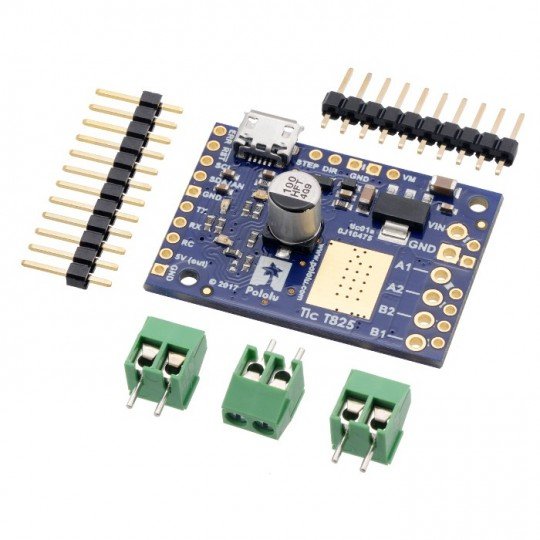

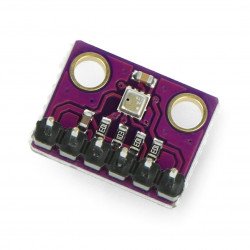

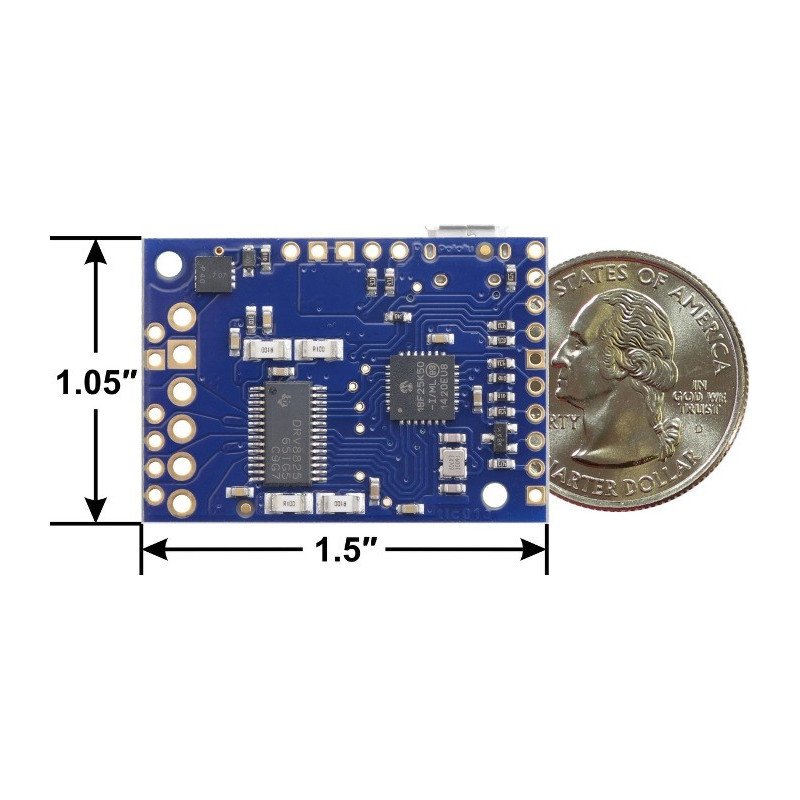

Product description: Tic T825 - USB 45 V / 2,5 A stepper motor driver - Pololu 3131

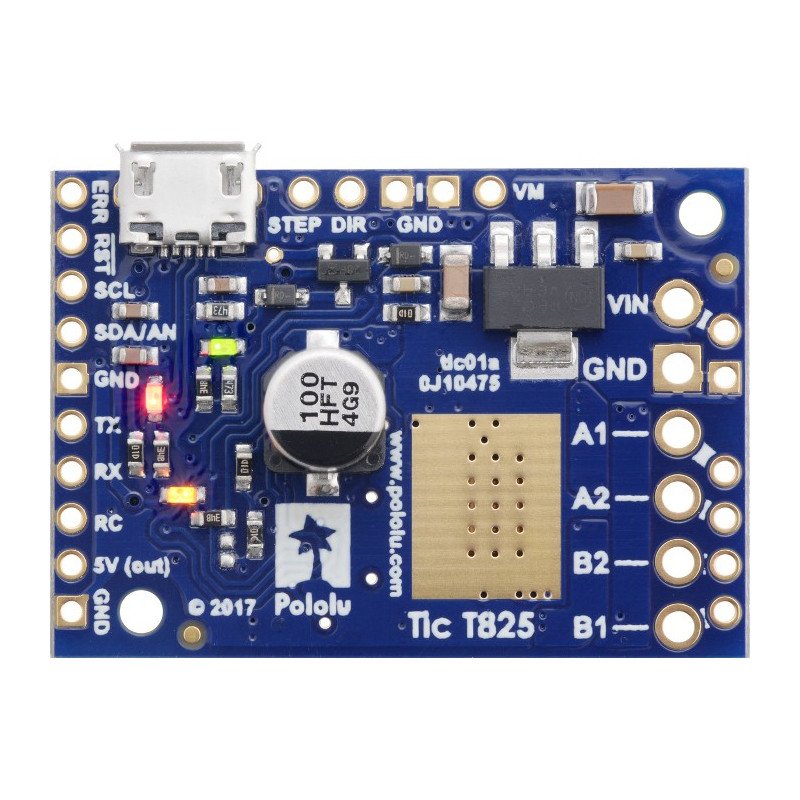

The chip allows you to control a step per motor with a device capable of generating logic states, such as Arduino, STM32Discovoery, Raspberry Pi or any microcontroller. The driver can be configured, tested, and monitored via USB, and runs on Windows, Linux, and macOS.

Features of the controller

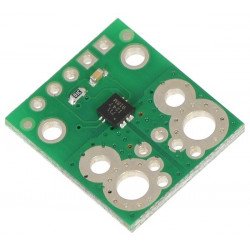

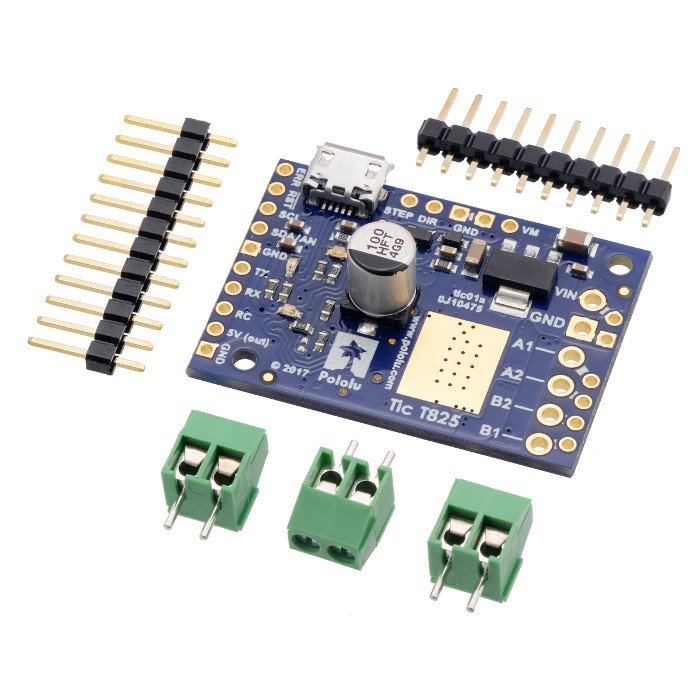

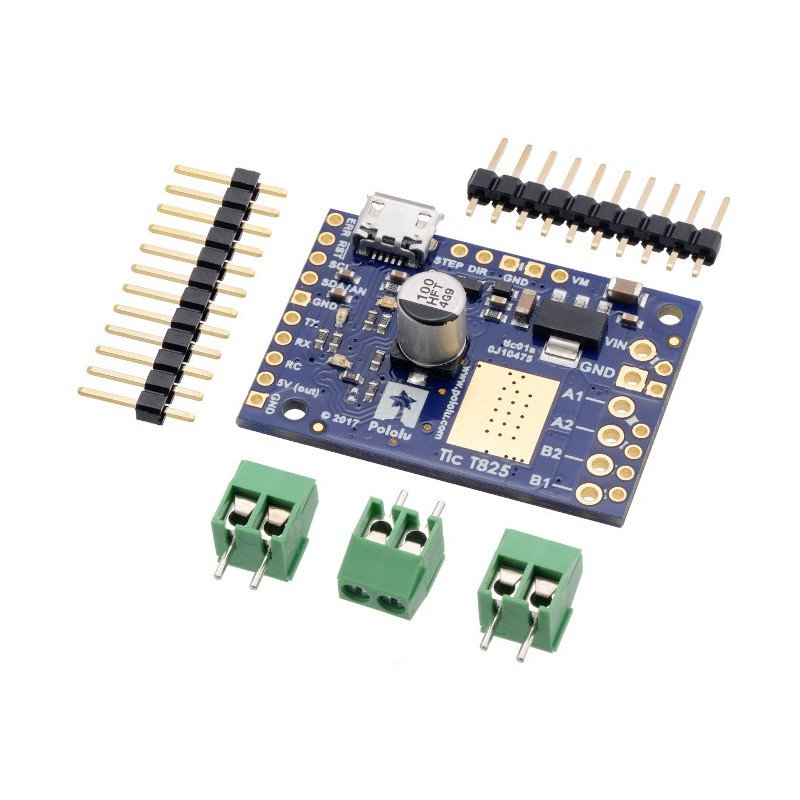

The Pololu module features very simple operation. In order to rotate the motor by one step it is enough to send a high state (logical one) to the STEP pin, the next sequence of zero and one will move the motor by the next step and so on. The selection of the direction is done by giving the appropriate state to the DIR pin (e.g. low state - clockwise rotation, high state - anticlockwise rotation). The driver can also select the resolution of motor operation. The module does not have soldered connectors, they are included for self-assembly.

We also offer a soldered module.

We also offer a soldered module.

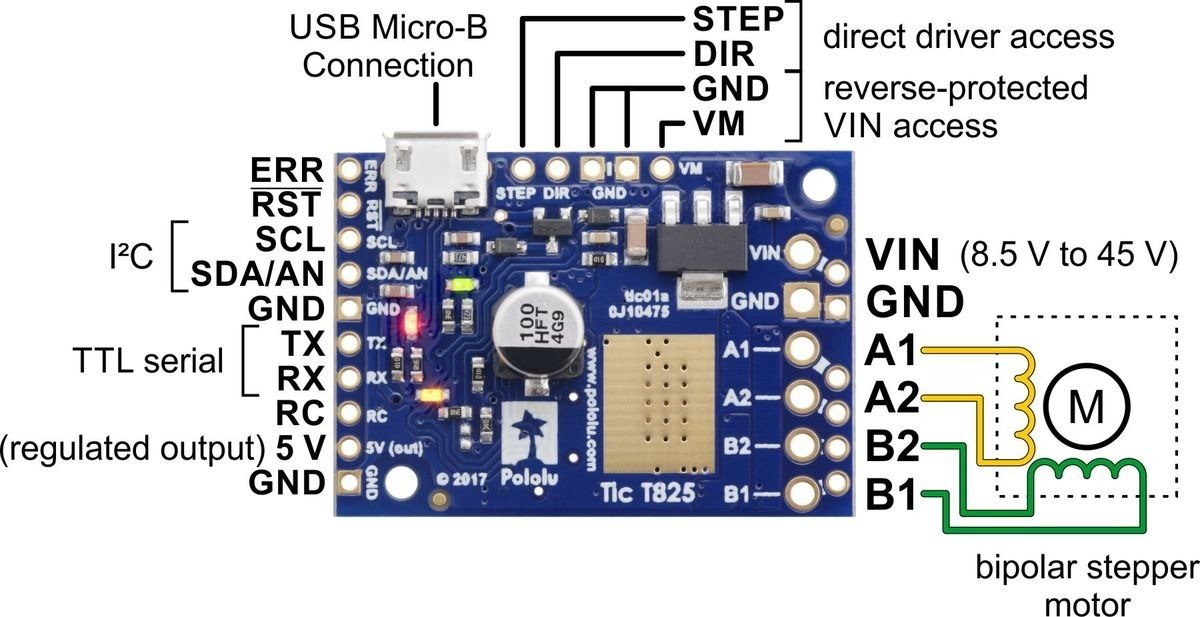

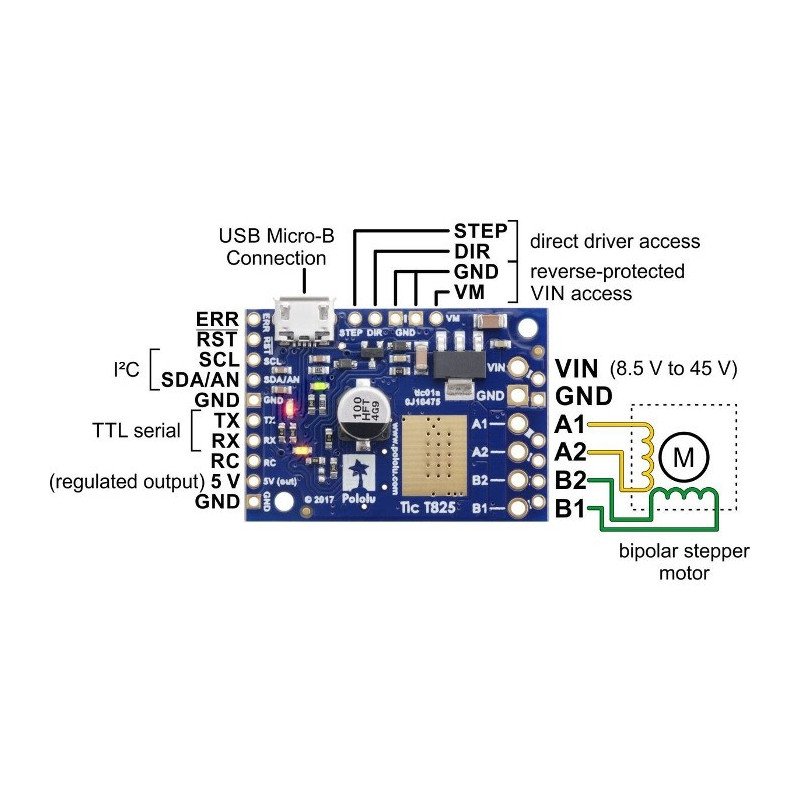

Controller connection and pinout description

To control a bipolar stepper motor you should connect the system according to the drawing below. If the nominal motor voltage is lower than the required driver supply (8.5V), set the current limit manually with a potentiometer.

The figure shows the minimum connection of the controller

|

The manufacturer provides a comprehensive user guide. |

Module power supply

A5V regulator is required to supply power (no external logic supply is required) tothe 5Vpin.The motor supply voltage from 8.5 V to 45 V is applied tothe VINpin. The circuit can be used to control motors with a nominal voltage lower than the required 8.5 V. To do this, limit the maximum current draw using a potentiometer, so as not to exceed the allowable motor current. For example, for a motor with a resistance of 5 Ω per coil and a current consumption of 1 A, the nominal supply voltage is 5 V. When supplied with 12 V, the current should be limited so that it does not exceed 1 A.

|

Caution! Connecting and disconnecting the motor while the controller is on can damage the system. |

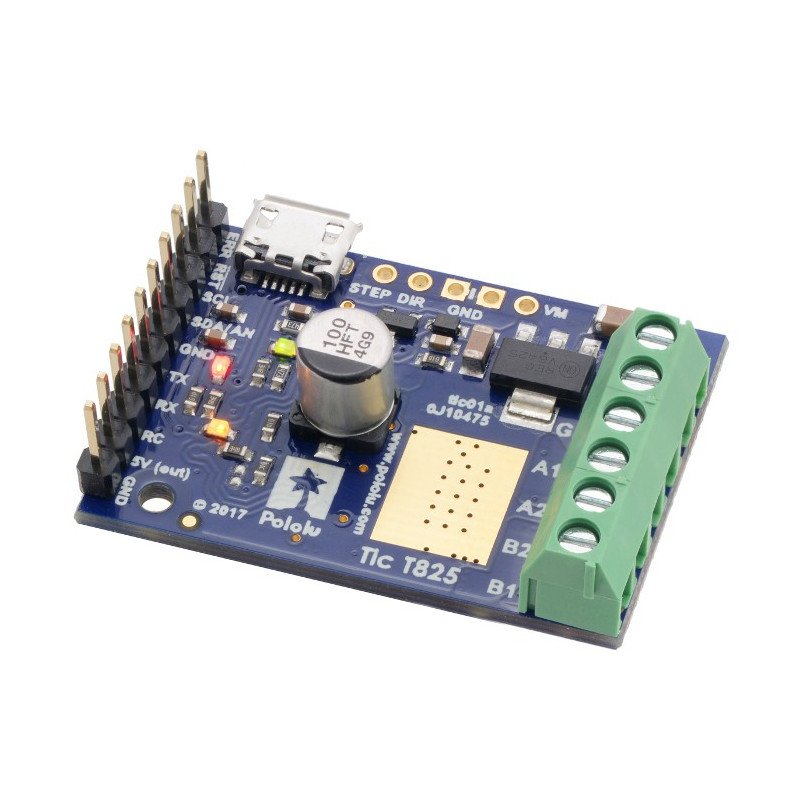

LEDs and heat dissipation

There are three LEDs on the board: green, red, yellow. Green indicates communication via USB. Red one is connected to the ERR pin, if it lights up, it means there is an error. Yellow indicates the stepper motor status and gives some information about errors, if any. Detailed description can be found in documentation on manufacturer website.

The board was designed to dissipate heat at a current consumption of approx. 1,5 A per coil. If the current will be much higher you should use external heat sink, for which you can use thermally conductive glue.

Technical specifications

- Motor supply voltage: 8.5 V - 45 V

- Current: max. 1.5 A per coil (with cooling up to 2.5 A)

- Supply voltage for logic part: 5 V regulator - no external power supply required

- Simple control interface

- Operation in 6 different modes: full step, 1/2, 1/4, 1/8, 1/16 and 1/32 step

- Adjustable current consumption by the motor using a potentiometer

- Protection against overheating of the system

- It has 6 control interfaces: USB, serial TTL, I2C, RC pulse servo, analog, square encoder

- Maximum step speed: 50000 steps per second

Kit includes:

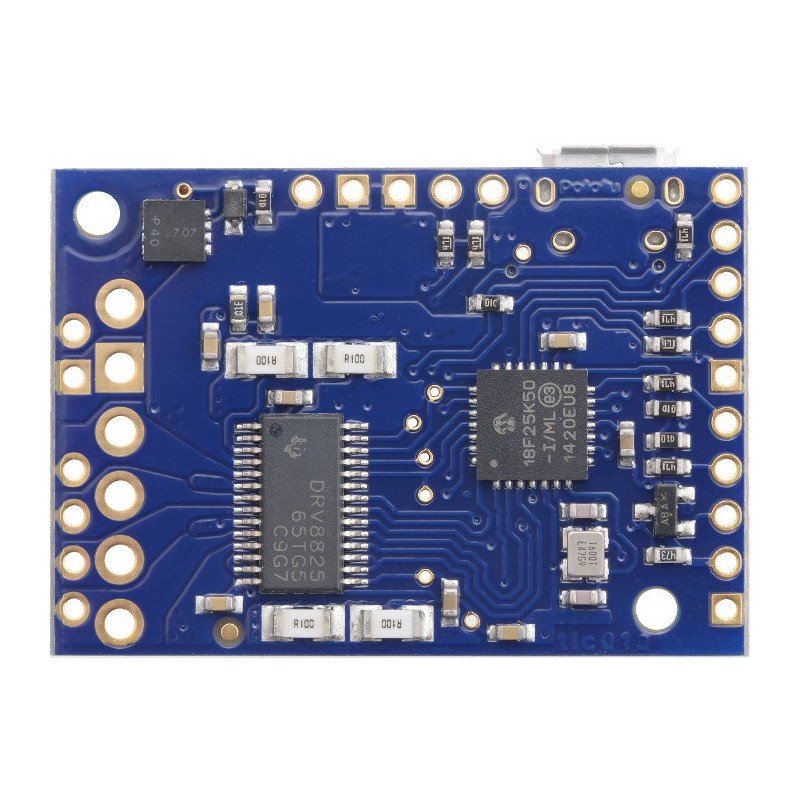

- DRV8825 stepper motor driver module

- Goldpin strips

- Screw connectors

Useful links |