In Botland you will find easy-to-use, stable and precise stepper motors drivers. These are intelligent and innovative PVC plates that enable the professional use of stepper motors in CNC devices (e.g. in 3D printers and plotters). Stepper motors are commonly used in such projects as automatic and robotic projects, manipulators, measuring devices, and scientific projects. Due to the fact that stepper motors are often placed in toys - interactive, walking and other - as well as related devices, the general use of stepper motor drivers is really very wide.

Stepper motor drivers

StepStick DRV8825 Stepper Motor Driver

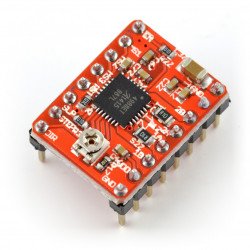

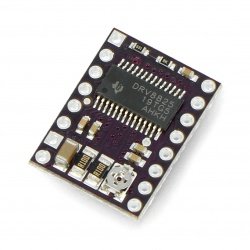

Stepper motor's driver based on the system DRV8825, allows you to control the motor with a current consumption of up to 1.5 A (with cooling of up to 2.2 A) per coil, at...Stepper motor driver A4988 RepRap - red

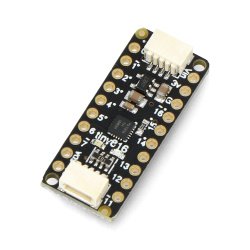

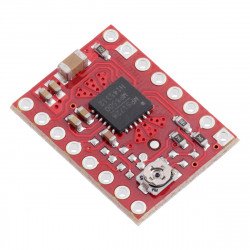

Stepper motor controller based on A4988. Powered from 8 - 35 V, with a maximum current consumption of 1 A per coil. Maximum resolution: 1/16 steps.MP6500 Stepper Motor Driver Carrier, Digital Current Control (Header Pins Soldered) - Pololu 2967

Stepper motor controller based on MP6500 system. Powered from 4.5 V to 35 V, with a maximum current consumption of 2.5 A per coil. Maximum resolution: 1/8th step. The module...A4988 - stepper motor driver RepRap 35V/2A - Pololu 1182

Stepper motor driver based on the A4988 system. Voltage supply in the range of 8 to 35 V with maximum current consumption of 2 A per coil. Maximum resolution: 1/16 of a step....DFRobot - motor driver 5,5V/1,5A for BBC micro:bit

An overlay for micro:bit to control four DC motors , two stepper motors and eight servos (5.5V/1.5A). Additionally the module has 9 I/O pins Micro:bit.Cytron Maker Drive MX1508 - two-channel motor controller 9.5V/1A

Simple to use, two-channel DC motor driver with H-bridge. 1 A continuous current per channel (1.5 A momentary). Power supply from 2.5 V to 9.5 V. Output current at 5 V is 0.2 A.DRV8834 stepper motor driver Low-Voltage 10,8V 2A - Pololu 2134

Stepper motor controller based on the DRV8834 system allows you to control a motor with a current consumption of up to 1.5 A (momentary up to 2 A) per coil, with voltage from...L298N - two-channel motor driver

Two-channel H-bridge. Supply voltage: max. 46 V. Max. instantaneous current 2 A. Housing: Multiwatt15 (THT).DRV8825 - stepper motor driver 45V / 2,2A - Pololu 2133

Stepper motor's driver based on the system DRV8825, allows you to control the motor with a current consumption of up to 1.5 A (with cooling up to 2.2 A) per coil, when...TB67S249FTG Stepper Motor Driver Carrier 47V/4,5A - Pololu 2973

Stepper motor driver based on TB67S249FTG chip. Powered by a voltage range of 10 - 47 V , with a maximum current consumption of 4.5 A per coil. Maximum resolution: 1 / 32...TB6612 - two-channel 13.5V / 1.2A motor driver with connectors - Adafruit 2448

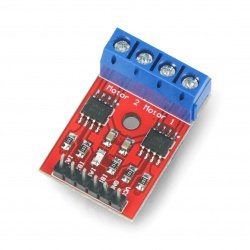

Dual-channel driver motors on the basis of the layout of the TB6612FNG . The voltage of the motors is d 4.5 V to 13.5 V and logic voltage ranges from 2.7 V to 5 V . The...MP6500 - stepper motor driver 35V / 2.5A - with analog current control - Pololu 2966

Stepper motor driver based on MP6500 chip . Powered by a voltage range of 4.5 - 35 V, with a maximum current consumption of 2.5 A per coil. Maximum resolution: 1/8 step. The...DRV8434S stepper motor driver 48V/2A SPI - Pololu 3768

Stepper motor driver module based on the DRV8434S chip from Texas Instruments. It is powered with the voltage in the range from 4.5 V to 48 V. It offers a wide range of step...Cytron Shield-MDD10 - two-channel DC motor driver - 7V-30V/10A - Shield for Arduino

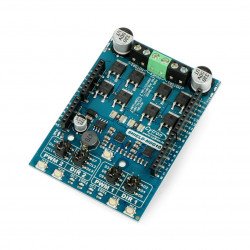

A module that allows you to control two DC motors or one stepper motor using Arduino. The overlay allows you to adjust the direction and speed of motors with current...DRV8434 stepper motor driver 48V/2A - with pin connectors - Pololu 3763

Stepper motor driver module with the DRV8434 chip from Texas Instruments, equipped with male pins for connection to a 16-pin socket or breadboard without the need for...Stepper motor driver L9110 12V/0,8A

The driver module uses L9110 chips to control one stepper motor or two DC motors. Supply voltage is from 3 V to 12 V. Continuous current up to 800 mA.TB6612 Motor Shield - 4x DC motor driver - 12V/1,2 A - Shield for Arduino

The module allows you to control four DC motors (DC), with two stepper motors or two servos using Arduino kits. The system allows you to adjust the direction and speed of...Grove - PCA9685 - 16-channel server driver, 12-bit PWM I2C

A 16-channel PWM generator useful when there is no microcontroller output. It allows, among others: controlling servomechanisms, adjusting motor speed or changing LED...Grove - L298N - two-channel motor controller 15V / 1A

Grove series module equipped with a two-channel H-bridge L298N , controlled by ATmege 8L. The circuit allows to regulate the direction of rotation of motors with maximum...Stepper Motor HAT - 2 channels - 28V/2,5A for Raspberry Pi - Waveshare 15669

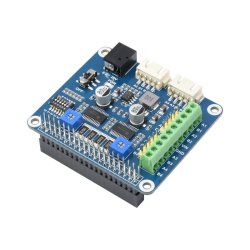

Shield for Rasberry Pi is equipped with a system DRV8825, it allows you to control two stepper motors with a resolution of steps of up to 1/32. It works with motors with a...Grove - L298P - two-channel motor driver 12V/2A - Seeedstudio 105020093

A module with an L298P motor controller that supports two DC motors or one stepper motor. The voltage supported by the controller is between 6 V and 12 V and the continuous...HRB8825 2-channel stepper motor driver 28V/2,5A - HAT For Raspberry Pi - Waveshare 22311

Two-channel stepper motor driver from Waveshare, in the form of a HAT shield for the Raspberry Pi. The controller is based on two HR8825 systems, it works with a voltage from...DRV8434 48V/2A stepper motor driver - Pololu 3762

Stepper motor driver module based on the DRV8434 chip from Texas Instruments. It offers a wide selection of step resolutions - from full step to 1/256 step and operates in...A4988 Black - stepper motor driver RepRap 35V/2A - Pololu 2128

Stepper motor driver based on the A4988 chip. Powered by a voltage range of 8 - 35 V, with a maximum current consumption of 2 A per coil. Maximum resolution: 1/16th of a step....How to choose a driver for a stepper motor

The stepper motor drivers selected by Botland store specialists allow you to precisely control the operation of one or several motors, bi- or unipolar, using signals from any system that generates logic states , such as: Arduino , Raspberry Pi , STM32Discovery, or microcontrollers. Thanks to them, the control of stepper motors is precise and intuitive. The stepper motor can be powered with voltage of different values, so before choosing a specific model, read its specifications.

Some models allow you to simultaneously connect DC motors, stepper motors and servomechanisms, as well as sensors, an LCD display, a memory card reader, or a Bluetooth module, which allows you to create more advanced projects. Others require the use of a heat sink to stabilize the temperature.

The standard system consists of a controller that takes pulse signals from the logic generating system and transforms them into a signal fed to the motor windings.

The stepper motor itself converts the impulse electrical signal from the controller into a sequence of movements. The direction of rotation is determined by the type of pulses supplied, the rotation speed depends on the pulse frequency, and the number of microsteps - on the number of pulses.

How to choose a stepper motor driver - current

The movement of the motor results from the interactions between the stator's permanent magnet and the variable magnetic field, which in turn is directly proportional to the current flowing in the windings. Therefore, when choosing a controller, you should first of all take into account the current consumed by the coils .

The controller should have a current capacity corresponding to the rated value of the motor. This value should not differ by more than ± 5% of the motor current.

In many controllers available in the Botland store, it is possible to limit the maximum current consumed by the stepper motor using a potentiometer located on the board.

It should also be remembered that stepper motors work all the time and consume the most current in the position-holding phase, which in turn causes the motor to heat up. Therefore, it may be necessary to use an appropriate heat sink to prevent damage to the controller and motor.

How to choose a stepper motor driver - voltage

When selecting a controller with a specific voltage range, one should mainly take into account the torque (power) of the motor, which depends directly on the speed of pulse rise (i.e. on the supply voltage) and the voltage resistance of the controller to the electromotive force generated by the motor.

The high supply voltage of the controller allows the current in the coils to increase quickly. Higher voltage means greater engine dynamics, and reducing the voltage causes deterioration of engine dynamics and speed.

In turn, the voltage resistance of the controller to the electromotive force (EMF) generated by the motor is crucial for failure-free operation of the system. Fortunately, motor manufacturers provide the EMF value in relation to the revolutions, which makes it very easy to select the appropriate controller. The position of the motor shaft also depends on the operation of the controller.

Additional information about stepper motors and drivers can be found in our guide Everything about stepper motors,

Stepper motor drivers - FAQ

When choosing a stepper motor controller, it is worth making sure that it is compatible with the device in terms of current and voltage. Some controllers allow you to connect more than one stepper motor, as well as DC motors , servomechanisms, sensors and other systems.

The stepper motor driver allows you to control the electrical signal (primarily voltage) supplied to the system. Based on the number and frequency of pulses sent to the engine, it is possible to control its operation.

After physically connecting the stepper motor to the controller, the parameters of the signal fed to the motor are set, which will determine the operation of the system. You can learn more from our article " Stepper motors - how does it work? ".

The division of steps depends on the motor control method. In full-step control, the smallest possible division is the rated division specified by the manufacturer. However, using half-step and micro-step control, it is possible to achieve virtually any division of steps.