- Discontinued product

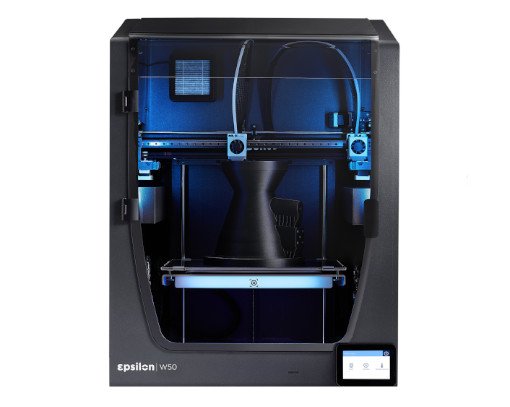

Product description: 3D printer - BCN3D Epsilon W50 SC - IDEX dual-extruder

BCN3D Epsilon W50 SC is a proposal that includes a professional Epsilon W50 3D printer and a special filament storage chamber. Smart Cabinet allows keeping the material for printing in conditions of appropriate humidity, thus maintaining the properties of thermoplastic fibers. Epsilon W50 is an industrial 3D printer with a system of two independent IDEX extruders (allows you to create models in mirror and duplication modes). The device uses filaments with a diameter of 2.85 mm . Built-in UPS allows you to continue working after the main power is lost.

A 3D printer for professional use

The BCN3D Epsilon W50 is a model designed mainly for industrial purposes. He will check in prototyping and production of small product batches using the most advanced materials. Independent IDEX extruders and a closed working chamber with a capacity of more than 50 l make the Epsilon W50 suitable for many industrial segments. The device has a large working area: 420 x 300 x 400 mm .

Industrial printing speed

The Epsilon W50 has an advanced IDEX system based on the operation of two extruders. It allows each of the two printheads to move in the X-axis completely independently of each other. They can work in duplicate or mirroring mode.

IDEX is a solution based on the use of two independent extruders in a 3D printer, which allow for simultaneous printing with two colors or different types of filaments . This allows more efficient use of the entire working space of the device. IDEX is also great for creating soluble props. Cleaning nozzles protect against dirt and color mixing.

Forming a 3D model in the BCN3D Epsilon W50 SC .

Double the productivity

As part of the IDEX system, the Epsilon W50 offers two very efficient modes: duplicate and mirror. They allow you to speed up printing ( simultaneous formation of two models ) and use different colors and materials :

- Duplicate mode : involves forming two identical models using both heads. The user gets double the efficiency compared to traditional models of 3D printers with one extruder.

- Mirror mode - printing two models simultaneously in a mirror image. Not only the molding time is shortened here, but also the design time itself

Bondtech extruders and filament end sensor

The BCN3D Epsilon W50 uses efficient Bondtech extruders . Thanks to the double drive , they ensure more efficient and stable feeding of the filmanent, regardless of its type. Additionally, Epsilon is equipped with a sensor that stops the operation of the device when it detects a lack of printing material.

Closed working chamber with HEPA filter

The Epsilon W50 has a closed working chamber with passive heating that ensures a constant temperature around the 3D print. This solution avoids warping and detachment of formed models. This is especially important in the case of advanced, more complicated to use filaments (including ABS, PETG, Nylon, PP, PP GF30, PAHT CF15).

HEPA and carbon filters are equipped with a consumption level control system. They protect the surroundings of the 3D printer's workplace from harmful particles and unpleasant odors.

Compatible filaments

BCN3D Epsilon W50 enables printing with the use of the following types of filament: PLA, ABS, PETG, TPU, Nylon, PVA, PP, PAHT CF15, PP, GF30. Original BCN3D filaments were developed by BASF and Mitsubishi Chemical. Thanks to the open material policy, it is also possible to use thermoplastics from other manufacturers .

BCN3D Smart Cabinet

Smart Cabinet is a solution designed to maximize the life of printing materials. It provides appropriate conditions for their storage, especially in terms of optimal humidity. The chamber contains silica gel to absorb moisture. After proper saturation and heating, it releases it outside the system in a way that is safe for the filament. The device can hold up to 8 small spools (from 0.75 kg to 1 kg) or 4 large spools (up to 2.5 kg).

Filament protection against loss of properties

Smart Cabinet integrates seamlessly with the 3D printer. The wheels mounted on the bottom facilitate the transport of the whole set. The chamber has an additional drawer for tools . The main task of Smart Cabinet is to protect thermoplastics against the negative effects of excessive humidity . It affects all types of materials, including the specialized ones: PVA, PA, TPU. Due to their high hygroscopicity, they lose their basic properties over time in improper storage conditions. 3D models can display imperfections such as a rough surface or inaccuracies visible in printed layers.

Circulation of the filament drying system .

Smart Cabinet specification

- The optimal solution for all types of filaments

- Low power consumption: 12 W (average value), 100 W (maximum value)

- The device can accommodate:

- 8 small spools (0.75 kg to 1 kg)

- or 4 large spools (up to 2.5 kg)

- The use of silica gel ensures the right level of filament moisture

- Built-in wheels for easy transport of the set

Specification of the 3D printer - BCN3D Epsilon W50

| Technical Specifications | |

|---|---|

| Printing method: | FFF |

| Working area: | 420 x 300 x 400 mm |

| Supported materials: | PLA, ABS, Nylon, PETG, TPU, PVA, Composites, PP, PA + (with Hotend X: PP GF30, PAHT CF15) |

| Filament Diameter: | 2.85 mm |

| Extruder: | IDEX - 2 independent extruders, E3D hotends |

| Number of extruders: | 2 |

| Layer resolution: | from 0.05 mm to 0.5 mm (non-standard profiles) |

| Nozzle temperature: | up to 300 ° C |

| Printing platform: | glass, heated |

| Table temperature: | 120 ° C |

| Calibration: | semi-automatic with calibration assistant |

| Printing Modes: | regular, Dual - IDEX duplication, mirror |

| Display type: | touch 5 " |

| Interface language: | Spanish, English, German, French, Italian, Japanese, Portuguese, Chinese |

| HEPA filter: | HEPA filter, activated carbon filter |

| Communication: | WiFi, Ethernet, SD card |

| Software: | BCN3D Stratos (included), compatible with Slic3r, Simplify3D |

| Supported file types: | .stl, .3mf, .obj, .amf |

| Firmware: | BCN3D Embedded Linux distribution, BCN3D Epsilon - Marlin |

| Operating Systems: | Windows, Mac, Linux |

| Sensors: | filament end sensor |

| Positioning accuracy X / Y / Z: | 1.25 µm / 1.25 µm / 1 µm |

| Type of working chamber: | closed, passively heated up to 60 ° C, pause function when opening the door |

| Nozzle diameters supported: | brass nozzle: 0.4mm (default) / 0.6mm / 0.8mm / 1.0mm, Hotend X: 0.6mm |

| Power consumption: | 840 Watts |

| Working environment temperature: | 15 ° C to 35 ° C |

| Dimensions: | 530 x 690 x 900 (with wires) |

| Mass: | 37 kg |

Useful links |