Chemistry and electronics are two areas that have much in common. Various types of chemical reagents are used in the development of electronic circuits and robotics projects. Specialist preparations are needed at practically every stage of the project, both in production, as well as in protection and assembly. Let's not forget about maintenance and necessary overhauls and, if necessary, repairs, where chemicals help to effectively restore the correct operation of robots and equipment. In Botland's offer there are preparations adapted to electronics and mechanics. They will work well in a domestic workshop, as well as in a professional studio. They are designed for maintenance, repair, protection and assembly. We recommend, among others, compressed air, conductive paints, lubricants and cleaners, thermally conductive tapes, protective varnishes and etchings. Check our offer and complete your equipment with chemicals dedicated for DIY enthusiasts, robots and electronics.

Chemia, preparaty do elektroniki

Etcher for circuit boards B327 - 100g

Printed circuit board etching agent. Dissolves very quickly and does not crystallise from the solution. It etch evenly, ensuring sharp contours and minimising irritation.Kontakt IPA Plus - isopropyl alcohol - 1000ml

A preparation designed to remove dirt from optical elements. Contains isopropyl alcohol. Evaporates quickly and leaves no traces. Capacity: 1000 ml.Soldering paste Easy Print Sn62 Pb36 Ag2 - 6g syringe

Paste type No Clean for soldering SMD components. Consists of metal powders, solvent-based flux and resin and activators removing oxide and thixotropic additives.- Reduced price

- Promotion

Royal Resin Crystal epoxy resin 1kg - casting - colorless

Royal Resin's colourless epoxy resin . It consists of two components: resin and hardener, which should be mixed in the ratio 1:0,27 . Crystal clear and colourless with high...Kontakt IPA Plus - isopropyl alcohol - spray with brush 400ml

A preparation designed to remove impurities from optical elements. Contains isopropyl alcohol. It evaporates quickly and leaves no traces. Capacity: 400 ml.Soldering paste Easy Print Sn96.5 Ag3 Cu0.5 - syringe 1.4ml

Paste type No Clean for soldering SMD components. Based on a welding flux No Clean. It is characterized by good adhesion and dampness of the soldered surface. Works with...Kontakt IPA - isopropyl alcohol - Spray 300ml

A preparation designed to remove impurities from optical elements. Contains isopropyl alcohol. It evaporates quickly and leaves no traces. Capacity: 300 ml.Kontakt IPA plus - isopropyl alcohol - with a sprayer - 250ml

High purity isopropyl alcohol "IPA" designed to remove oils and greases , and to care for and clean all kinds of readers. The product evaporates quickly and completely...Thermal conductive tape AG Thermopad 20x130x2mm - 6W / mK

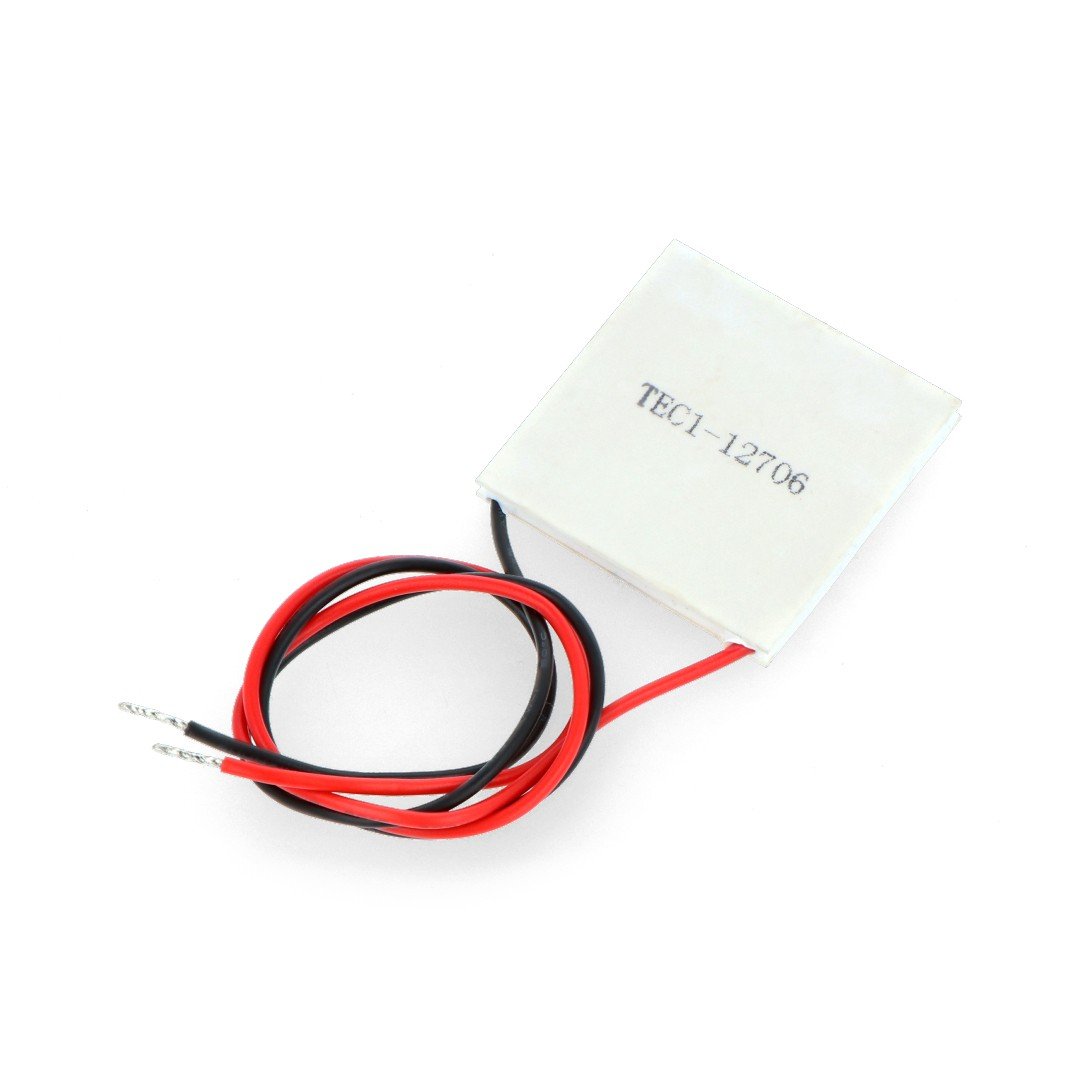

The tape improves heat transfer between electronic components. Used in places where the use of thermal conductive paste is not possible. The tape is double sided adhesive....Thermal conductive tape Thermopad 20x130x2mm - 2.4W / mK

The tape improves heat transfer between electronic components. Used in places where the use of thermal conductive paste is not possible. The tape is double sided adhesive....Thermal conductive tape thermopad 30x30x2mm - 2.4W / mK

The tape improves heat transfer between electronic components. Used in places where the use of thermal conductive paste is not possible. The tape is double sided adhesive....Thermal silicone paste - 25g syringe

The paste improves the heat transfer between the heat sink and the electronic element. It protects the system against atmospheric factors and is resistant to: oxidation, action...Thermally Conductive Adhesive transfer tape - 25x25x0.25mm - 0.6 W/mk

The tape improves heat transfer between electronic components. Used in places where the use of thermal conductive paste is not possible. The tape is double sided adhesive. The...Royal Resin Crystal epoxy resin 0,5kg - casting - colorless

Two component epoxy resin from Royal Resin. Crystal clear and colourless with a high gloss finish. It is UV resistant as well as waterproof, so it can be used wherever...AG Extreme thermal paste - 3g syringe

The paste improves heat transfer between the heatsink and electronic components. It protects the system against weather conditions. The substance is dielectric.AG Silver thermal paste - 3g syringe

The paste improves the heat transfer between the radiator and the electronic element. It protects the system from the external conditions. The substance contains silver...Thermal conductive tape AG Thermopad 30x30x2mm - 6W / mK

The tape improves the flow of the heat between electronic elements. It is used in places where it is not possible to use thermal-conductive paste. Tape is double-sided...Electronics chemistry - both basic and advanced

The electronic circuit will only work well and for a long time if it is properly secured. This includes soldered and printed circuits. Special attention should be paid to difficult environmental conditions, in which increased protection is required. For this purpose, protective varnishes and epoxy resins are used. They are characterized by properties allowing for effective protection against dust and moisture as well as short circuits and increased leakage currents. Protective varnishes are available in various variants. The choice should depend on the place of application. In spray form, they are ideal for evenly covering larger surfaces. If we protect small elements, additionally located in more difficult to reach places, a good choice will be liquid paint, which we apply with a brush. We also recommend conductive varnishes. Their task is to repair damage to, among others, membrane keypad contact fields.

In the case of SoC processors and integrated motor controllers thermally conductive pastes are used, which are responsible for receiving heat from high power elements. Compressed air is used to clean the corners of the components, which should be included in the equipment of every electronics. They also use various types of lubricants with lubricating and reducing friction between two moving elements. If you're into simple circuit boards, check out the BareConductive range of conductive inks.

Printed circuit board production. What kind of chemistry do you need?

Printed circuit boards are produced by both amateurs and professionals. Chemicals will prove their worth in any of these cases, both in simple, hobby projects and professional prototyping. It is then obligatory to supply an etch (sodium sulfate). It is designed for the etching of high-quality printed circuits. It also minimizes the risk of harmful etching and copper damage. With the etch press, the etching process is faster. However, it is also worth taking care of the right conditions, i.e. maintaining the correct temperature and movement of the liquid.

In the production of printed circuit boards, a reagent and a developer for photolacquers will also be useful. During soldering, you should use preparations for the current-free tinning of copper, which greatly facilitates and accelerates this process. It effectively protects the paths against dangerous oxidation.

The range of chemistry in Botland is very diverse. We have prepared for amateurs and experienced robots and electronics technicians basic maintenance measures, as well as preparations that definitely facilitate work at individual stages of projects. In addition, they show the ability to improve the performance of systems, robots and machines, protect against external factors and possible damage. Check what we can offer you! Choose the chemical agents best suited to your standards and work specifications.