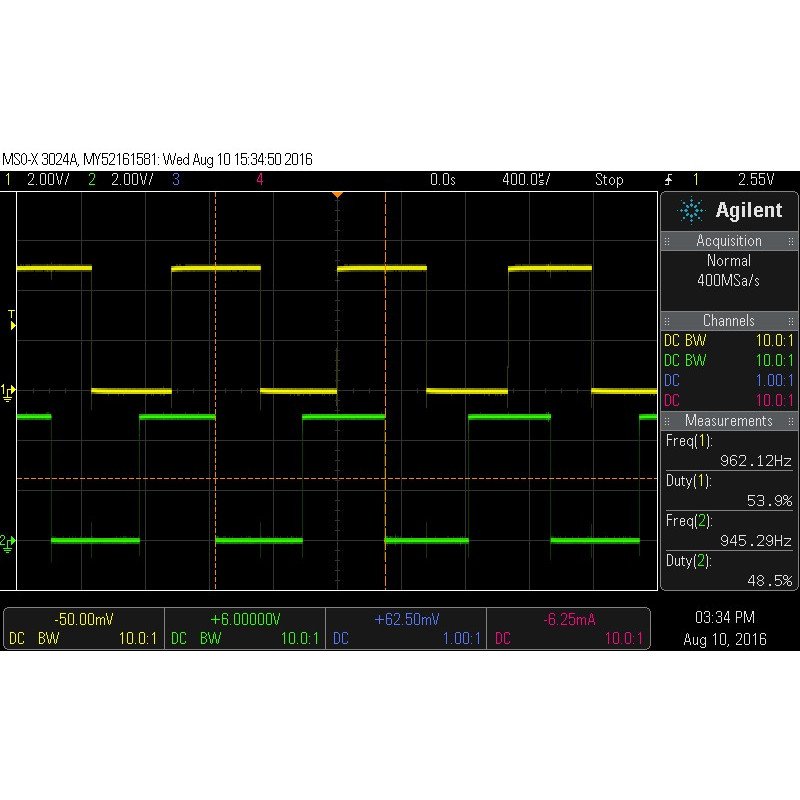

Oscillogram of the signal from the encoders.

Useful links |