- New

Product description: Creality AFU - resin feeder for Creality HALOT-X1 3D printer

The Creality AFU (Auto Feed Unit) system eliminates the need for manual resin replenishment by automating the entire material feeding and recovery process. Thanks to intelligent sensors and RFID technology, the unit automatically identifies the resin type, adjusts operating parameters, and informs the user about the remaining material . An integrated heating module maintains the resin at an optimal temperature , resulting in better print quality. Its compact design and seamless plug-and-play integration with the HALOT-X1 series make the AFU an indispensable tool in any 3D printing workshop.

The system continuously supplies resin during printing and automatically recovers excess resin after printing.

Main features of AFU

- Automatic resin feeding and recovery : ensures continuous operation and reduces material waste

- Built-in heating module : maintains resin temperature from 30°C to 45°C

- RFID technology : automatic resin type recognition (compatible types only)

- Laser resin level sensor : precise low tank level detection

- Real-time resin level preview : information directly on the HALOT-X1 screen

- Resin recovery function : automatic return of unused material to the bottle

- Plug and play : easy installation without additional configuration

- Compact design : perfect integration with the HALOT-X1 series

Automation and RFID - intelligent resin handling

With fully automated resin feeding, the Creality AFU monitors the resin tank level and automatically refills it whenever needed. Intelligent laser sensors and a built-in RFID module ensure accuracy and eliminate the risk of setup errors. The AFU automatically recognizes compatible resin types and communicates with the printer to adjust operating parameters. This is ideal for long print sessions and users who demand maximum convenience. This allows you to focus on designing instead of monitoring resin levels.

Temperature control, monitoring and performance

The integrated resin heating system maintains the resin temperature at 36°C , ensuring optimal viscosity and improved material flow. Resin remaining information is displayed in real time on the HALOT-X1 screen , simplifying print planning and preventing interruptions. The AFU not only automatically dispenses resin but also recovers excess resin after the process is complete . The entire process is managed through an intuitive interface at the printer, maximizing efficiency and simplifying workflow.

Creality AFU Resin Feeder Technical Specifications

- Compatibility: HALOT-X1 series 3D printers

- RFID technology: yes, for resin identification

- Heating temperature range: 30°C to 45°C

- Sensors: temperature, level, weight, RFID

- Supported resins: up to 1000 mPa s viscosity

- Automatic feeding: yes, when the level drops

- Stop: When the maximum level is reached

- Interface: HALOT-X1 touchscreen

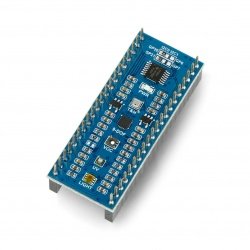

Contents of the set

- AFU Unit

- Detection module

- Detection module holder

- Tube

- Bottle adapters

- Silicone seal

- Mounting screws

- Flat screwdriver

- Connection cable

Useful links |