Product description: Royal Resin Crystal epoxy resin 5 kg - casting - colourless

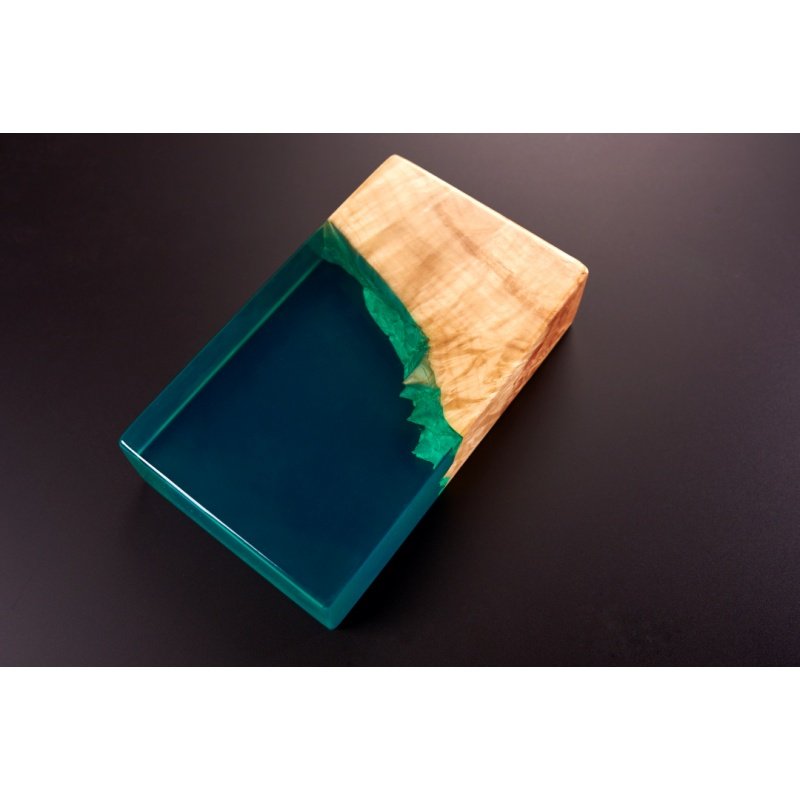

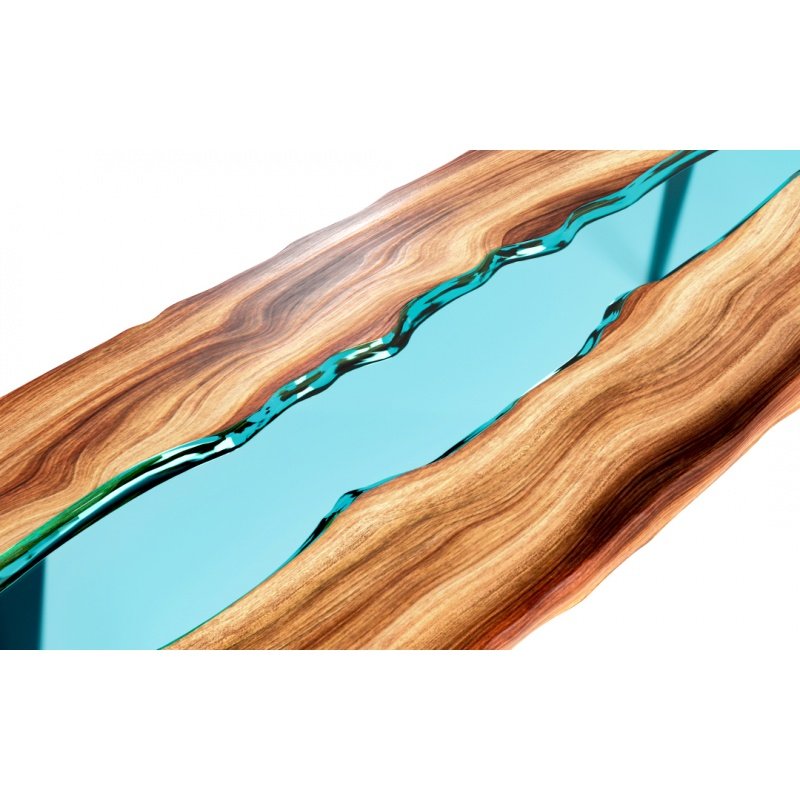

Clear, two componentepoxy resinmanufactured byRoyal Resin. Crystal clear and colourless, has ahigh gloss. The set consists of resin and hardener which should be mixed in ratio1:0,27. The material cures at room temperature within20 hours. Maximum cure is achieved after 72 hours. After hardening,waterproof,hardand strong material, resistant to UV radiation, is obtained. Epoxy resin is used in manufacturing and repairing processes. It has absolute adhesion to most surfaces. It can be used wherever it is necessary to coat,laminate, cast orprotectelements. The resin can be combined with additional components, such as epoxyresin dyes, to obtain any colour.

|

In our offer you can also find transparent and pearl pigments in different colours. |

Royal Resin Crystal's performance characteristics

- Used in production and repair processes

- Used for coating, laminating, casting, repairing and protecting items such as jewellery, 3D flooring, crafts and tabletops

- Resistant to most chemicals

- Resistant to UV light and yellowing

- Odourless, solvent free

- Electrostatic, self-leveling

- Low viscosity and minimal shrinkage

| Technical Specification | |

|---|---|

| Colour | Transparent |

| Mass | 5 kg |

| Shelf life of resin | 12 months from date of production |

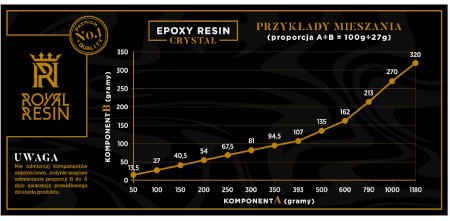

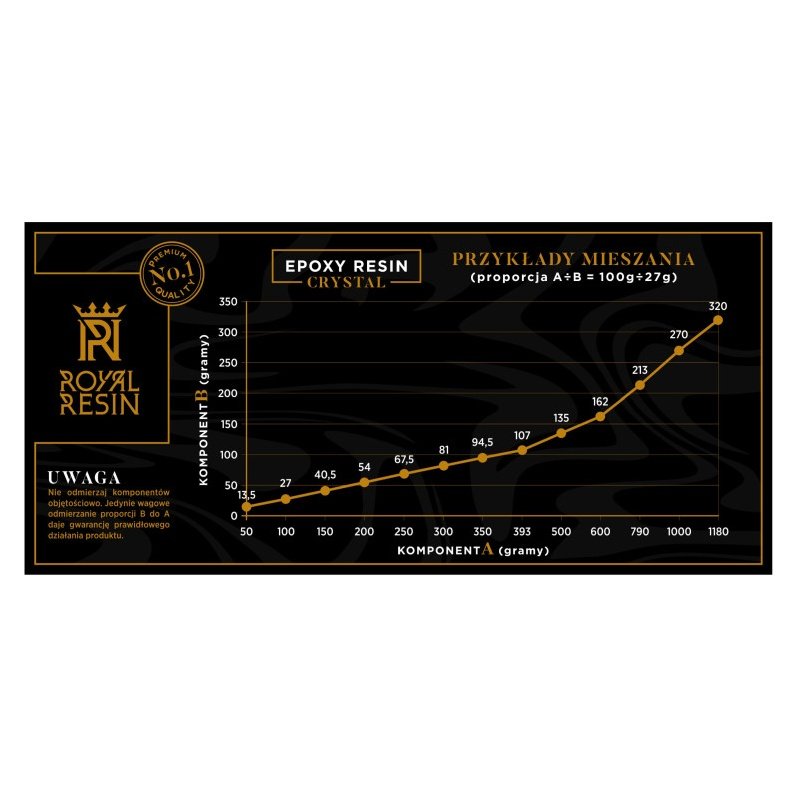

| Mixing ratio | 1:0.27 (e.g. 100 g resin : 27 g hardener) |

| Working time | 20 min. to 40 min. |

| Curing time | Up to 20 hours; fully cured after 72 hours |

| Shrinkage value | Minimum |

| Recommended thickness of a single layer | Up to 5 cm |

| Set contents |

|

Useful links |

Advantages

- Crystal clear and colourless with a high gloss finish

- Waterproof, hard, and strong material resistant to UV radiation

- Absolute adhesion to most surfaces

- Versatile use for coating, laminating, casting, repairing, and protecting items

- Resistant to most chemicals

- Odourless and solvent-free

- Electrostatic and self-leveling properties

- Low viscosity with minimal shrinkage

- Can be combined with dyes for custom colours

Disadvantages

- Requires precise mixing ratio (1:0.27) for optimal results

- Long curing time (up to 72 hours for maximum cure)

AI generated based on user reviews