Copper etchants

- Relevance

- New products first

- Name, A to Z

- Name, Z to A

- Price, low to high

- Price, high to low

- In stock

- Random

- 12

- 24

- 60

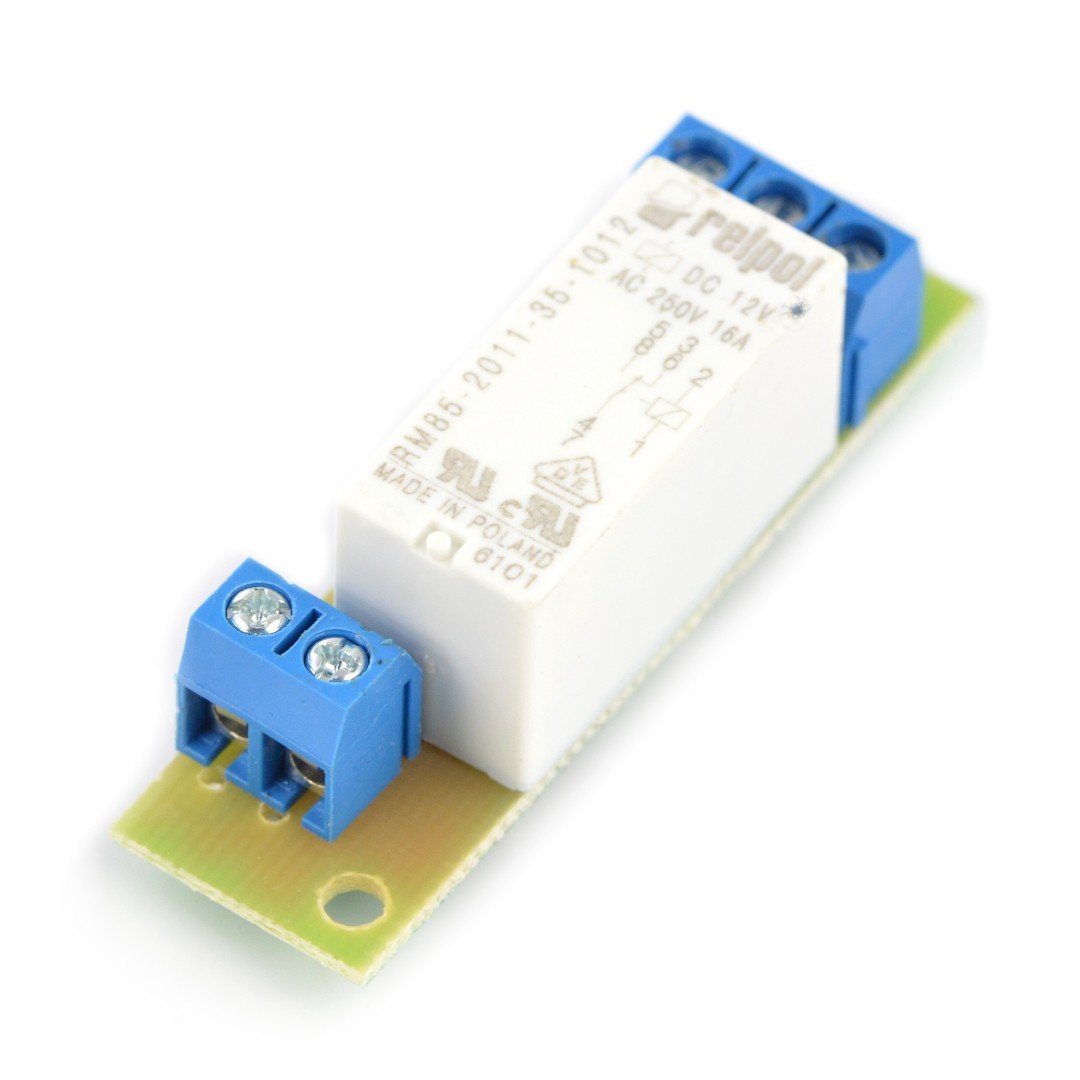

Etcher for circuit boards B327 - 100g

Printed circuit board etching agent. Dissolves very quickly and does not crystallise from the solution. It etch evenly, ensuring sharp contours and minimising irritation.Universal Developer for Photolakers and Positive Laminates - 22g

A product to develop photo-varnishes and positive plates. Provides good quality and sharpness of contours. It does not contain NaOH, which increases work safety.See also

Copper etchings. What is it?

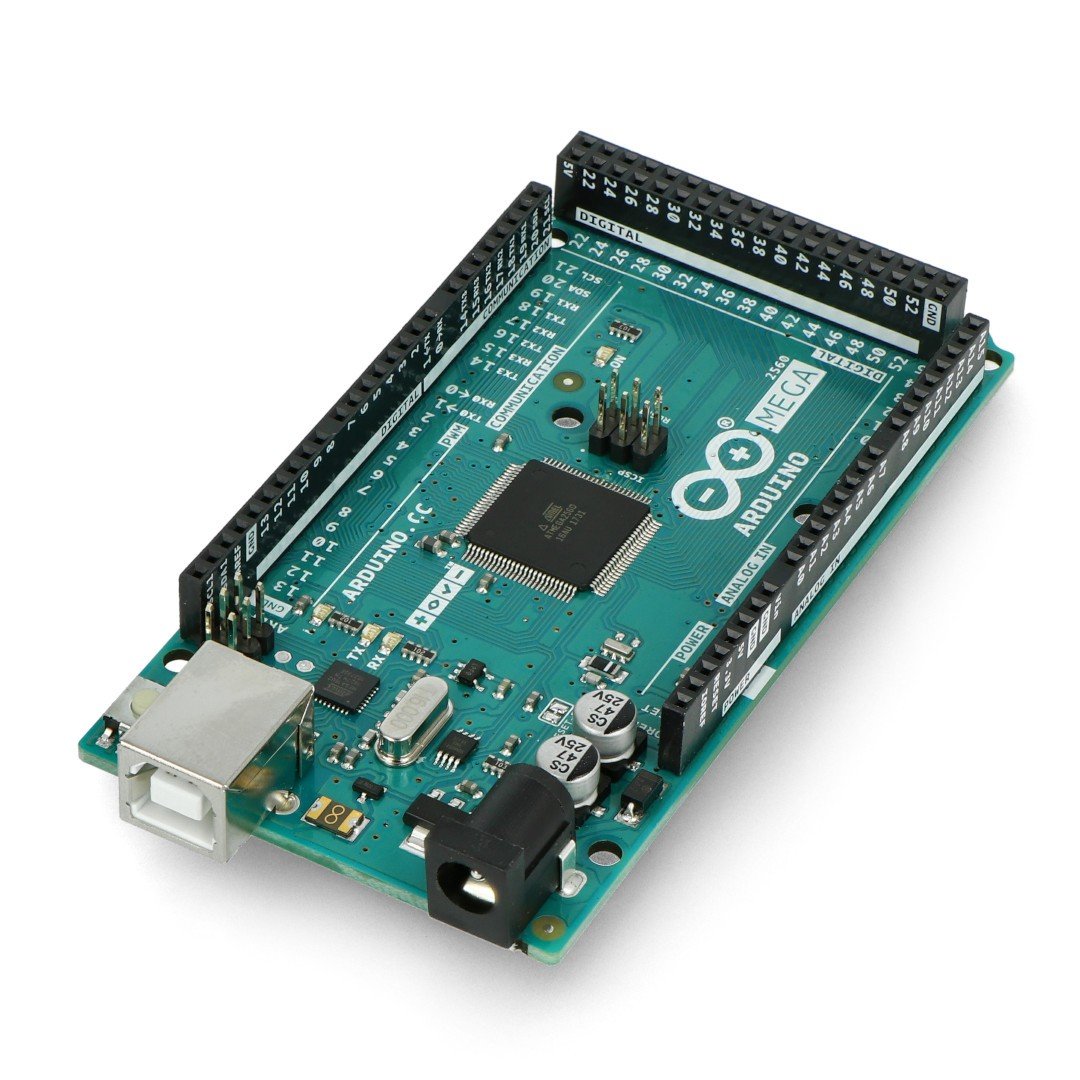

Printed circuit boards are the basis of virtually any electronic equipment. To produce them, you need a set of appropriate tools, knowledge and skills. One of the most important elements necessary for the manufacturing process is the etching machine offered in this category. It is a fine-crystalline, free-flowing sodium persulphate (B327), which when dissolved in water forms the target liquid. It is able to remove copper from the surface of the laminated plate. To protect the metal against etching, it is sufficient to cover it from above with a thin layer of suitable material. Until a dozen or so years ago, the process of manufacturing the plate was much more strenuous, time consuming and labour-intensive. It required manual application of the shape of the paths and then etching the uncovered copper parts. Today, photochemical technique is most often used for this purpose (for example, using a laminated plate with a photosensitive layer) or thermal transfer. In both cases, the process starts with a precise design of the paths on the board using dedicated electronics software (for example, the popular Eagle program). The project is printed on the appropriate material or technique and then transferred to the board. In the case of thermal transfer, using a strong heat source, the ink from the laser printer is transferred directly to the surface of the board (it is important to remember that the print is made in a mirror image of the actual project). If a technique using a plate with a photosensitive layer has been chosen, the path design is printed on a transparent foil in the negative (transparent fragments are places where the paths run). A suitable sized film is placed on a laminated plate and exposed to ultraviolet light. The transparent fragments let light through to the plate where the "protective coating" is cured. After the tile is placed in an etch solution - copper is removed wherever it is exposed to its direct action.

Copper etching machines - how to use?

It is very important to know the correct rules of handling the extruder before starting work - so as not to harm yourself, damage the equipment and perform the task properly. The basic issue is the right proportions of substances to mix: 100 g of etch should be mixed with about 20 ml of water, 250 g of etch should be mixed with half a litre of water and 500 g of etch should be dissolved in a litre of water. It is also very important to protect the surface of the skin from contact with the substance so as not to irritate it or transfer it to more sensitive areas (such as eyes or mucous membranes). For mixing the liquid and extracting the etched tile, you should prepare a suitable tool in advance - it can be made of wood or plastic, for example, but should not be metal. The container (bowl) in which the liquid will be contained should also not be made of metal. The temperature of the solution is also crucial - it should be about 40 or 50 degrees Celsius. During operation of the copper smelter it is worth to ensure constant movement of the liquid inside the container: it is best to simply gently move the previously prepared stirrer, taking care not to damage the plate (and protective layer of copper).

What exactly do we offer in this category?

In our offer you will find finely crystallised sodium persulphate (B327) in packages of different sizes. We have packages (foil) of 100 g, 250 g and a 500 g etch version. In our assortment there are also preparations designed for current-free copper tinning.