Amateur robot builders are very keen on using an arsenal of components and materials originally intended for modelers.No wonder - the requirements of small robots in terms of weight and overall size limitations, as well as the forces and torques achieved, mean that automation enthusiasts can successfully use popular servo systems. For them, we have provided universal servo mounts that will make mounting your own structures much easier.

Servo holders and mounts

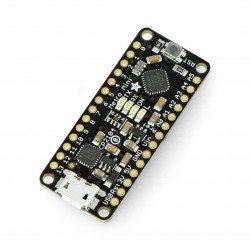

Micro Pan/Tilt Servo Bracket - SparkFun ROB-10335

Metal bracket enables creating platforms, controlled by servos. A kit for self-assembly allows to build, for example, rotating camera stand for face tracking.Aluminium Servo Mount Feetech FK-MB-001 - black

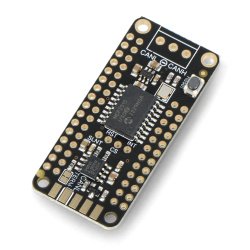

Aluminum servo mount in size 58 x 37 x 25 mm and weighing 15 g.Pan / Tilt standard servo mount

Metal mount enables creating platforms, controlled by servos. A kit for self-assembly allows you to build, for example, a rotating camera stand for face tracking. The kit...Standard Servo Mount - Pololu 3435

Plastic mount for standard servos, provides a convenient mount for servos on a flat surface. Mount in black.Micro Gripper Kit - gripper with micro servo - Pololu 3551

A kit for making a mini gripper with a maximum distance of 32 mm. Set also includes a micro servo that was specially modified with an extra wire, providing access to the...See also

Pan/tilt handles

The servo mounts available in our offer facilitate the construction of high-quality mechanisms, allowing to control (in two axes) the position of various elements, such as cameras, range finders or other sensors and effectors. This type of design - commonly called pan/tilt - actually forms what is known as a serial kinematic chain. This means that each successive segment - a "chain link" - uses the previous element as its base. In this way, the resultant motion of the last link and its connected component consists of the motions of the drives, located between all the other links. The simplest version of such a mechanism can use only two drives - one servo is responsible for rotation of the whole in the vertical axis (right-left), and the second - for rotation in the horizontal axis (up-down).This is how, for example, Dagu servo mounts work, adapted for use with standard and micro servos.

Examples of pan/tilt applications

One of the most interesting and impressive uses of this type of mechanism is a robot that tracks faces with a camera. You can use a Raspberry Pi minicomputer with a camera module and a hat overlay to control the servos and, of course, the appropriate servo mounts. In simpler applications, the camera can simply track a moving object or, for example, only objects of a given color. The pan/tilt system can also be used for building one's own system for remote monitoring of an apartment, room, studio or, for example, for viewing the work of a 3D printer. However, vision applications do not exhaust the list of potential applications of such mechanisms. Another interesting application is the construction of a simple robotic arm, ending in a gripper, also driven by servos (e.g. Pololu Micro Gripper Kit). Such an arm would use aluminum servo mounts as structural elements.

Other Servo Mounts

There's nothing stopping you from trying to combine the two pan/tilt mechanisms into a larger chain - just be sure to keep the weight of the whole thing low, as the lowest servos (i.e. those drives that work closest to the base of the robot) are loaded with the total weight of the further arms (and possible effector). For more sophisticated designs, where the only limitation is the imagination of the designer and the torque of the servos used, various types of more or less complex servo mounts, such as FK-LS-001 or FK-MB-001 will be suitable.