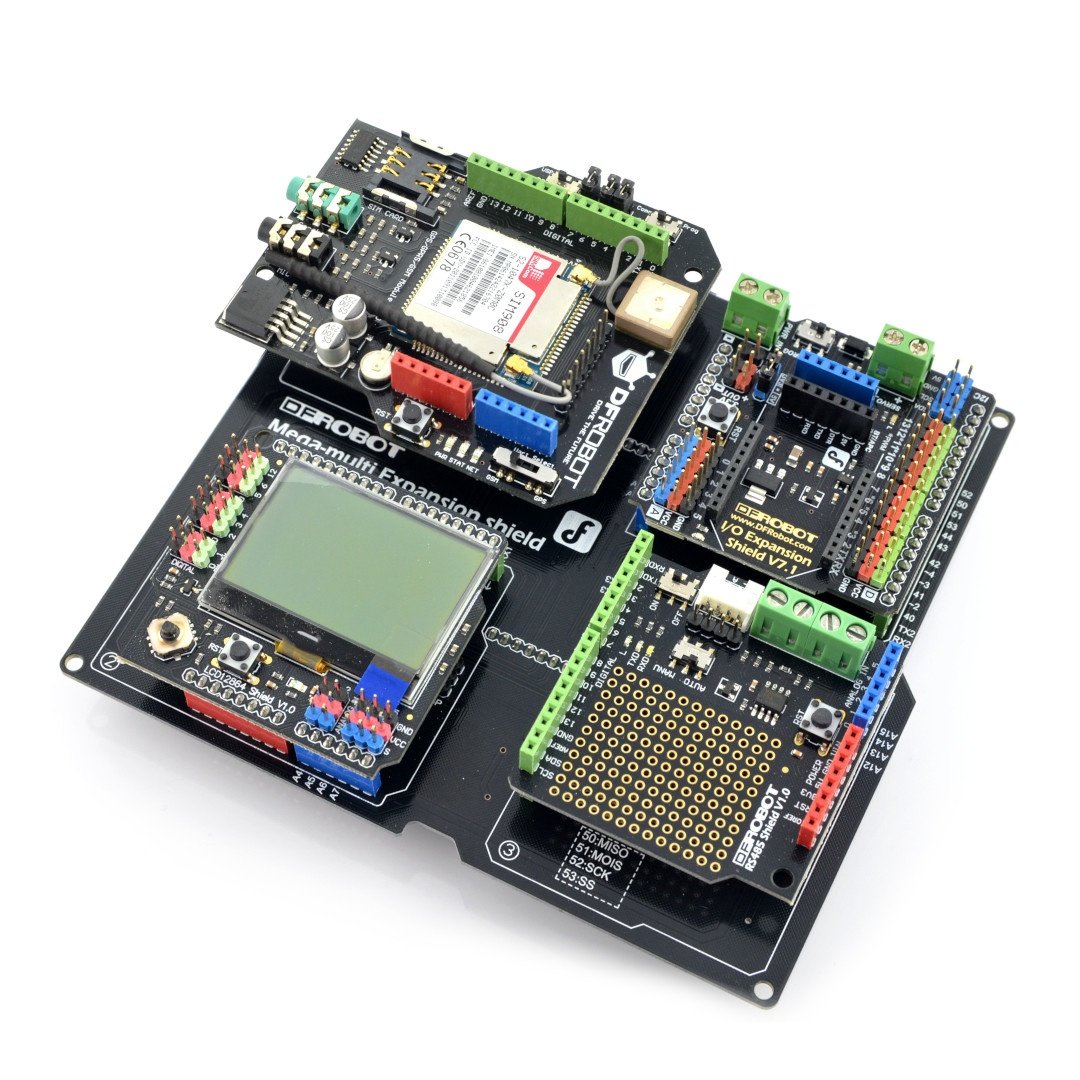

All constructions need a framework in order to remain stable, and this is the case with electronic devices, or more precisely with printed circuit boards. The purpose of this board is to maintain mechanical stability as well as to ensure proper, rigid electrical connections between the components. However, the board can only be created when the electronic circuit design is applied to the copper laminate. In the next stage it is chemically treated. We offer a wide range of laminates. They differ in size as well as thickness. They are available in single- and double-sided versions. You can buy laminates individually or in a set, depending on your needs and project size. In addition, we have prepared an offer of accessories, i.e. pickling tanks, laminate cutters and laminate polishing cleaners. An interesting proposal is laminate with extra photosensitive coating. Check our offer and create a stable framework for your electronic device.

Laminaty PCB

- Relevance

- New products first

- Name, A to Z

- Name, Z to A

- Price, low to high

- Price, high to low

- In stock

- Random

- 12

- 24

- 60

Laminate FR4 double-sided size L

FR4 double sided laminate with a thickness of about 1,5 mm. Copper layer 35 um. Sheet dimensions are 130 x 200 mm, with a tolerance of up to 20 mm.Laminate set FR4 0,35kg - 15pcs.

The set includes about 15 FR4 single and double-sided laminate tiles of different sizes. The total weight is 0.35 kg. The copper layer is 35 μm thick.Laminate FR4 double-sided M size

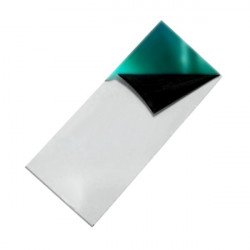

FR4 double sided laminate with a thickness of about 1,5 mm. Copper layer 35 um. Sheet dimensions are 90x 200 mm, with a tolerance of 20 mm.Light sensitive positive laminate double-sided 10x15 cm

Glass-and-Epoxy photosensitive laminate. Plate measuring 10 x 15 cm with a layer of copper and a photosensitive coating applied to it. Enables independent making of printed...Photosensitive laminate single-sided 15x20cm

Glass-and-Epoxy photosensitive laminate. Plate measuring 15 x 20 cm with a layer of copper and a photosensitive coating applied to it. Enables independent making of printed...FR4 single-sided laminate - 13,5x20cm

Single-sided laminate measuring 13.5 x 20 cm and 1.6 mm thick is an excellent material for creating your own printed circuit boards (PCB). Made of high-quality epoxy-glass...Laminate FR4 one-sided size XL

FR4 laminate on one side with a thickness of about 1.6 mm. Copper layer 35 um. The sheet dimensions are 170 x 250 mm, with a tolerance of 20 mm.See also

PCB laminate - the skeleton of an electronic device

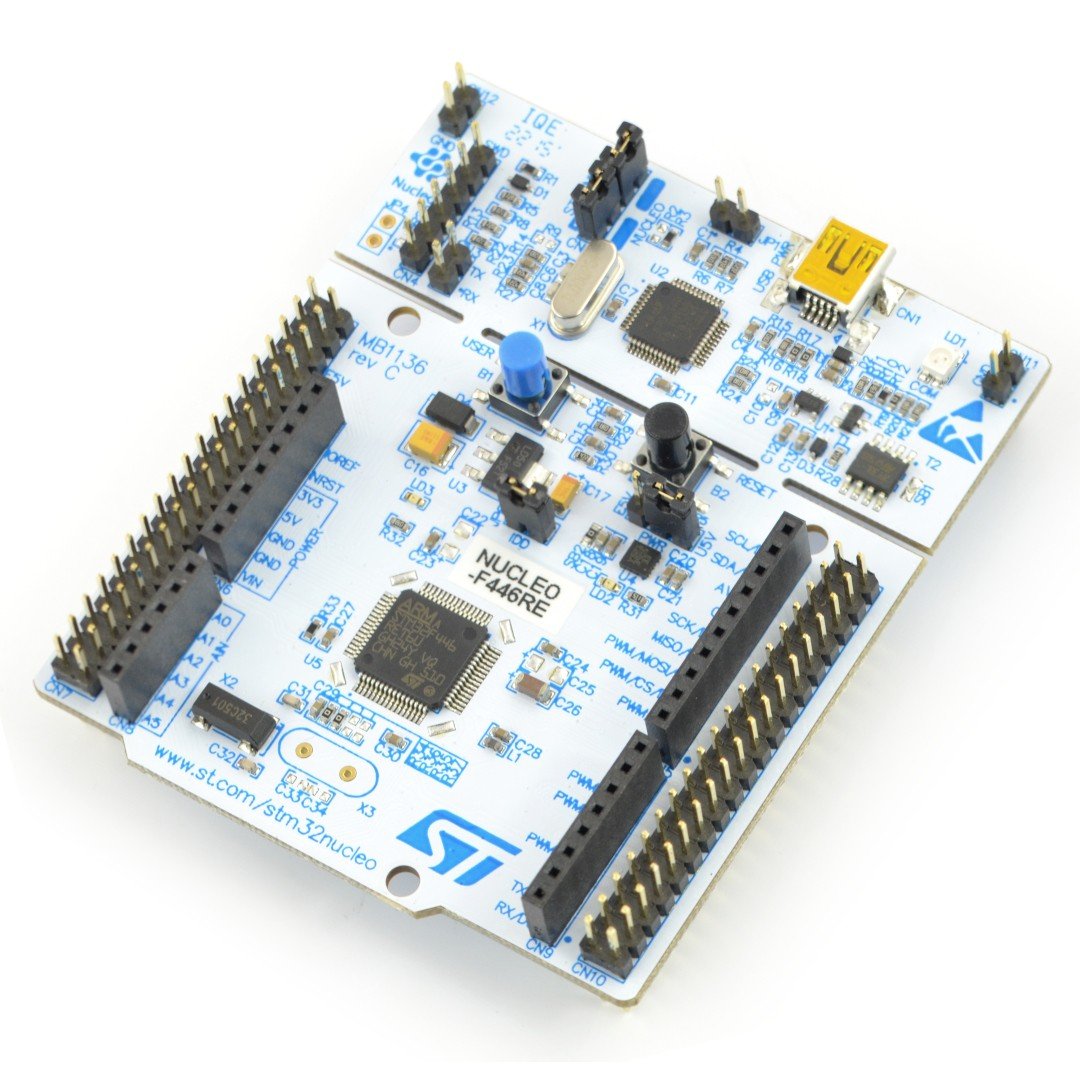

PCBs most often take the form of specially etched copper tracks arranged in a rectangular shape. The copper layer is often covered with a solder mask, which significantly facilitates the soldering process while minimizing the risk of unwanted solder spilling on the PCB surface. There are many types of laminates, but their parameters should be taken into account already at the stage of developing the device design, because even the most optimally designed system made of the most carefully selected electronic components may be damaged due to the use of an inappropriate laminate. Damage to the laminate may occur even during the assembly of the device. The most common type of laminate used in the production of PCBs is the FR4 type - it is a glass-epoxy laminate with a 35 μm thick copper layer. This laminate is available in the Botland store with a total thickness of 1.0 mm to 1.6 mm - its affordable price and very good mechanical, thermal and electrical properties are the main reasons why it can be successfully used in electronic devices for various applications and energy parameters.

Useful accessories for laminating and laminate processing in an electronics workshop

The Botland store also offers light-sensitive laminates , which enable the production of PCBs using an alternative method to thermal transfer. If you want to protect important paper documents against damage or dirt, a laminator will be a helpful tool for you. To precisely match the laminate surface to the design of your printed circuit board, use special scissors and then a cleaner that will easily remove unwanted dirt from the laminate surface. In this way, you can start etching the board, which will constitute the skeleton of the electronics in your device - a very good solution here is to use an electric etching machine with the possibility of setting the parameters of the etching process, thanks to which you will obtain high quality printed paths.

Laminates - FAQ

PCB laminates are the base materials from which PCB boards are created. Most often, you can buy them in the form of larger sheets or already cut to the appropriate dimensions.

The most popular are composite laminates (CEM1, CEM3), phenolic-paper (FR-2, FR-3), glass-epoxy (FR-4) and glass-Teflon (PTFE). The material of manufacture determines, among other things, the hardness of the tile and its resistance to temperature and the effects of various substances.