- Sale

Delivery on a pallet

Due to the size of the product, your order will be shipped on a pallet. Delivery does not include lifting, meaning the courier is not obligated to lift the pallet to the height specified by the customer. Delivery time is 2-4 business days.

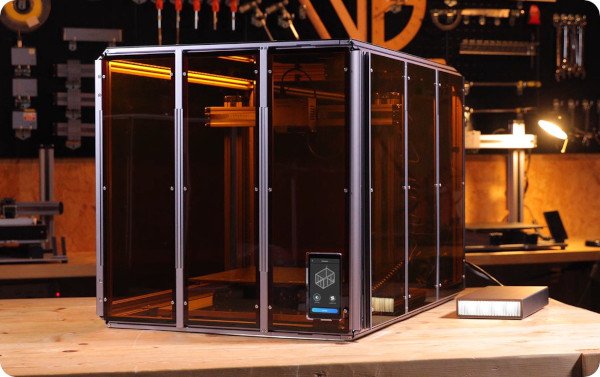

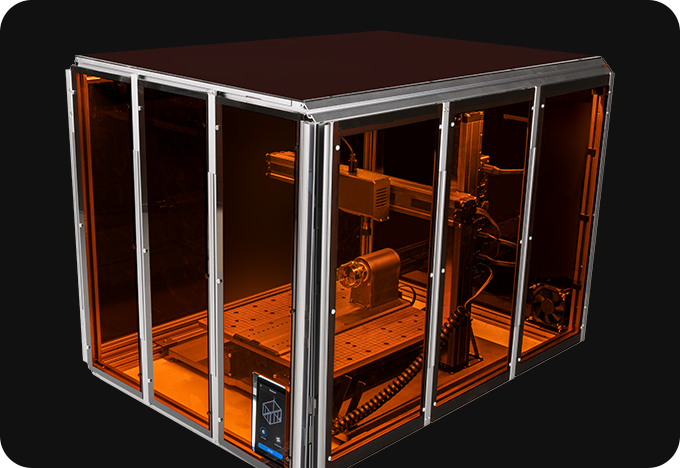

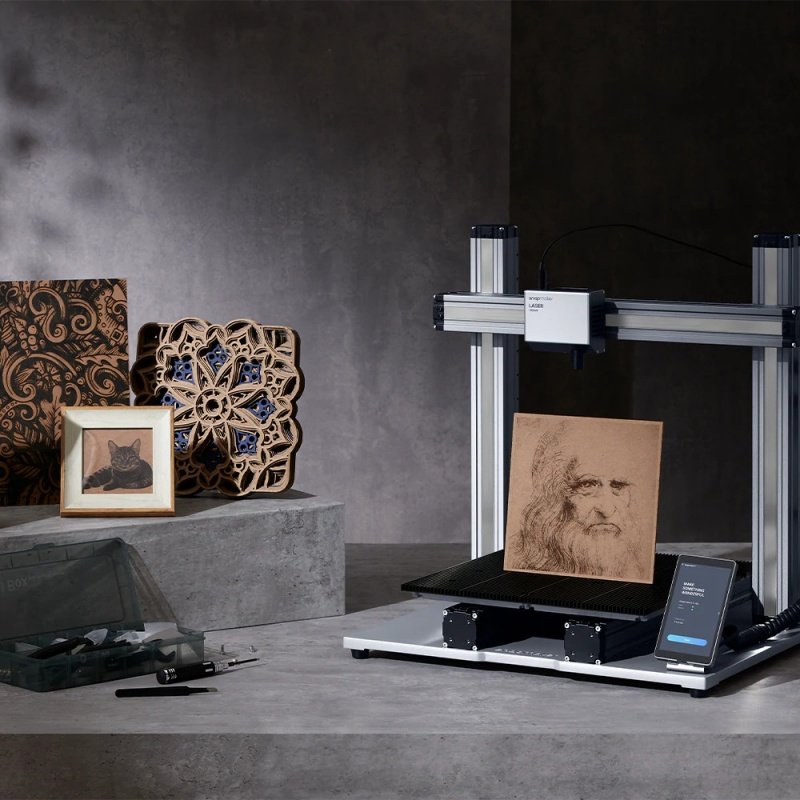

Product description: 3D Printer Snapmaker v2.0 3 in 1 model A350T - laser module, CNC, 3D printing in enclosure

Set that includes Snapmaker A350T version 2.0 multifunction device and a chamber designed to increase safety while working with Snapmaker. The device is made entirely of metal, assembly is quick and easy and the whole structure is very stable. The working area of Snapmaker A350T is 320 x 330 x 350 mm. It comes with modules for printing with 1.75mm diameter filament, laser engraving and CNC sculpting.

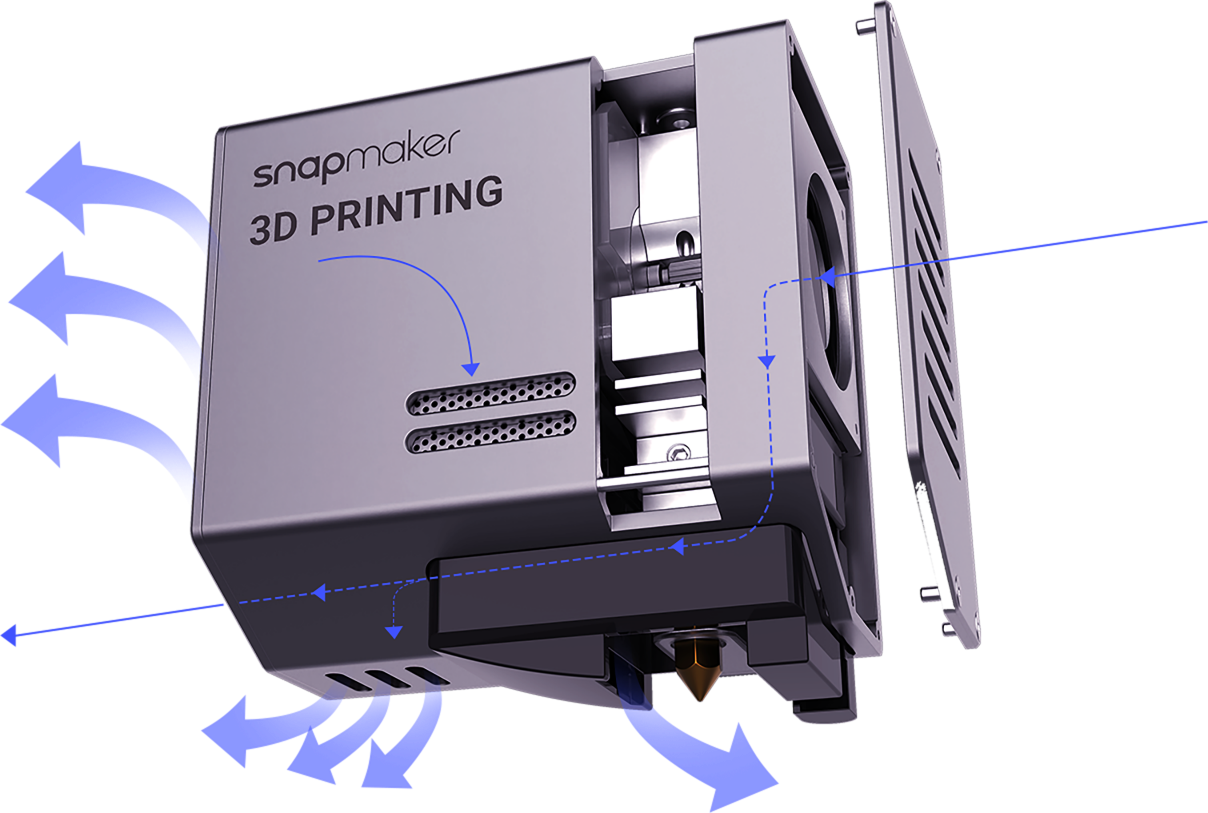

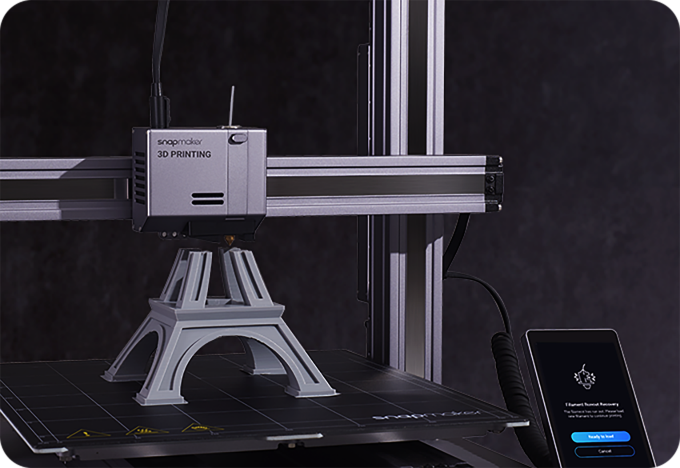

Snapmaker 2.0 3D printing module.

3D printing, the flagship feature of Snapmaker 2.0

Thanks to the stable design of the device and the technologies used, Snapmaker 2.0 allows for fast and precise printing. The device is ideal for beginners, if only because it has very intuitive software to operate the device in printer mode. Those who are more advanced will also find something for themselves here, as they will be able to personalize the printing options. Thanks to the heated work platform and the direct type extruder we can use many printing materials. Finally, the problems with flexible filaments are over!

Improved version of Snapmaker 2.0 A350T

Snapmaker 2.0 A350T version introduces several improvements over the original model. These allow for faster and quieter printing. The changes primarily include newly designed linear modules and improvements to the 3D printing features. Modifications also included a power module with intelligent fan speed control.

New stepper motor drivers and line module improvements

The Snapmaker 2.0 A350T 3D printer features the TMC2209 silent stepper motor drivers. They effectively reduce the noise generated during the operation of the device. In the linear modules, the manufacturer modified the screw rods of the X and Y axes, increasing their stroke from 8 mm to 20 mm. This procedure allowed to increase the speed and stability of A350T operation.

Improved power module

The new A350T power module uses a much quieter fan whose speed can be automatically adjusted according to real-time temperature. This reduces the noise level by about 16 dBA, making it even more comfortable to use.

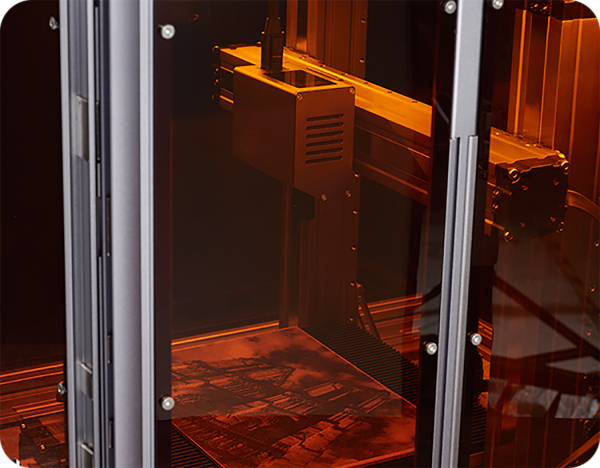

Enclosure included

Snapmaker 2.0 A350T is sold with a dedicated case. It has the following performance features:

- Convenient to use folding acrylic door

- Enclosed with acrylic panels to protect the user while using the laser module

- Equipped with a door opening sensor

- Exhaust fan

- LED lighting

Improved printhead

The printhead has been redesigned with an improved cooling system, quick hot-swap hot-end system and improved quality of the extruder parts which significantly improves the quality and consistency of the print.

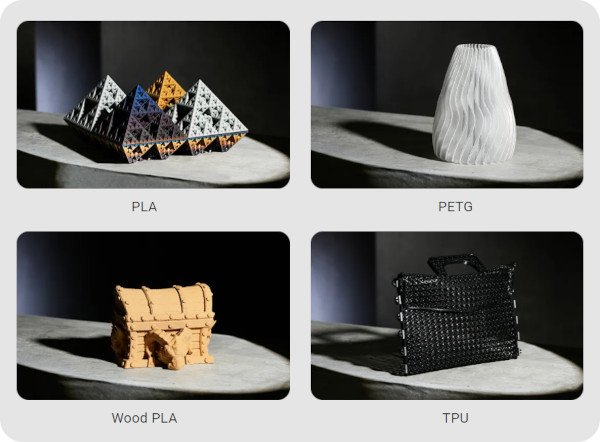

Variety of supported materials

The printer supports various types of materials such as PLA, ABS, PETG, TPU, PP, WoodFill and LayBrick. You can choose layer thicknesses from 0.05 to 0.3 mm.

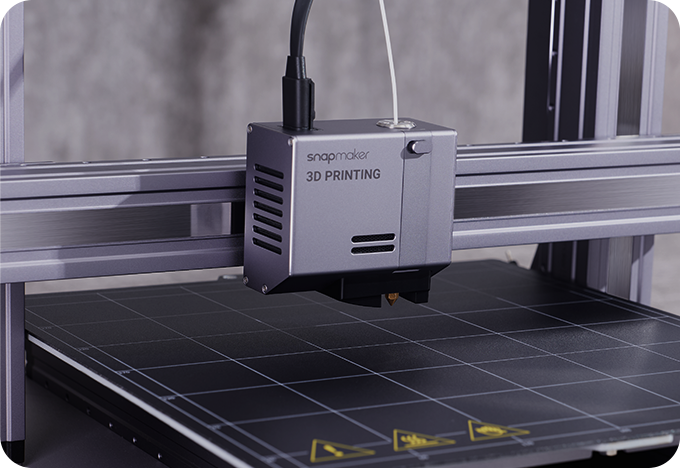

Automatic levelling

The printer is equipped with a proximity sensor, so the table calibration is done automatically. You can switch to manual mode and calibrate the table yourself.

Felt sensor

Precise sensor constantly monitors the state of the filament and in case of its lack stops the printing without damaging the printout. After refilling the material it is possible to resume printing.

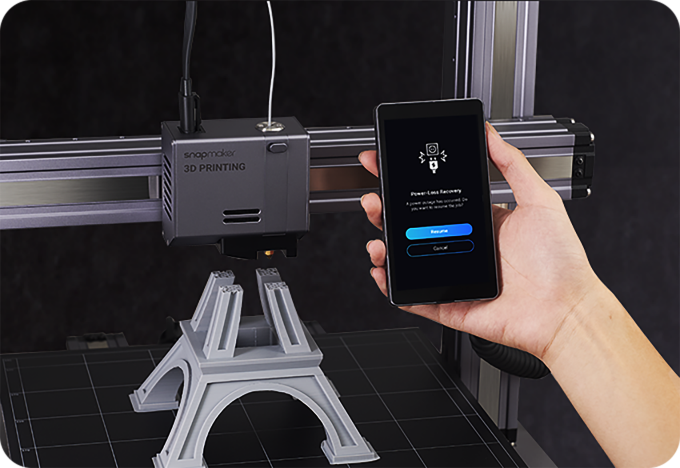

Resume operation after power failure

SnapMaker 2.0 allows you to quickly resume printing after a power loss. To do this, simply press the "resume" button on the touch screen.

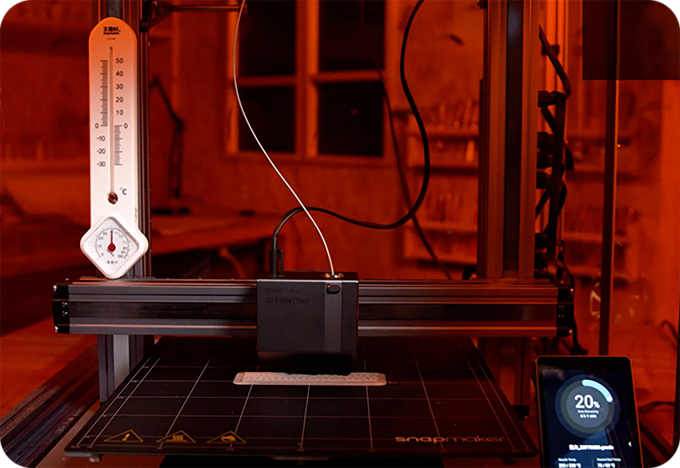

Enclosure included

The use of housing allows you to maintain a constant temperature during printing, which greatly facilitates the work with filaments such as ABS without the risk of deformation of the print.

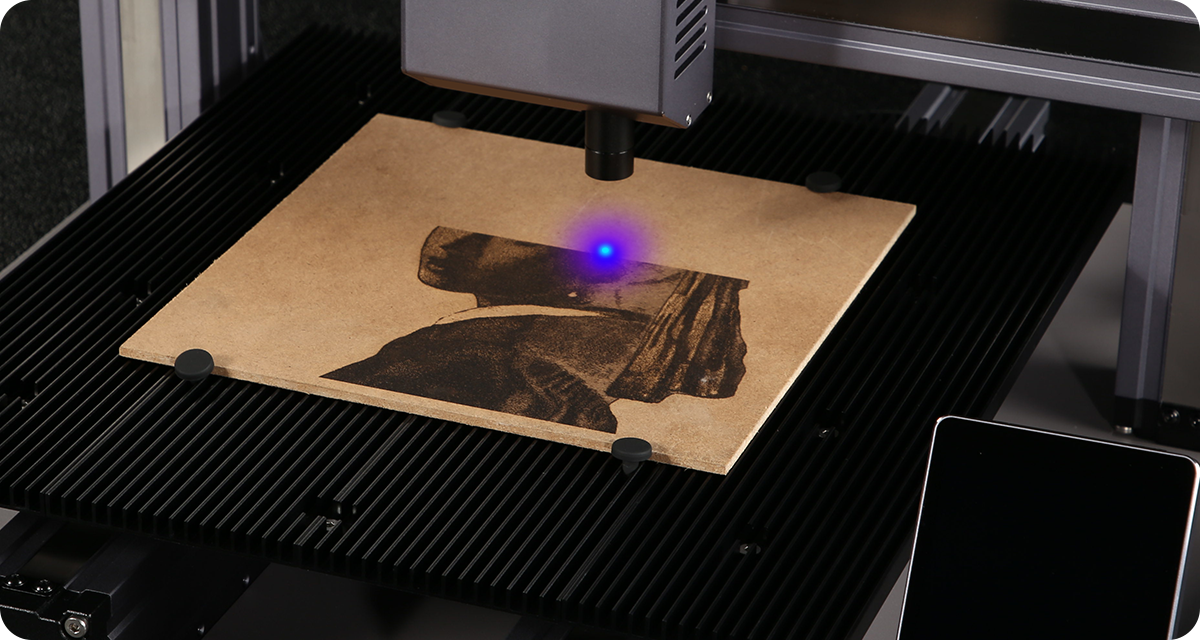

Laser engraving and cutting

The laser module allows for efficient cutting and engraving. Start creating interesting ornaments made of wood, leather, fabric and acrylic. With the 1.6 Watt laser, you can cut selected materials to bring more professionalism to your designs. The laser module is also equipped with a camera, so you can allow yourself to perfectly adjust the working area to the actual workpiece.

SnapMaker 2.0 printer laser module

The 1600 mW module allows you to engrave and cut materials such as wood, leather and plastic.

Built-in camera

The laser module has a built-in camera for Auto Focus and Camera Capture, making it easier to align the laser beam and achieve optimal engraving results.

Auto Focus

Engraving results are presented without the need to repeatedly test the focal point. The optimum parameters are selected automatically.

Camera image capture

The camera automatically takes a picture of the material placed on the workbench and sends the image to Luban's SnapMaker software where you can apply and edit designs, giving you an accurate preview of how the final result will look.

Acrylic casing

The housing is made of material that protects against the harmful effects of the laser on your eyes. In addition, the set includes protective goggles OD6.

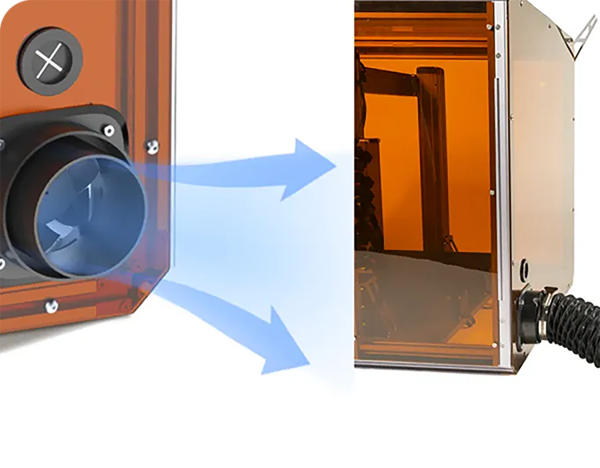

Built-in fan

The built-in fan allows to extract the fumes generated during the laser engraving process.

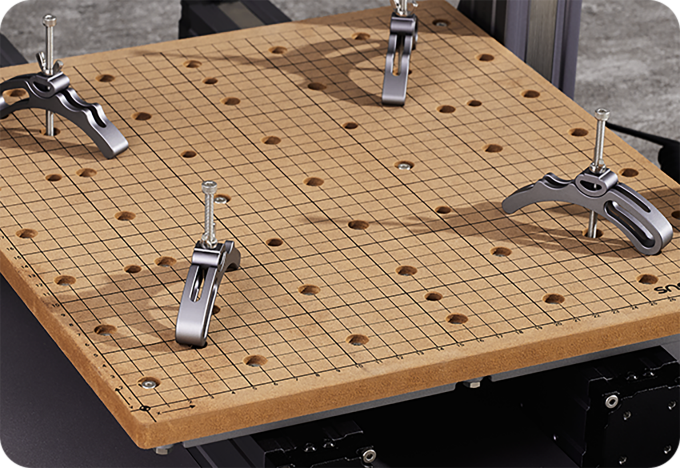

CNC module in operation.

CNC machining with Snapmaker 2.0

The CNC module allows for precision machining of materials such as wood, acrylic, carbon fiber sheets or even PCB laminate. Start making your own PCBs and put your devices in wood-milled housings, instead of looking for barriers look for opportunities, there are plenty of them! To make working with the CNC safe the set includes a wooden table and a set of hooks that prevent the material from moving.

CNC Sculpting

The new CNC unit uses ER11 collets with better concentricity for more precise and consistent results. The collets are interchangeable with other sizes. The module is compatible with drill bits with diameters from 0,5 to 6,35 mm.

Working speed of the CNC module

The spindle can operate from 6000 to 12000 revolutions per minute as required.

CNC working platform

The carving platform made of MDF provides stability and accuracy while working.

Reduction of noise while working

The enclosed housing allows to reduce the noise generated during operation by up to 10 dBA.

High quality not only on paper.

Thanks to the stable combination of steel, aluminium and perfectly matched parts the machine repeatability is as high as 0,005 mm, which is a very good result. Snapmaker 2.0 will prove to you that making a short series of devices is trivial and working with it is a pleasure.

The device is built with modules that make it easy to expand.

Snapmaker 2.0 modular design

Imagine that one construction can replace several tools in the workshop. That is exactly what Snapmaker 2.0 is! Thanks to its modular construction you can fully adjust the functionality to your individual needs. This is not a series of machines, Snapmaker 2.0 is a powerful tool for creative people like you.

3-in-1 Software

Are you surprised by the capabilities of Snapmaker 2.0? If so, you should know that the full-featured software also allows you to control all of Snapmaker 2.0's functions! No longer do you have to look for separate software for your 3D printer, laser ro uter and CNC milling machine, everything is in one place.

Software demonstration to control the device.

Wi-Fi connectivity and touch screen

For maximum convenience in setting up Snapmaker 2.0, Wi-Fi communication has been introduced. In addition to uploading files to the device, you can also update them easily, on devices on your local network you can also view the progress of your work. The touch screen is equipped with Android and an advanced processor so you can control your tools easier than ever before!

Extremely easy to assemble!

Snapmaker 2.0 is a very simple device to assemble, the motors are built into the profiles and the plates to connect the components are permanently attached to the linear systems, this solution gives you great convenience and safety. Unlike amateur counterparts, which we have to assemble for hours, Snapmaker 2.0 will take only a moment.

The assembly process is very short.

Numerous facilitations while using the device

The device is equipped with software and hardware routines that certainly make it easier to use. Auto-leveling of the work table eliminates the problem of individual platform calibration every few prints. Restoring work after a loss of voltage gives a great comfort, we do not have to be afraid that during the accidental disconnection of the device from the power supply we will lose our work. Improved in relation to the previous version of the device print cooling allows us to create elements that will be partially in the air without supports. Flexible adhesive pad makes the printout stick to the table without any additional preparations. We also do not have to use tools to unstick the printout from the platform, just bend it and the printout will fall off. The camera built in the laser module helps to determine the area on which the laser works, no more self-centering on the element with an unusual shape. Linear modules have been fully encapsulated, so we avoid the possibility of blurring the moving parts by getting chips or dust.

Are you afraid that you will not be able to handle the device? Then you are wrong! The manufacturer provides a manual that explains step by step how to assemble the device and how to configure it for specific functions, this is a huge asset.

Increased safety and work culture with the A350T chamber

The chamber created by Snapmaker is made of aluminum and acrylic that filters the laser light. It was created to increase the safety of working with the device. It has a special sensor, which immediately stops the device when the chamber door is opened. Acrylic, from which the casing walls are made, additionally protects our eyesight by filtering harmful light generated by the laser. Inside the chamber, there is an additional illumination system and ventilation system with a special hole allowing you to get rid of the unpleasant fumes generated by the device. The chamber is also perfect for 3D printing, minimizing the likelihood of damage to the model caused by the blast of air and shrinkage and warping of prints. The chamber will also reduce the amount of pollen released into the air during milling with the CNC module.

Kit includes:

- Linear modules

- Laser module (1600 mW with built-in camera)

- Module for 3D printing

- CNC module

- Controller (based on Cortex-M4 processor)

- 5" intelligent touch screen (operated by Android system, based on Quad Core A7 1.1GHz processor)

- Power supply with power cables

- Magnetic table for 3D printing with pad for increased adhesion

- Aluminium table for laser module

- Wooden table for working with CNC module (module equipped with ER-11 holder)

- Machine base with anti-slip feet

- Base for working platform

- Supports for linear modules

- Mounting for touch screen

- Cable set for connection of the modules, work table, linear modules and screen

- Converters for cables

- Fiber holder

- Flash drive

- Material mounts for working with CNC module

- Set of tools (screwdriver with interchangeable tips, wrenches, pliers, tweezers, spatula)

- Set of screws

- Plates for leveling the working platform

- Assembly and use instruction manual

- Two pairs of protective goggles (for work with CNC and laser)

- Two cutters

- Spool of filament (1 kg of PLA)

- Set of test materials

- Material for cleaning

- Protective chamber compatible with Snapmaker A350T

Snapmaker 2.0 Specifications

| Basic information | |

|---|---|

| Working area for 3D printing: | 320 (L) x 330 (W) x 350 (H) mm |

| Working area for laser: | 320 (L) x 330 (W) mm |

| Working area for CNC: | 320 (L) x 330 (W) x 275 (H) mm |

| Color display: | 5" touch screen |

| Communication: | USB drive, USB cable, Wi-Fi |

| Supported systems: | Mac OS, Windows |

| Supply voltage: | 100 V to 240 V AC |

| Frame material: | aluminum alloy, steel |

| Dimensions of assembled device: | 700 (L) x 660 (W) x 580 (H) mm |

| 3D Printing | |

| Maximum print nozzle temperature: | 275°C |

| Maximum work platform temperature: | 80°C |

| Nozzle diameter: | 0.4 mm |

| Layer resolution: | 50-300 microns |

| Supported materials: | PLA, ABS, PETG, TPU, PP, WoodFill, LayBrick |

| Filament diameter: | 1.75 mm |

| Supported file formats in Snapmaker Luban: | .stl, .obj |

| Laser engraving | |

| Laser power: | 1600 mW |

| Safety class: | 3B |

| Supported materials: | Wood, leather, plastic, fabric, paper, acrylic |

| Supported file formats in Snapmaker Luban: | .svg, .png, .jpg, .jpeg, .bmp, .dxf |

| CNC Sculpting | |

| Chuck diameter: | 0.5 mm to 6.35 mm |

| Spindle speed: | 6000 - 12000 RPM |

| Supported materials: | Wood, acrylic, PCB, carbon fiber sheets |

| Supported file formats in Snapmaker Luban: | .svg, .png, .jpg, .jpeg, .bmp, .dxf, .step, .dwg |

A real creative combo for every DIYer!

Creating prototypes of electronic devices is not only about designing schematic diagrams, drawing PCBs and assembling electronic components, but it also includes creating subassemblies such as housings and movable mechanical elements. Although we can often get many of these elements on sale, if we make a construction of non-standard shapes especially for our project, then it is worth reaching for more advanced technical solutions. One of such solutions is Snapmaker 2.0 A350T - 3D printer, laser engraver and CNC milling machine in one - a real creative powerhouse for every DIY enthusiast!

What kind of items can you produce with Snapmaker 2.0 A350T?

Snapmaker 2.0 A350T workstation enables you to make various elements of even the most non-standard shapes. With its help you can e.g. milled elements of the power transmission to the model locomotive, gears, brackets and other elements of the mechanical connections movable and fixed. In addition, by connecting the laser attachment, you can engrave various patterns and drawings in materials such as wood and plastics, creating interesting packaging and decorations.