BGA soldering stations

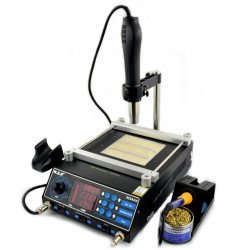

WEP 853AAA+ 3in1 soldering station - preheater + soldering tip + hotair with fan

Soldering station, which is a combination of hotair iron, tip-based soldering iron and heater. It has a total capacity of 1270 W. Equipped with a convenient temperature...Soldering station 3in1 Yihua 853AAA - preheater + + tip-based + hotair with fan

Soldering station, which is a combination of hotair iron, tip-based soldering iron and preheater. It has a total capacity of 1270 W. It is equipped, in particular, with a...WEP 853AAA 3in1 soldering station - preheater + soldering tip + hotair with fan in the flask

Soldering station which is a combination of hotair, soldering iron and heater. It has a total capacity of 1270 W. It is equipped in e.g. a convenient temperature regulation,...Yihua 853AA+ 3-in-1 BGA soldering station - preheater + grotto + hotair with fan in flask - 1270W

The Yihua 3-in-1 soldering station is an innovative combination of hotair , tip soldering iron and heater , with a total power of 1270 W. Perfect for precise work with...BGA soldering stations - application

The BGA soldering station is a tool intended for servicing BGA integrated circuits, which are a special case of surface-mounted elements (SMD). This type of assembly is used where it is necessary to replace damaged elements or reinstall them in order to correct assembly errors or eliminate defective soldering points where the tin could be chipped and contact lost (so-called cold solder joints). BGA elements are mounted on a special matrix composed of tin balls.

However, the use of BGA soldering stations is broader and may also include soldering other SMD integrated circuits, i.e. in QFN housings and other surface-mounted housings in which access to the soldering pads or their pin raster prevents or significantly impedes precise assembly using traditional soldering techniques. . The professional BGA station is perfect for all electronic services that specialize in, among others: in the repair of mobile phones, car controllers, computers and other similar devices.

BGA soldering stations - versatile, complete sets for professional service applications

The BGA soldering stations offered by our store, in addition to the heating plate, also have hot air blower modules and a tip soldering iron. Each module has independent temperature regulation. Thanks to this equipment, 3-in-1 BGA stations constitute a complete soldering set enabling most works related to servicing consumer and professional electronics devices and systems. Their operation is simple and intuitive. This section only offers devices for BGA soldering (assembly of BGA systems, including using lead technology) from renowned manufacturers. They have gained an established position on the soldering station market, among others: thanks to reliability and versatile use. In such devices, thanks to the microprocessor that is responsible for temperature regulation, the assembly and disassembly of BGA systems is efficient and trouble-free.

Infrared BGA soldering station in service practice - how to properly perform reballing?

Disassembly and assembly of BGA systems is a much more complex process compared to classic soldering with a tip soldering iron or hot air soldering iron. When repairing electronic devices based on BGA systems, it is necessary to have both the correct ability to operate the BGA station and the ability to assemble the BGA. After locating the damage, you should start desoldering the element that contains the cause of the failure (e.g. a processor in a BGA housing that has cold solder joints). First, we place the PCB (e.g. the motherboard of a PC or game console) on the heating plate (pre-heater) of the BGA soldering station. The upper surface of the housing of the integrated circuit to be reballed should be lubricated with a thick layer of gel flux (approx. 3 mm - 5 mm). Then, we turn on the heating plate and set its operating temperature to approx. 300°C and turn on hot air blowing from the top, setting its temperature to a higher one, i.e. approx. 310°C.

When we notice that the heated chip loses its grip on the PCB, we can turn off the BGA station and remove the desoldered chip using a suction cup. Now, using a soldering iron and a desoldering braid, clean the surface of the PCB and the underside of the integrated circuit from old tin balls. The next step is to clean both surfaces of flux residues with isopropanol. After evaporating the isopropanol, we apply a fresh layer of gel flux to the bottom surface of the BGA chip, followed by a stencil for applying the BGA tin balls. The application template must have exactly the same arrangement of holes and the distances between them as the solder pads on the surfaces of the integrated circuit and PCB. BGA balls should be placed so that they fill all the holes in the template. After removing the template, heat the underside of the IC with the BGA balls to solder them to the IC's solder points.

Now we lubricate the soldering pads on the PCB with fresh flux, position the integrated circuit on its surface and start soldering it. We place the PCB with the layout on the surface of the pre-heater heated to a temperature of approximately 300°C and a hot air blower to a temperature of 310°C. A properly soldered chip should not move laterally or longitudinally, but should adhere evenly to the PCB surface. After turning off the BGA station, just wash the flux with isopropanol and that's it!

BGA soldering stations - FAQ

For BGA soldering, the best solution is a heater soldering iron with precise temperature control, preferably a specialized BGA station. Remember to match the characteristics of the binder and flux as well as the soldering parameters to the properties of the soldered elements.