Product description: Dimafix printing glue - 400 ml spray

A product thatimproves the adhesion of3D prints to the glass surface of the printing table. Designed for printers using FFF/FDM technology. Dimafix significantly facilitates work with almost all thermoplastic materials. Its use is recommended especially when working with high shrinkage filaments,more exposed to undesirable warping. The effect of Dimafix depends on the temperature of the surface on which it is applied. Its adhesive properties become active when it exceeds 50°C. They disappear when the temperature is reduced to between 40°Cand50°C. The product is sprayed in a400 mlcan with a ball to prevent nozzle clogging. It ensures easy even spraying on the hotbed surface. One pack is sufficient for approx. 100 applications.

Video showing how to use Dimafix.

Four action zones

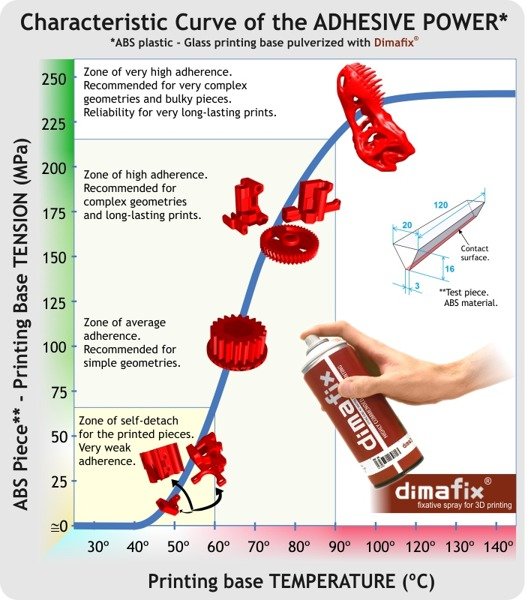

Dimafix protects againstunwanted tearing of the model from theprintingtable, even for the most demanding filaments. It can be used withABS, PVA, Filaflex,Polyprylene, HIPS, among others. Adhesive properties of the product vary depending on temperature. On the example of ABS thermoplastic we can distinguish four thermal ranges of Dimafix:

- Zone IV- temperaturefrom 95°C to 120°C.Maximum adhesion of the printed component, any size and shape. This range provides an improvement in printing quality of sharp edges and tops of the 3D model.

- Zone III- temperaturefrom 75°C to 95°C.Zone of high adhesion of the print. 3D model can have any shape and maximum size of 200 x 200 mm. Good print quality without curling even when print cooling is on.

- Zone II- temperaturefrom 65°C to 75°C. Averageadhesion power suitable for straight components without sharp edges.

- Zone I- Temperaturebelow 65°C.For easy exit of the printout from the table. If the table cools down, the printout should exit by itself.

Graph of temperature dependence of adhesion properties (for ABS).

Directions for use

- Shake the container before use

- The preparation should be applied at a distance of approx. 30 cm from the surface of the printer table. The manufacturer recommends to perform this operation in ventilated rooms.

- The hotbed on which Dimafix is applied should have a temperature of about 50°C

- Remains of the preparation from the surface can be removed with clean water

Dimafix printing glue - 400 ml spray.

|

In our offer there is also Dimafix Pen with 90 ml capacity. |

Useful links |