- Page

- View all

- Minicomputers

- 3D print

- Electronics

- Sensors

- Robots & mechanics

- Tools & Power

- Education

- Smart Home

- Others

- MINICOMPUTERS

- View all

- Arduino

- Raspberry Pi

- Nvidia

- Flipper Zero

- Other minicomputers

- Odroid

- BBC micro:bit

- PLC drivers

- M5Stack

- 3D PRINTING

- View all

- 3D printers

- 3D printers - resin

- 3D scanners

- Laser plotters

- Laser cutting machines - engravers, plotters

- Laser heads

- CNC milling machines

- Filaments

- Accessories for 3D printers

- Components for 3D printers construction

- Resins for 3D printers

- Accessories for CNC

- ELECTRONICS

- View all

- Computer accessories

- Automobile accessories

- Cooling

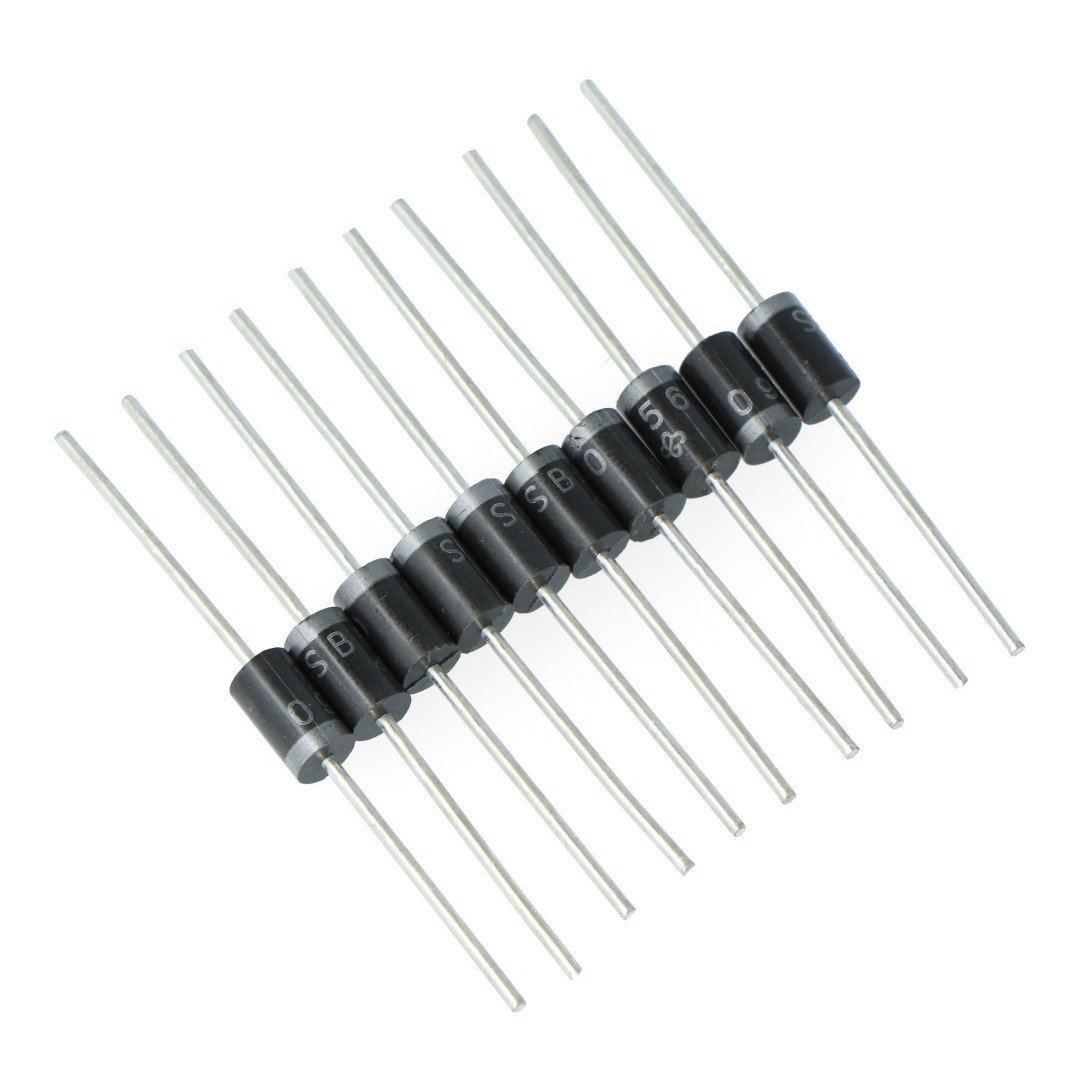

- Diodes

- Sound and acoustics

- Mounting components

- Passive elements

- Wearables (e-textiles, smart clothes)

- Cameras and recorders

- Consoles

- Memory cards & disks

- Communication

- Converters

- Electronics courses

- Microcontrollers

- Animal repellers

- LED lighting

- Programmers

- Relays

- Voltage regulators

- Artificial intelligence

- Motor drivers and servos

- Integrated circuits

- Displays and screens

- Tablets and smartphones

- More...

- SENSORS

- View all

- Accelerometers

- Alarm sensors

- 9DoF IMU sensors

- Pressure sensors

- Air quality sensors

- Sound sensors

- Gesture sensors

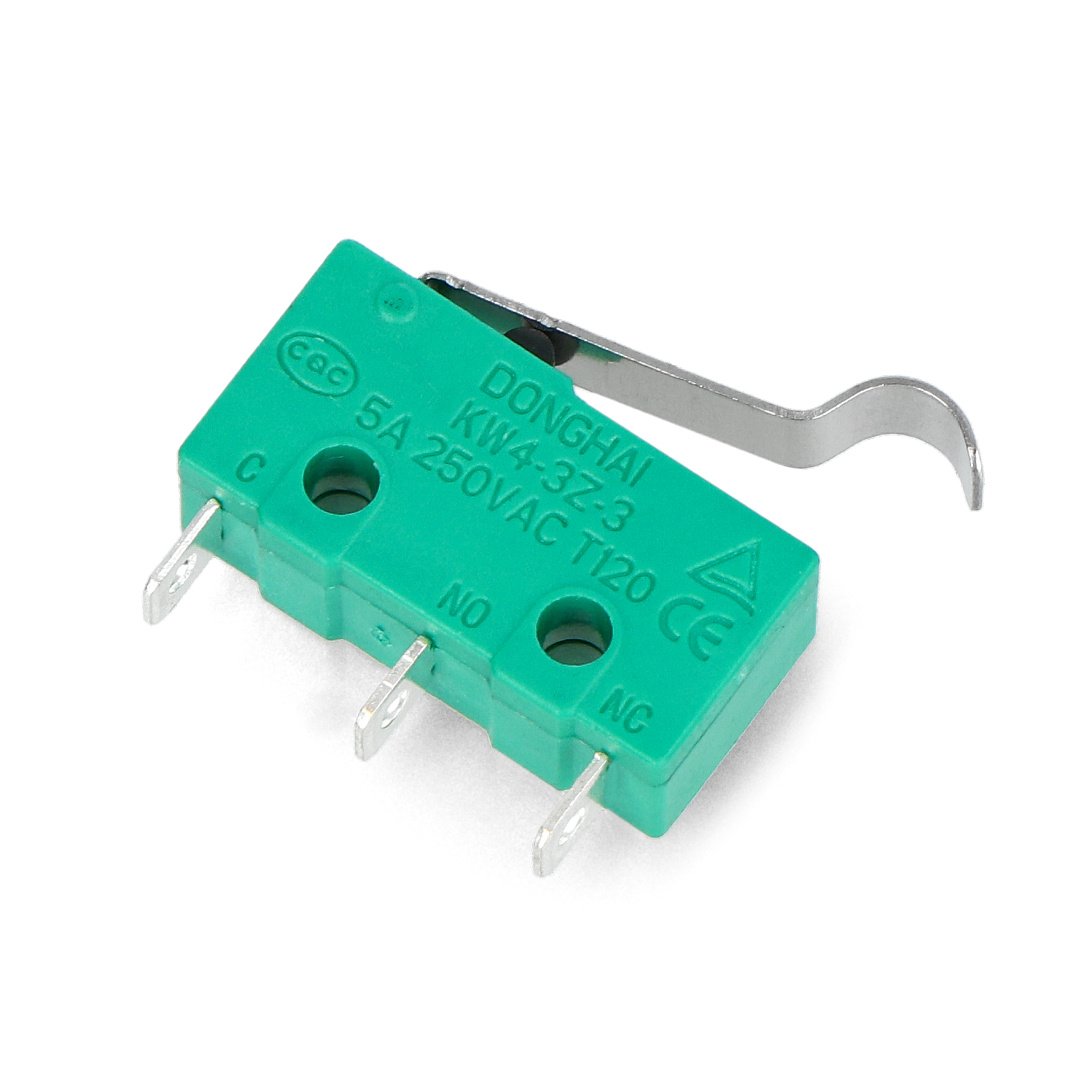

- Limit switches

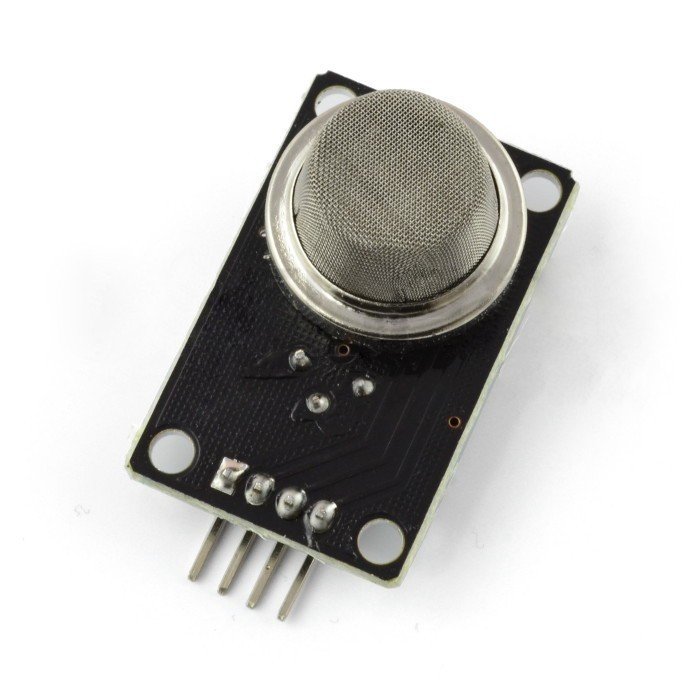

- Gas sensors

- Grove modules

- Gravity modules

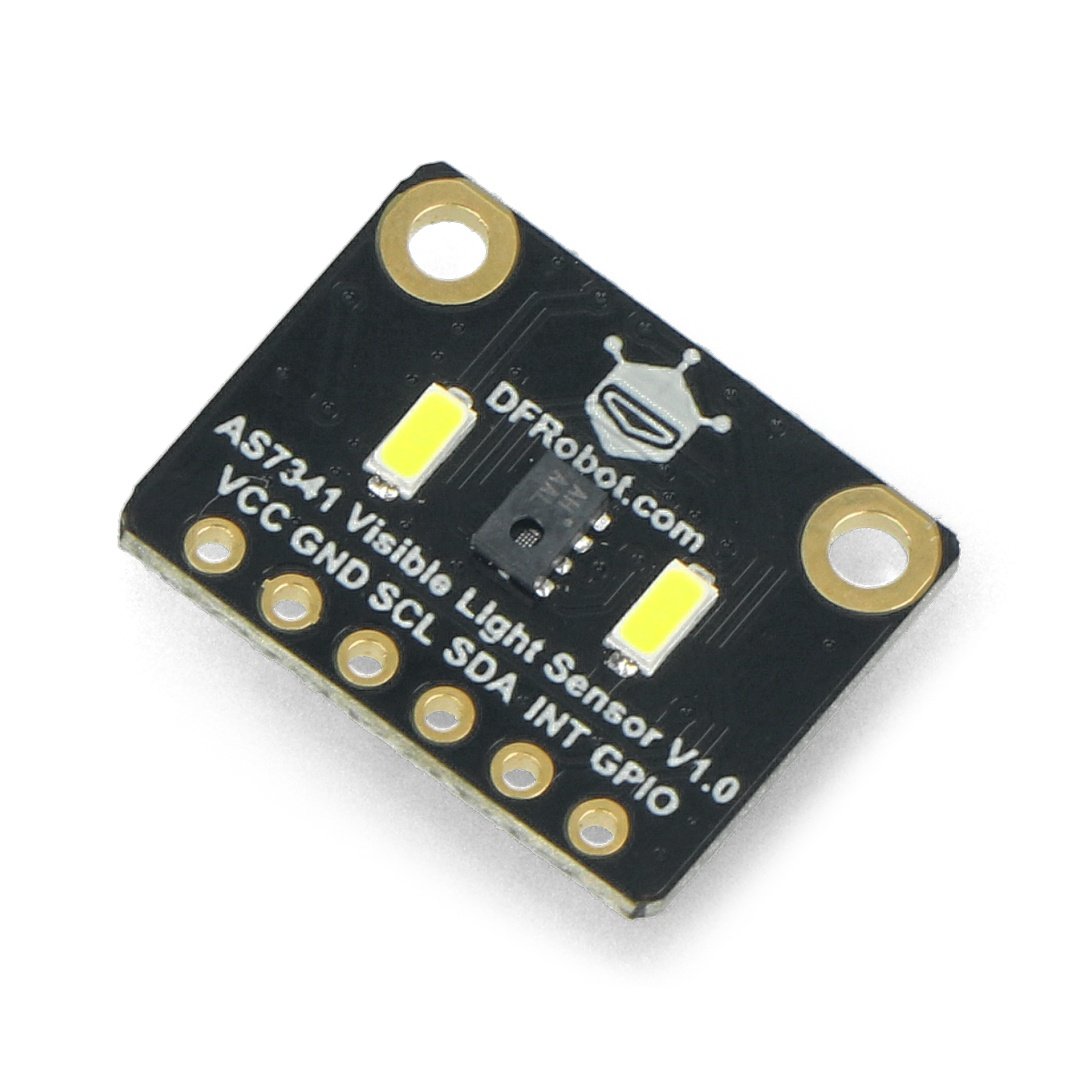

- Sensors of light and color

- Magnetic sensors

- Medical sensors

- Pressure sensors

- Sensors odbiciowe

- Distance sensors

- Inductive contactless sensors

- Weather sensors

- Liquid level sensors

- Current sensors

- Flow sensors

- Motion sensors

- Temperature sensors

- PT100 temperature probes

- Humidity sensors

- Fingerprint readers

- Encoders

- Photoresistors

- Phototransistors

- IR receivers

- Magnetometers

- Gyros

- Sensor sets

- Door sensors

- Hall effect sensors

- RPM sensors

- Optical sensors

- Tilt sensors

- Resistance sensors

- Inductive sensors

- Piezoelectric sensors

- Oxygen sensors

- Twilight sensors

- More...

- ROBOTS AND MECHANICS

- View all

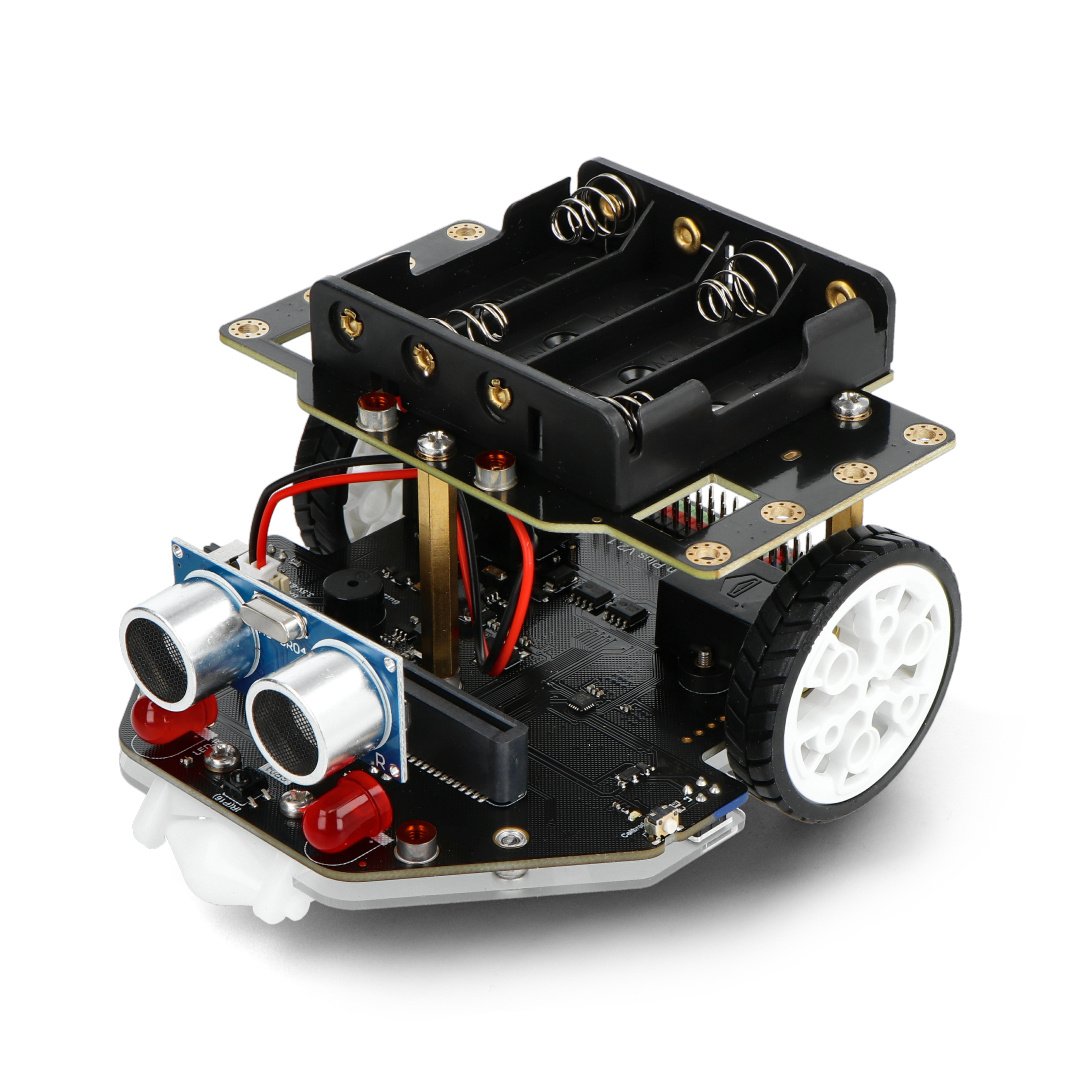

- Robots

- Servos

- Motors

- Mounting components

- Wheels

- Gimbals

- RC drones & cars

- TOOLS AND POWER

- View all

- Tools

- Chemistry

- Soldering

- Power supply

- Measuring instruments & devices

- Optical equipment

New products

- New

- New

Promotion products

- On sale!

- Promotion

Q-T-B soldering tip for Quick soldering stations - 960-B series

- Reduced price

- Promotion

- Reduced price

- Promotion

HiFiBerry DAC+ ADC Pro - sound card for Raspberry Pi 4B/3B+/3B

- Reduced price

- Promotion

- On sale!

- Promotion

Zamrażacze w sprayu do elektroniki

Cooling preparation - Freeze -55 st. C - 300ml

Cooling preparation for finding faults by thermal method, e.g. cold solder, microcracks, etc. The capacity of the package is 300 ml.See also

Metal spray freezer - an electronic accessory

The metal spray freezer is one of the products that should be found in every electronic workshop. It has many applications - it can be used, among others, to locate damaged electronic components, find micro-cracks in printed circuit boards and detect so-called cold solder connections, i.e. incorrectly made soldering connections. The freezer can also be used when testing electronic components whose operation depends on the temperature they currently have (for example, temperature sensors, thermistors or varistors), checking the proper functioning of devices designed for use in extreme temperatures, thermal extrusion of sleeves or pins, thermal type fault detection (for example, problems occurring after heating or cooling the system) and assisting in dismantling seals and other rubber components.

Detection of cold solder and other faults using the freezer

Electronics use a metal spray freezer to detect, among other things, faults, damage and malfunctions in electronic devices. One of the most popular applications is to locate so-called cold solder, i.e. incorrectly made soldering connections. Cold solder is formed when the binder is melted by the soldering iron itself, and not by heating the combined metals to high temperature. Then a visually similar connection to the correct one is obtained, but with much worse conductivity, weaker tightness and lower mechanical and thermal resistance. Cold solders can be detected by spraying a freezer on the soldering connections and observing changes in their operation and appearance - a properly made connection should only cover with frost and continue to function properly. Cold solders, on the other hand, can shrink and crack, as well as easily detach, and their functioning will be significantly impaired (they can also stop working at all). In a similar way, faulty ICs can also be detected, as can other faults, such as problems caused by temperature fluctuations (such as drops in performance or suddenly switching off devices).

Other spray freezer applications

The freezer is also ideal for testing electronic components and temperature-dependent devices. It can be used to check the operation of temperature sensors, thermistors or varistors as well as thermostats or weather stations. It is also an excellent tool for removing certain contaminants, such as chewing gum or adhesive residues stuck to a fabric or other rough surface. The freezer can also be useful when removing old, corroded rubber or soft plastic coatings. Among other things, you will find the Freeze Spray Freezer in our offer. The product is available in 300 ml cans, which is sufficient for a long life. The product can cool the surface even to -55°C, which makes it suitable for any of the above mentioned applications.

Precautions when using freezers

Take appropriate precautions when using spray-freezers. Do not spray the spray on objects other than those indicated for use, in particular flammable surfaces, hot components and sources of sparking and open flames (this also applies to heavily heated parts in electronic devices). Do not inhale the gas or direct it towards the eyes or skin - this can cause irritation and frostbite or even damage to the cornea. Preparations of this kind should be stored in a shady place of constant temperature, out of reach of children.

preview

preview

preview

preview

preview

preview

preview

preview

preview

preview

preview

preview

preview

preview

preview

preview

preview

preview

preview

preview

preview

preview

preview

preview

preview

preview

preview

preview

preview

preview

preview

preview

preview

preview

preview

preview