List of products by brand Cynel

Soft soldering is the most important technique for joining components in electronics. Even one incorrect, unstable connection can cause failure of the entire device. Not only the soldering technique itself but also the choice of proper solder should be taken into account. Its quality determines not only the quality of the assembly results and reliability of the connection, but even the ease of working on the assembly of components. The quality of solder is particularly important in the era of lead-free soldering, which is enforced by the EU RoHS directive. Recall that it introduced a ban on the use of certain substances, including lead, which translated into a real revolution in the production process of electronics. One of the most popular manufacturer of solder by electronic engineers is Cynel company.

- On sale!

- Promotion

Solder Cynel LC60 250g / 0,56mm

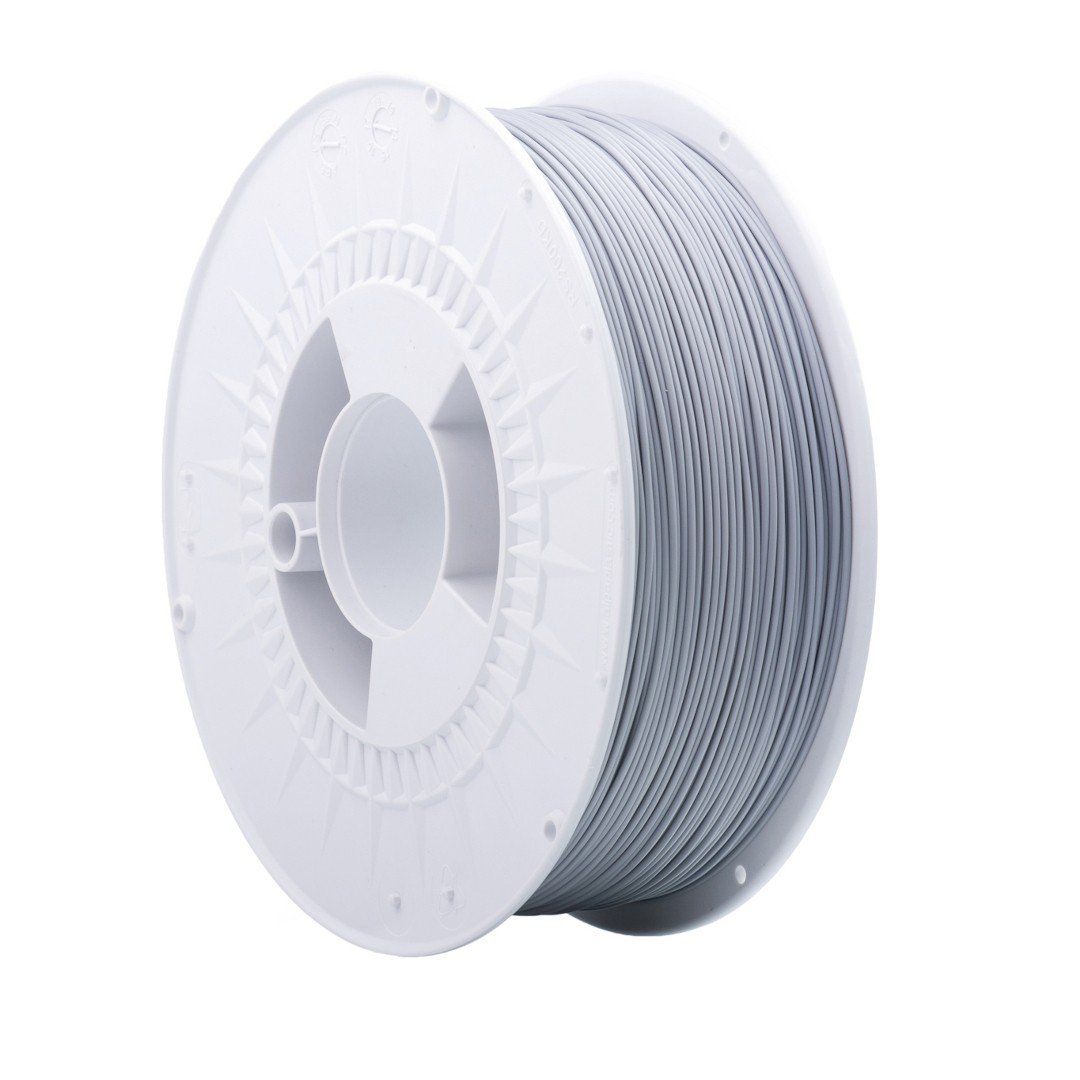

Soldering tin with flux of 0.56 mm diameter in a 250 g spool. Consists of Sn60Pb40. Wire diameter is 0.56 mm. Melts already at 190°C. Used in the electrical industry.Solder wire Cynel LC60 100g / 0.38mm

Soldering tin with flux, diameter 0.38 mm, in a 100 g spool.Soldering tin Cynel LC60 100g/1,00mm

Soldering tin with a diameter of 1.00 mm in a 100 g spool.Cynel LC60 - solder tin 100g / 0.7mm

Soldering tin with flux, diameter 0.70 mm, in a 100 g spool.Soldering tin in tube 16g / 1,00mm

Tin in a vial with a diameter of 1.00 mm and a mass of 16 g.- On sale!

- Promotion

Soldering tin in tube Cynel LC99,3 SW26 14g/1mm - lead-free

Lead-free solder placed in a plastic vial. The composition of the alloy is Sn99.3Cu0.7 . The vial contains 14 g of material with a diameter of 1 mm . Halide flux SW26...Solder Cynel LC99.3 100g/0,56mm - lead-free

Lead-free solder with flux 1.1.3 . The composition of the alloy is Sn99.3Cu0.7 . The weight of the material wound on a plastic spool is 100 g and its diameter is 0.56 mm...Solder Cynel LC99.3 100g/0,7mm - lead-free

Lead-free solder with flux 1.1.3 . The composition of the alloy is Sn99.3Cu0.7 . The plastic spool contains 100 g of material with a diameter of 0.7 mm . The melting...Solder Cynel LC99.3 100g/1mm - lead-free

Lead- free solder with flux 1.1.3 . The product is wound on a plastic spool. Its weight is 100 g and its diameter is 1 mm . The composition of the alloy is Sn99.3Cu0.7...Solder Cynel LC99,3 SW26 100g/0,6mm - lead-free

Solder tin without the addition of lead . SW26 halogen flux is designed for lead-free soldering. The product will be used in the electronics industry, both for professional...Solder Cynel LC99,3 SW26 100g/0,7mm - lead-free

Lead- free solder with SW26 flux. The composition of the alloy is Sn99.3Cu0.7 . The weight of the material wound on a plastic spool is 100 g and its diameter is 0.7 mm...Solder Cynel LC99,3 SW26 100g/1mm - lead-free

Lead -free solder with SW26 flux. The composition of the alloy is Sn99.3Cu0.7 . The weight of the material wound on a plastic spool is 100 g and its diameter is 1 mm ....Solder Cynel LC99 100g/0,56mm - lead-free

Lead- free solder with flux 1.1.3 . The composition of the alloy is Sn99Cu0.7Ag0.3 . The weight of the product wound on a plastic spool is 100 g and its diameter is...History of the brand

Cynel has been developing since 1984 and for years the brand name has been synonymous with high quality binder. The brand was based on the experience of experts from the Department of High Pressure Physics, Polish Academy of Sciences. They had powerful knowledge about forming plastic materials. Polish brand was a pioneer in the production of tin in the process of forming under high pressure, and its range included binders (then still tin-lead), available in many diameters and variants. Despite the passage of years, Cynel does not rest on its laurels, constantly expanding its offer (including soldering pastes and powders).

Wide selection of products

Today, the offer of Cynel Unipress (because this is its full name) includes a wide range of products for all varieties of electronics assembly process. For manual soldering there are solder wires with flux additive, produced in leaded version (primarily for the service of older equipment soldered in this technology) and lead-free (for new projects and service equipment manufactured in accordance with the RoHS Directive). Cynel 's product range could not miss classical colophony and high quality fluxes in the form of liquid. For reflow soldering, fluxes and special solder paste based on SAC305 alloy are dedicated, and for wave soldering (i.e. automatic soldering of boards in THT technology), flats and rods are dedicated, as well as special fluxes, including RMA type.

Cynel binders in Botland store

High quality Cynel solder wires based on tin-lead alloy LC60 (Sn60Pb40) have been introduced to Botland offer. They are available in many diameters, including: 0.38 mm, 0.7 mm, 1 mm, 1.2 mm, 1.5 mm, 2 mm, up to 3 mm. All binders are available in 100 g or 250 g net reel form. The alloy used for solder production comes from the first smelting of tin and lead. The melting point is between 183°C and 190°C and the working temperature is between 320°C and 420°C.