- New

- Page

- View all

- 3D print

- Minicomputers

- Electronics

- Sensors

- Robots & mechanics

- Tools & Power Supplies

- Education

- Smart Home

- Others

- 3D PRINTING

- View all

- 3D printers

- Filaments

- Filament dryers

- 3D scanners

- Creative kits for 3D projects

- Accessories for 3D printers

- Components for 3D printers construction

- 3D Pens

- CNC

- MINICOMPUTERS

- View all

- Raspberry Pi

- Arduino

- Nvidia

- Flipper Zero

- XIAO

- Odroid

- BBC micro:bit

- Other minicomputers

- PLC drivers

- M5Stack

- ESP32

- ELECTRONICS

- View all

- Computer accessories

- Automobile accessories

- Cooling

- Diodes

- Sound and acoustics

- Mounting components

- Passive elements

- Wearables (e-textiles, smart clothes)

- Cameras

- Consoles

- Memory cards & disks

- Communication

- Converters

- Electronics courses

- Microcontrollers

- Animal repellers

- LED lighting

- Programmers

- Relays

- Voltage regulators

- Artificial intelligence

- Motor drivers and servos

- Integrated circuits

- Displays and screens

- More...

- SENSORS

- View all

- Resistance sensors

- Inductive sensors

- Alarm sensors

- 9DoF IMU sensors

- Piezoelectric sensors

- Oxygen sensors

- Pressure sensors

- Twilight sensors

- Door sensors

- Hall effect sensors

- RPM sensors

- Gas sensors

- Optical sensors

- Tilt sensors

- Accelerometers

- Air quality sensors

- Sound sensors

- Gesture sensors

- Inductive contactless sensors

- Grove modules

- Gravity modules

- Limit switches

- Sensors of light and color

- Magnetic sensors

- Medical sensors

- Pressure sensors

- Sensors odbiciowe

- Distance sensors

- Weather sensors

- Liquid level sensors

- Current sensors

- Flow sensors

- Motion sensors

- Temperature sensors

- PT100 temperature probes

- Humidity sensors

- Fingerprint readers

- Encoders

- Photoresistors

- Phototransistors

- IR receivers

- Magnetometers

- Gyros

- Sensor sets

- More...

- TOOLS AND POWER SUPPLIES

- View all

- Tools

- Soldering

- Power supply

- Oscilloscopes

- Measuring instruments & devices

New products

Pakiet filamentów Refill Bambu Lab czarno-biały PLA - 5 szt.

- New

- Reduced price

- Pack

- Sale

- New

- Reduced price

- Pack

- Sale

Promotion products

- Sale

- Sale

Other tins

See also

Types and forms of soldering tin

Various forms of solder are available on the market, each suited to specific soldering techniques and tools. The most common is rosin-cored solder wire, which is suitable for hand soldering using an iron. More advanced processes utilize solder pastes, essential for surface mount technology (SMD), where application is automated using screen printing. The alloy composition is also an important criterion. These typically include lead-free solders compliant with the RoHS directive, used in modern electronics; lead-based solders, valued in repair shops for their ease of work and lower melting point; and special alloys with added silver or copper, which improve conductivity and mechanical strength. It is within the "other solders" group that you can find less standard products, rarely used, but crucial in specific applications.

Quality and safety standards

Modern electronics production requires rigorous standards, particularly regarding compliance with the RoHS directive, which limits the use of lead and other harmful substances. This is why repair shops often choose lead-free alloys, which, despite their slightly higher melting point, offer equally good mechanical and electrical properties. Tin purity is also important, as the absence of impurities helps prevent connection defects and conductivity issues. In practice, this translates into greater reliability and safety of finished devices.

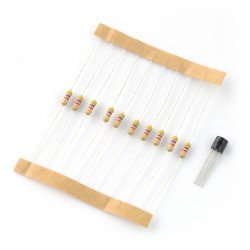

Why is it worth choosing less popular tins?

"Other" types of solder play a vital role wherever standard solders prove insufficient. Sometimes specific wire diameters are required, tailored to microscopic solder pads, while other times alloys resistant to high operating temperatures or high-humidity environments are required. This category offers solutions for advanced designers, professional repair shops, and enthusiasts seeking specific properties. These solutions enable the implementation of projects that defy standard applications while maintaining the highest quality and repeatability of connections.