Gears are elements that perform rotational motion that interact with each other through regularly spaced teeth, creating a gearbox for torque transmission. The use of gears allows you to change the speed of rotation of the object by a drive torqueand direction of rotation - the most popular example is the use of a rear transmission and in wheeled vehicles. The range gears, plastic plastic and aluminum variety, for the size and number of teeth, as well as sets, through the drive belts.

Gear wheels

Toothed belt 10x198mm + gear 12T - 8mm - 2 pieces

A set of belt and compatible gears . The circumference of the belt is approximately 198mm and the width is 10mm . The wheel has 12 teeth . The tooth surface width is...Pulley with Bearing - 18x8x3mm

Aluminum pulley with bearing. Diameter: 18 mm, height: 8 mm, hole diameter: 3 mm.- Reduced price

- SPECIAL OFFERS

Toothed Belt 10x198mm + Gear 12T - 5mm - 2pcs.

The kit of the belt and the compatible gears. The circuit of the belt is around 198 mm, and its width is 10 mm. The wheel has 12 teeth. The width of the tooth surface is 11.2...- Reduced price

- SPECIAL OFFERS

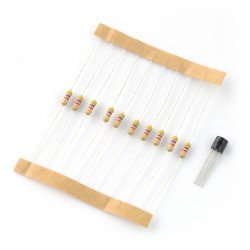

Worm gear, plastic, 6x10mm - white - 10pcs

A screw, i.e. a rotor for a worm gear, made of plastic. It has a cylindrical thread. The gear diameter is 6 mm and the overall length is 10 mm . It can be connected to two...Double Hanging Pulley - 9x19mm

Double, pendant, metal pulley with the width of 9 mm and a diameter of 19 mm. The wheel can rotate 360 °. The sizes of the whole is: 58 x 29 x 26 mm.- Sale

- SPECIAL OFFERS

- Reduced price

- SPECIAL OFFERS

- Reduced price

- SPECIAL OFFERS

Toothed belt 10x198mm + gear 12T - 6mm - 2 pieces

A set of belt and compatible gears . The circumference of the belt is approximately 198 mm and the width is 10mm . The wheel has 12 teeth. The tooth surface width is 11,2...Rubber V-belt - 2x90mm -10pcs.

Rubber belt used to transfer the drive e.g. from the motor shaft to another module, the thickness of the belt is 2 mm, the diameter is 90 mm. The set contains 10 pcs of belts.Toothed wheel 20T - 8mm - double

GT2 double gear wheel with 20 teeth. The width of a single wheel is 15 mm . The diameter of the holes is 2 mm.Set of Gears and Toothed Belts - 75pcs.

A set of gears, belts and pulleys in various sizes and shapes containing 75 pieces.Toothed wheel 16T - GT2 - 14x13x5mm

Aluminum gear wheel GT2 having 16 teeth . The product is a mounting element, which wheel diameter is 13 mm , height is equal to 14 mm and hole diameter is 5 mm .See also

Dimensional parameters of gears

The basic parameter of gears that you should pay attention to when selecting them for your project is the number of teeth arranged on the outer circumference of the wheel. The height of the tooth foot is also important. For gears with large teeth, it is easy to manually calculate their gear ratio due to the small number of teeth. However, in the case of a gear (enabling power transmission) with a large number of small teeth, selection for the project may prove problematic and it is best to rely on the documentation provided by the manufacturer. Each gear should be carefully described.

Gear parameters – continued

Another parameter determining the geometry of gears is their module , i.e. the size of a single tooth determined on the basis of the distance between the centers of identical tooth sides. The larger the module, the larger the teeth of the wheel. When selecting gears, their pitch diameter and outer diameter should also be taken into account.

The pitch diameter is determined by the straight line passing through the centers of the distance between the teeth on the circumference of the gear, and the outer diameter is determined by the straight line connecting the tips of the teeth placed opposite each other on the base circle of the gear.

The material should also be selected appropriately - we can choose between plastic and aluminum gears.

Operating parameters of gears

The performance of a gear transmission is determined by its operating parameters, i.e. torque, rotational speed and power. Torque represents the force applied to an arm of a specific length - for gears, torque depends on the diameter of the wheels between which it is transmitted. Additionally, we encourage you to check out the entire assortment of the assembly elements category, where you can find not only gears that mesh together, but also propellers , robot chassis , engine mounts , spacers , engine adapters and much more.

Gears – additional technical information

The rotational speed of the gear set determines the number of revolutions performed by the output wheel of the system in a specific time interval.

When a wheel with a larger diameter drives a wheel with a smaller diameter, then for one revolution of the larger wheel, the smaller wheel will make a greater number of revolutions in the same time interval - this solution is a gear that increases revolutions (higher wheel speed).

However, the smaller wheel driving the larger wheel is a system that allows the reduction of rotational speed. This solution is used when the design requires a lower speed on the gears.

Gear wheel – what else is worth knowing about it?

The size ratio of two mating wheels is linearly proportional to the changes in speed and torque between them. In turn, the power of the gear system determines the maximum amount of energy that the system can provide for a unit time (during the rotation of the wheels).

The power value of the gear is also significantly influenced by the power at the output of the gear driving system, e.g. on the engine shaft, while the power at the gear output remains constant, regardless of the dimensions of the gears constituting the gear.

Gears can be part of a gear ring, which has a higher load capacity compared to standard gears. The gear ring is usually composed of identical elements.

Gears - FAQ

Gears are the basic elements of power transmission in precision mechanisms, vehicles and many other areas of technology. They allow you to reduce speed and increase torque (or, on the contrary, increase rotational speed while reducing torque), as well as reverse the direction of rotation, e.g. given by an electric motor .

The invention of wheels and gears is attributed to the ancient Greeks of Alexandria, who worked on simple mechanisms in the third century BC. It is worth adding, however, that some historians trace the existence of gear wheels in Chinese chariots from the 27th century BC.