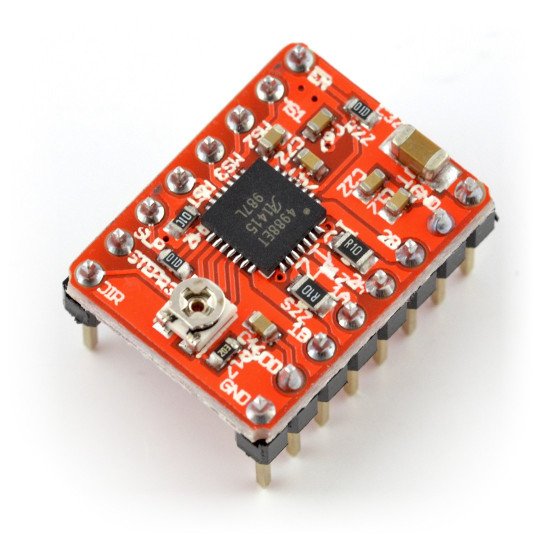

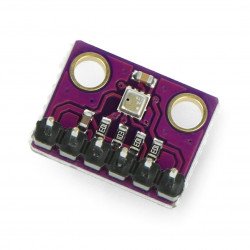

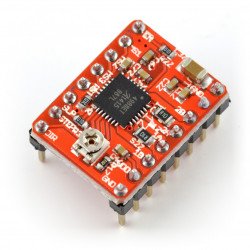

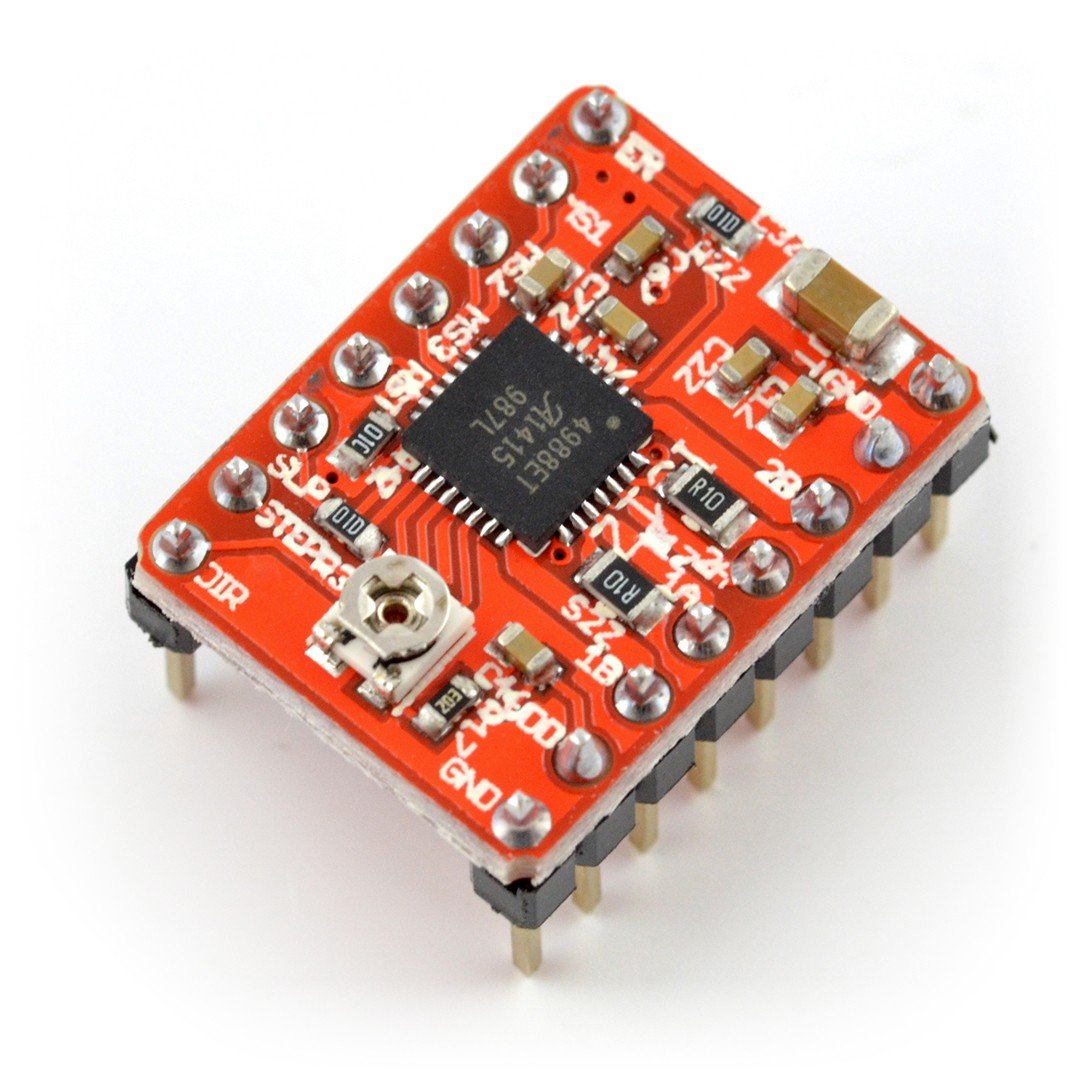

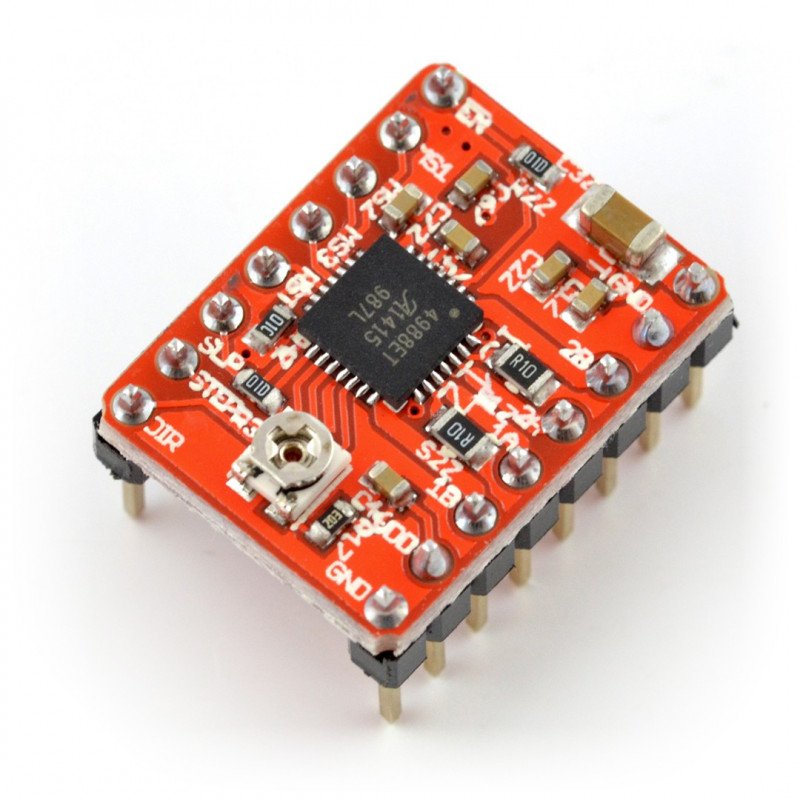

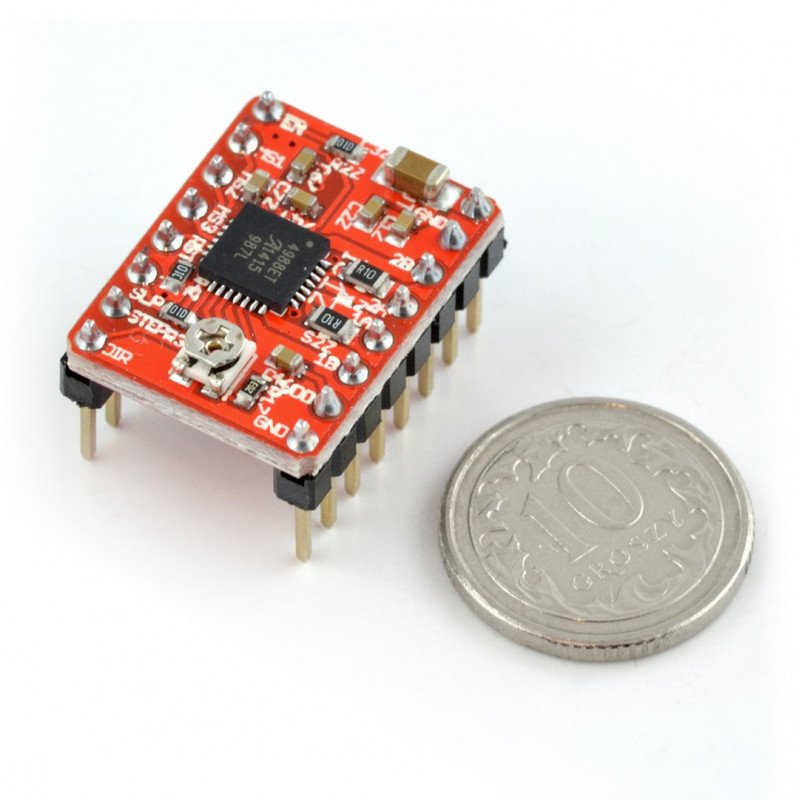

Product description:Stepper motorcontrollerA4988 RepRap - red

Dedicated to 3D printers, the A4988 driver allows you to control a stepper motor with active maximum current limitation.

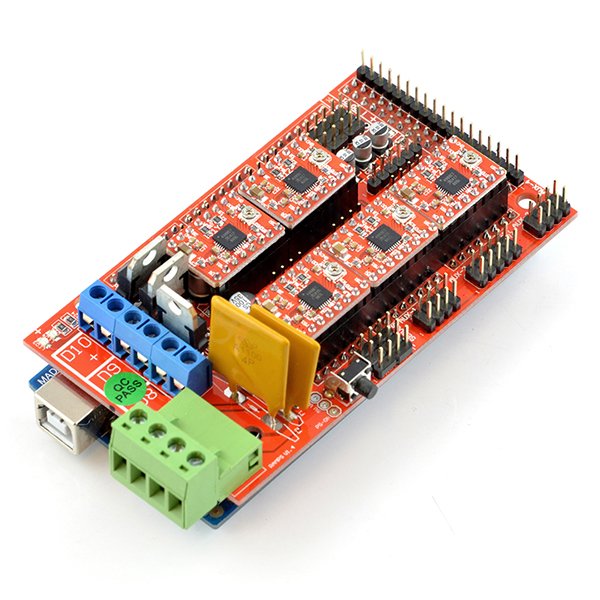

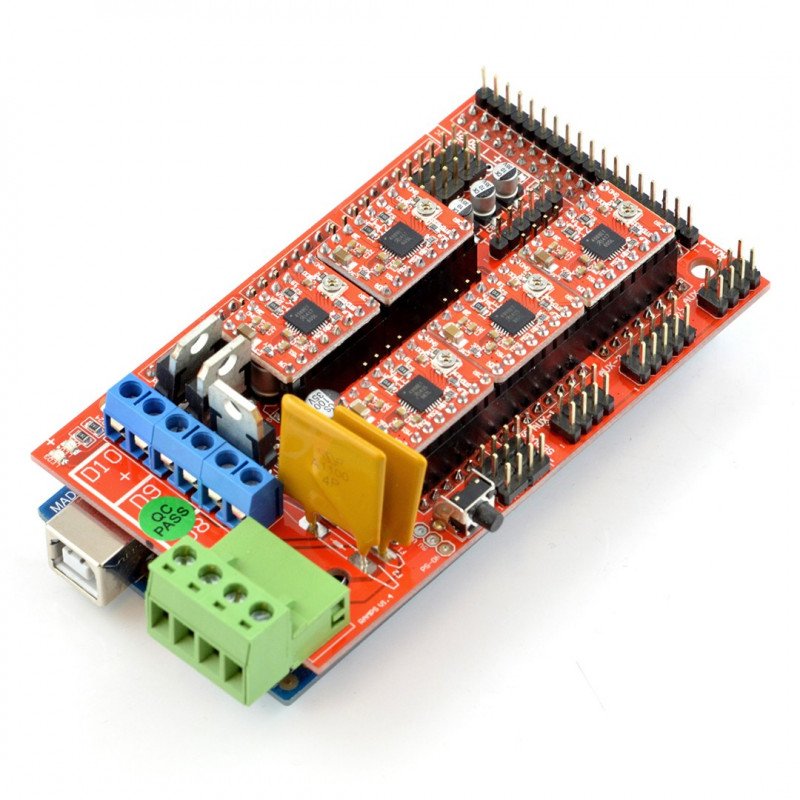

Ramps 1.4controller withArduino Mega 2560module and A4988 drivers connected.

|

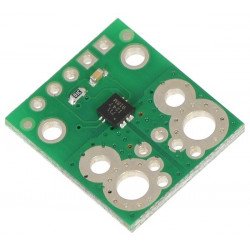

Although the quality of print and soldermask is not high, the controller retains its full utility values. In our offer you will also find high qualityA4988moduleby Pololu. |

Driver connection

To rotate the engine one step at a time, the STEP output must be set to high (logical one), the next sequence of zeroes and ones will move the engine one step at a time, and so on. The direction is selected by entering the appropriate state on the DIR output (e.g. low state - clockwise rotation, low state - opposite). The controller also has the possibility to select the resolution of the motor.

Power supply

To supply the logical part of the module, a voltage range from 3 V to 5.5 V is required, which must be applied to the pinVDD. The motor supply voltage from 8 V to 35 V is given per pinVMOT.

The system can be controlled by motors with a nominal voltage lower than the required 8 V. For this purpose, the maximum current consumption must be limited by means of a potentiometer so as not to exceed the permissible motor current. For example, for a motor with a resistance of 5 Ω per coil and a current consumption of 1 A, the nominal supply voltage is 5 V. When supplying 12 V, the current must be limited so that it does not exceed 1 A.

|

Attention! Connecting and disconnecting the motor while the controller is on can damage the system. |

Resolution

Step size is selected using MS1,MS2,MS3inputs. The possible settings are shown in the table below. Inputs MS1, MS2 and MS3 have an internal pull-down resistor (100 kΩ).

| MS1 | MS2 | MS3 | Resolution |

| low | low | low | Full step |

| high | low | low | 1/2 step |

| low | high | low | 1/4 step |

| high | high | low | 1/8th step |

| high | high | high | 1/16 step |

One pulse given on the STEP pin causes one motor step in the direction selected by giving the appropriate logical state on the DIR pin. The STEP and DIR outputs are not pulled up internally. If the motor is to turn in only one direction, the DIR pin can be permanently connected to VCC or GND.

The system has three more inputs to control power consumption: RESET SLP and EN are described inthe documentation. Please note that the RESET pin is not pulled up to anything. If it is not used, it can be connected to the adjacent SLEEP pin.

Current limitation of the controller

The system can be controlled by motors with a nominal voltage lower than the required 8 V. For this purpose, the maximum current consumption mustbe limitedby means of a potentiometer so as not to exceed the permissible motor current. For example, for a motor with a resistance of 5 Ω per coil and a current consumption of 1 A, the nominal supply voltage is 5 V. When supplying 12 V, the current must be limited so that it does not exceed 1 A.

Controller heat dissipation

The plate is designed to dissipate the heat at a current consumption of about 1A per coil. If the current is much higher, an externalheat sinkshould be used, which can be mounted withthermally conductiveadhesive.

Stepper motor driver specification

- Motor supply voltage: 8 V - 35 V

- Current: max. 1 A per coil

- The supply voltage of the logical part: 3 V - 5.5 V

- Simple control interface

- 5 different modes of operation: full step, 1/2, 1/4, 1/8 and 1/16 step

- Possibility to adjust the current drawn by the motor by means of a potentiometer

- Soldering goldpin connectors

Useful links |