Prusa is one of the most recognized companies in the 3D industry. Their first 3D printer was released in 2010, and after showing two other models, the group started to focus on improving their best selling Prusa i3. This is how a whole new line called “MK” emerged and became greatly popular around the world. Czech manufacturer, Prusa Research, produces both printers that use fused deposition modeling (FDM) with multi-material printing and stereolithography (SLA) machines. The business founder Josef Prusa constantly improves the open-source ecosystem he created. Both hardware and software are regularly updated thanks to great contact with the users’ community. The Czech manufacturer is one of the fastest-growing tech companies in Central Europe, with a growth rate of 17,118% over the last four years. In Botland.store, we offer a wide selection of Prusa printers, parts, and accessories to help you achieve your 3D printing goals. Check our special bundles and safe-assembly sets and enjoy competitive prices.

3D printer - Original Prusa XL - 5 heads - assembled

Original Prusa XL is an advanced CoreXY 3D printer offering a 360 x 360 x 360 mm build volume that enables multi-material printing using five heads . It is equipped with a...3D printer - Original Prusa XL - 2 heads - assembled

Original Prusa XL is a modern 3D printer based on the CoreXY architecture, offering a build volume of 360 x 360 x 360 mm . It has two heads and supports multi-material...3D printer - Original Prusa MK4S Enclosure Bundle - for self-assembly

The Original Prusa MK4S Enclosure Bundle is an advanced DIY 3D printer with a 250 x 210 x 220 mm build volume and an included enclosure . Equipped with 360° cooling, a...3D Printer - Original Prusa SL1S SPEED - assembled

Original Prusa SL1S 3D printer working with MSLA technology. It uses a high-resolution 5.96" monochrome LCD screen and a UV LED panel for curing thin resin layers. The...3D printer - Original Prusa MK4S - assembled

3D printer from the Czech company Prusa, known among 3D printing enthusiasts. The device is based on a 32-bit motherboard and supports Input Shaper and Pressure Advance...3D printer - Original Prusa MK4S - set for self-assembly

3D printer from the Czech company Prusa, known among 3D printing enthusiasts. The device is based on a 32-bit motherboard and supports Input Shaper and Pressure Advance...3D printer - Original Prusa CORE One+ - assembled

The Prusa CORE One+ is a fully assembled CoreXY 3D printer offering high print quality, speed, and reliability. Equipped with a closed, heated chamber , a steel...3D Printer - Original Prusa CORE One+ - self-assembly kit

The Prusa CORE One+ is a closed CoreXY 3D printer combining high printing precision, speed, and reliability. Equipped with a steel exoskeleton , a modern Nextruder...3D printer - Original Prusa XL - 1 head - assembled

Original Prusa XL is an advanced CoreXY 3D printer with a large build volume of 360 x 360 x 360 mm . It has a single head and offers optional support for five...3D printer - Original Prusa XL - 1 head - Enclosure Bundle - assembled

Original Prusa XL with official housing is an advanced 3D printer in the CoreXY system, offering a build volume of 360 x 360 x 360 mm and delivered assembled . Standard...3D printer - Original Prusa XL - 2 heads - Enclosure Bundle - assembled

Original Prusa XL with enclosure is an advanced CoreXY 3D printer, offering a build volume of 360 x 360 x 360 mm . It has two heads and the ability to print...3D Printer - Original Prusa MINI+ - set for self-assembly

3D printer, which is manufactured by Prusa. It uses a 32-bit motherboard with silent Trinamic 2209 stepper motor drivers and an Ethernet communication interface. The working...- Discontinued product

3D Printer - Original Prusa MINI+ - kit for simplified assembly

Original 3D printer by a renowned manufacturer, Prusa. The device uses FFF/FDM incremental technology. In Prusa MINI+ a modern 32-bit motherboard with Trinamic 2209...- Discontinued product

3D printer - Original Prusa MK4S Enclosure Bundle - assembled

The Original Prusa MK4S Enclosure Bundle – a pre-assembled 3D printer – is a complete, ready-to-go solution for hobbyists and professionals. The printer offers a build...3D printer - Original Prusa XL - 1 head - self assembly kit

Original Prusa XL is an advanced CoreXY 3D printer with a build volume of 360 x 360 x 360 mm . It has a single head, but allows multi-material printing thanks to an...- Discontinued product

3D printer - Original Prusa XL - 5 heads - self-assembly kit

Original Prusa XL is an advanced CoreXY 3D printer with a build volume of 360 x 360 x 360 mm , enabling multi-material printing using five heads . Equipped with...- Discontinued product

3D printer - Original Prusa XL - 2 heads - self assembly kit

Original Prusa XL is an advanced CoreXY 3D printer with a build volume of 360 x 360 x 360 mm . It has two heads and the ability to print multi-materials thanks to a system...- Discontinued product

3D printer - Original Prusa XL - 2 heads - Enclosure Bundle - self-assembly kit

Original Prusa XL with case is an advanced, partially assembled CoreXY 3D printer, offering a build volume of 360 x 360 x 360 mm . It has two heads and the ability to...- Discontinued product

3D printer - Original Prusa XL - 5 heads - Enclosure Bundle - self-assembly kit

Original Prusa XL with official case is an advanced CoreXY architecture 3D printer, delivered partially assembled . It offers a 360 x 360 x 360 mm build volume and...- Discontinued product

3D printer - Original Prusa XL - 5 heads - Enclosure Bundle - assembled

Original Prusa XL with a dedicated enclosure is an advanced 3D printer based on the CoreXY architecture, available in a factory-assembled version. It offers a workspace of...See also

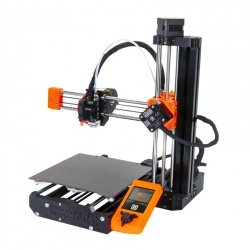

Classic Prusa i3 MK3S 3D printer

The i3 series models are already classics of the Czech brand. They are available in two variants: for self-assembly and in an assembled version, ready for work. The currently offered Prusa i3 MK3S 3D printer provides its users with a working space of 250 x 210 x 210 mm. The device can work with a wide range of filaments - from the obvious ones such as PLA, ABS, HIPS or PET, to T-Glase, Nylon or Bamboofill (with bamboo fibers). The many amenities and innovations of the i3 MK3S model include the modernized Bondtech extruder with gears ensuring double-sided hold of the filament, or an optical sensor with a mechanical lever that guarantees effective operation even in the case of transparent materials. The PINDA 2 proximity sensor installed in this Prusa 3D printer model supports the precise, automatic auto-leveling procedure of the worktable. An additional advantage of the device is increased printing speed (above 200 mm/s) and much quieter operation of the device (thanks to Trinamic 2130 drivers). The Multi Material 2S (MMU2S) kit is available for the i3 MK3S model - an overlay that allows printing with up to five filaments using one nozzle.

Prusa MINI+ 3D printer - for small but precise details

The working area of the Prusa MINI 3D printer in the "plus" version has dimensions of 180 x 180 x 180 mm. The device is delivered in the form of a self-assembly kit, which can be easily installed even by non-advanced users. The small dimensions of the device were achieved thanks to its original design - instead of a rectangular frame adjacent to the printer base on both sides, we have the Z axis located only on one side. The arm with the print head moves on three guides, and is additionally lightened - the extruder motor is mounted on the Z axis, not on the movable arm. Obtaining high-quality prints is supported by the option of automatic leveling of the work table, carried out on the basis of grid line analysis and implemented by the SuperPinda sensor, which is resistant to temperature differences. The Prusa MINI+ 3D printer also brings innovative parameters of the motherboard - Buddy, as it was named, has a 32-bit architecture and is additionally equipped with Trinamic 2209 drivers, which reduce the noise emitted during printing and increase the efficiency of the process.

Prusa 3D for UV resin printing

The Prusa 3D printers offer also includes devices based on light-cured resin. The original Prusa SL1 provides the user with a working space of 120 x 68 x 150 mm and uses MSLA technology. The material is hardened by a 5.5-inch LCD panel and UV LED lamps. The screen resolution reaches 2560 x 1440 pixels, thanks to which each layer of the print is reproduced in the smallest detail, and the final effect is impressive in quality. Working on a single print layer takes 6 seconds. The solutions used in the tank are worth noting: the resin level sensor protects against uncontrolled interruptions in work, the FEP foil seals the container, and the ability to change the angle of the tank facilitates the creation of models with a large cross-sectional area. It is possible to purchase a Prusa 3D printer with an original Prusa CW1 washer, responsible for hardening, cleaning and drying finished models.

Josef Prus's first 3D printer hit the market in 2012. The Czech international brand offers both 3D printers using the FFF/FDM printing method and the SLA method (hardening of very thin layers of resin using ultraviolet light). In addition, the Prusa range includes a wide selection of accessories, kits extending the capabilities of 3D printers and spare parts. Prusa 3D printers are compatible with most 3D printer filaments and resins available on the market.

The Prusa i3 MK3S+ 3D printer deserves special attention, which is available in both a pre-installed and self-assembly variant. The device is characterized by easy operation, precise and fast printing, and a clear LCD display. People looking for a 3D printer using SLA technology should check out the Prusa SL1S SPEED model, which allows the use of resins from external manufacturers. The device allows you to print elements with maximum dimensions of 127 mm x 80 mm x 150 mm.