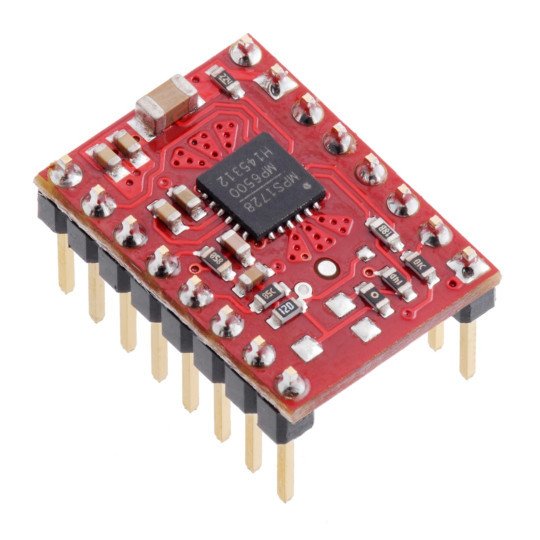

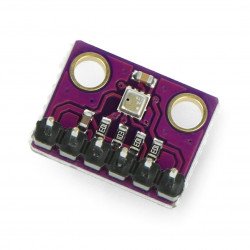

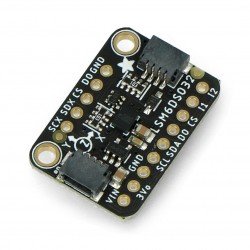

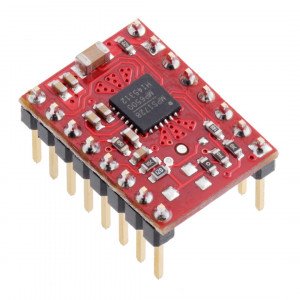

Product description: MP6500 - 35V/2A stepper motor driver - with digital current control - assembled - Pololu 2969

The chip allows you to control a stepper motor using a device capable of generating logic states such as Arduino, STM32Discovoery, Raspberry Pi or any microcontroller. Pololu module is characterized by very simple operation. In order to rotate the motor by one step, the STEP pin should be given a high state (logical one), the next sequence of zero and one will move the motor by another step, etc. The selection of the direction is performed by giving the appropriate state to the DIR pin (e.g. low state - clockwise rotation, high state - anticlockwise rotation). The driver also has the ability to select the resolution of motor operation.

Technical specification of the driver

- Supply voltage of the motor: from 4.5 V to 35 V

- Current: max. 1.8 A per coil (with cooling up to 2 A)

- Supply voltage of logic part: from 3.3 V to 5 V

- Simple control interface

- Operation in 4 different modes: full step, 1/2, 1/4 and 1/8

- Digital current regulation

- Protection against overheating of the circuit

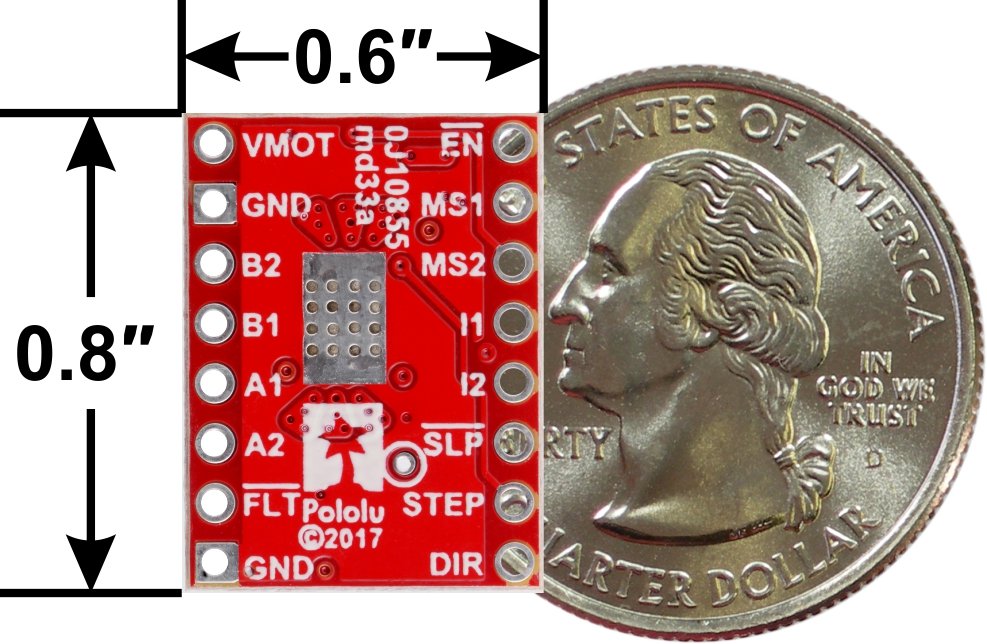

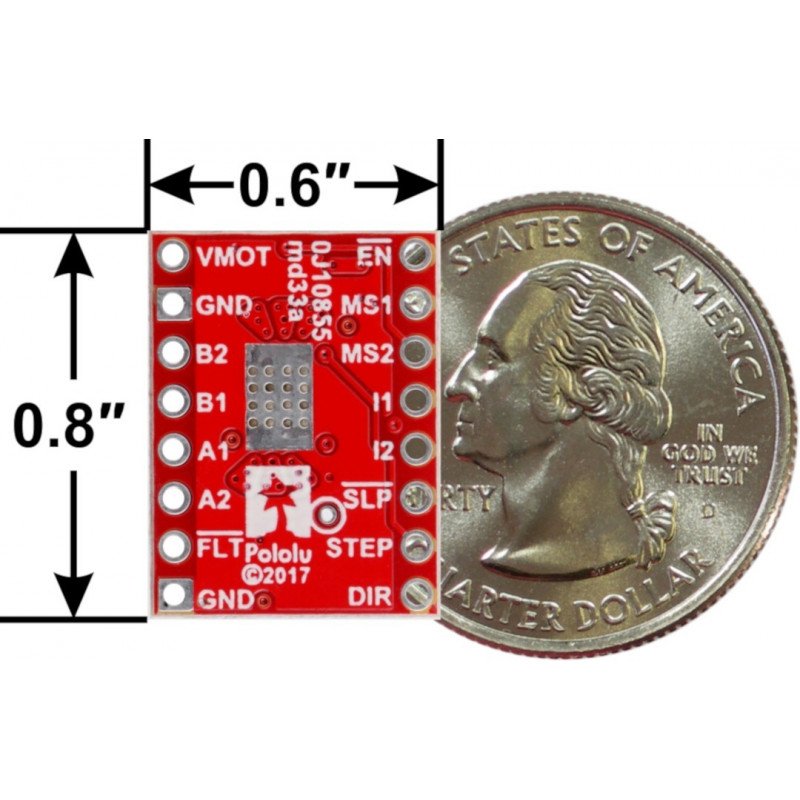

- Module dimensions: 20 x 15 mm

|

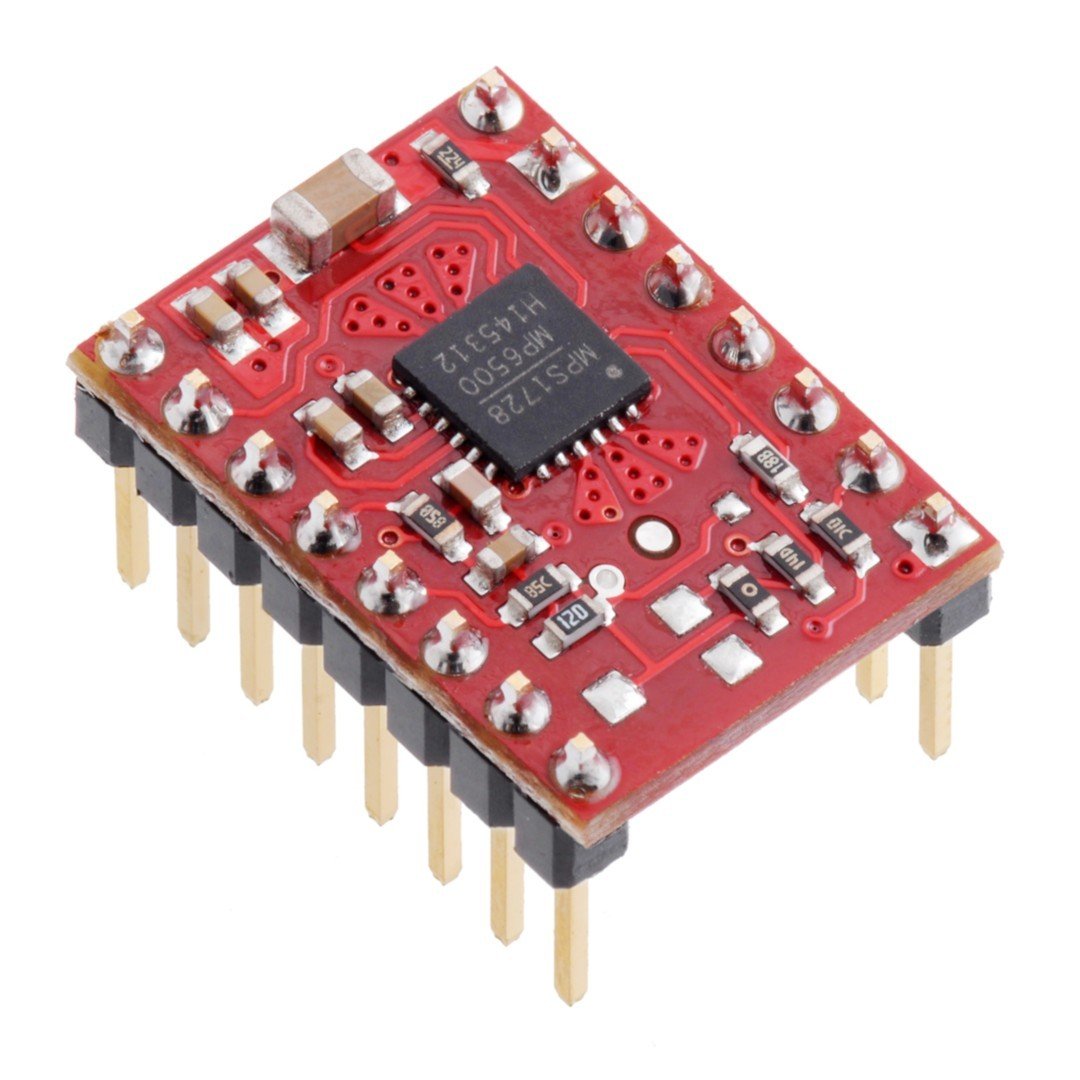

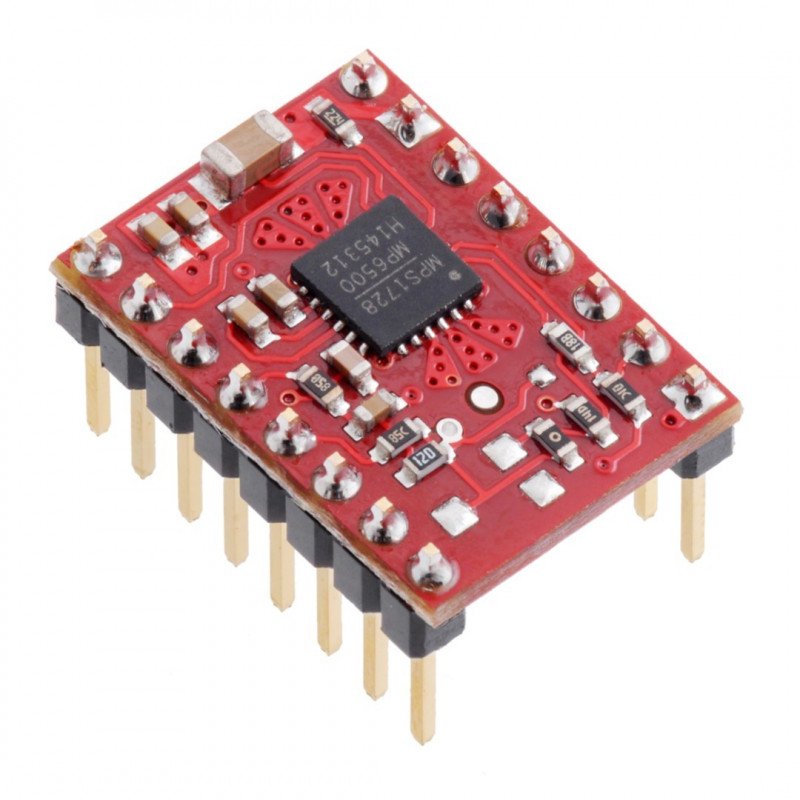

The module has soldered goldpin connectors. We also offer a version without connectors. |

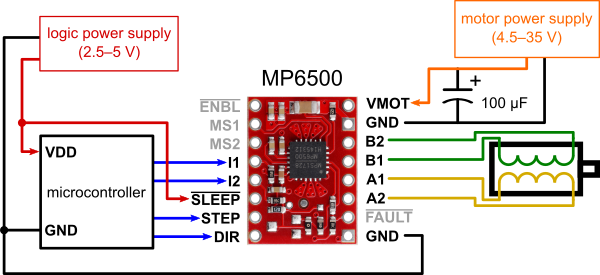

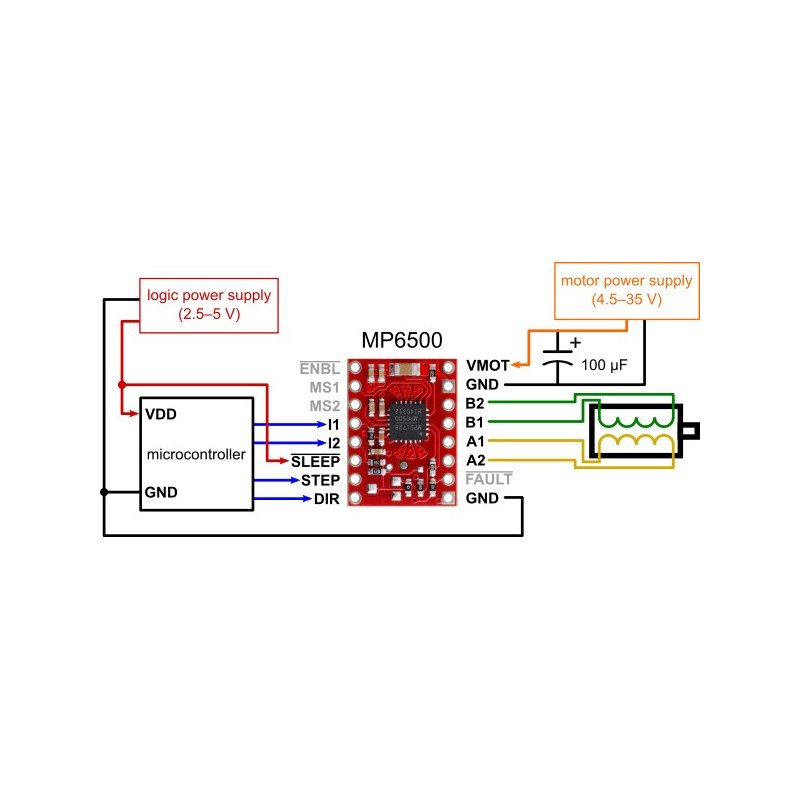

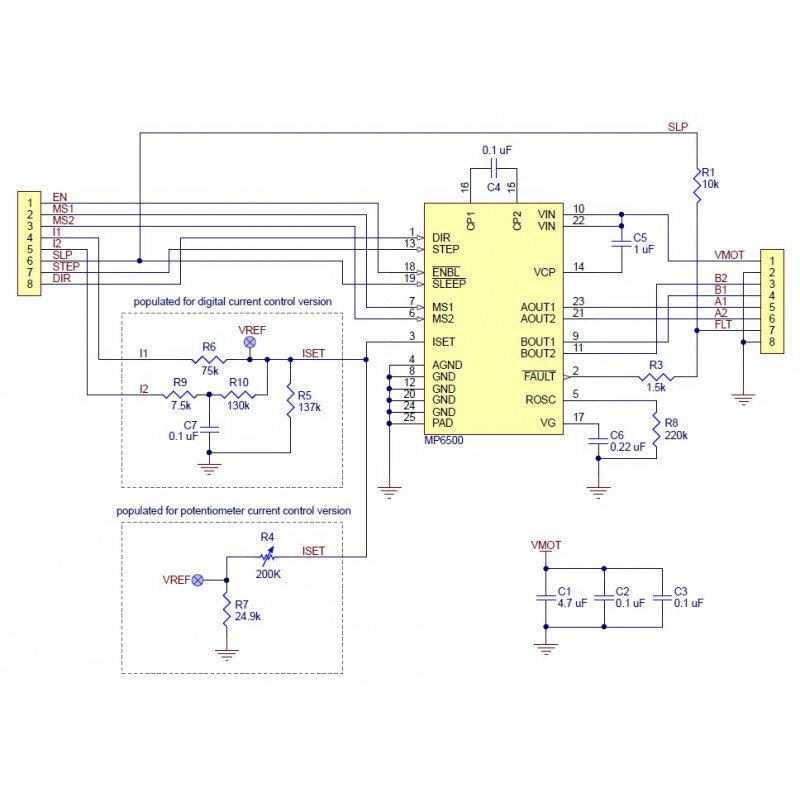

Controller connection

To control a bipolar stepper motor, connect the system according to the drawing below. In case of controlling a unipolar motor, refer to the manual. If the nominal motor voltage is lower than required driver supply (4.5V), set the current limit digitally.

The figure shows the minimum connection of the controller. A resistor of +/- 100 µF should be placed between the motor power supply pin and ground.

Power supply of the module

For supplying the logic part of the module a voltage in the range of 2.5 V to 5 V is required, which should be connected to the Sleeppin.The motor supply voltage from 4.5 V to 35 V is applied to the VMOTpin. The circuit can be used to control motors with a nominal voltage lower than the required 4.5 V. For this purpose, the maximum current consumption must be limited so as not to exceed the allowable motor current. For example, for a motor with a resistance of 5 Ω per coil and a current consumption of 1 A, the nominal supply voltage is 5 V. When supplied with 12 V, the current should be limited so that it does not exceed 1 A.

|

Caution! Connecting and disconnecting the motor while the controller is on can damage the system. |

Resolution and step size

The step size is selected using MS1, MS2 inputs. The possible settings are shown in the table below. The MS1 and MS2 inputs have an internal pull-down resistor (500 kΩ).

| MS1 | MS2 | Resolution |

| low | low | Full step |

| high | low | 1/2 step |

| low | high | 1/4 step |

| high | high | 1/8 step |

Other inputs

One pulse on the STEP pin causes one step of the motor in the direction selected by giving the corresponding logic state to the DIR pin. If the motor is to spin in one direction only, the DIR pin can be left disconnected.

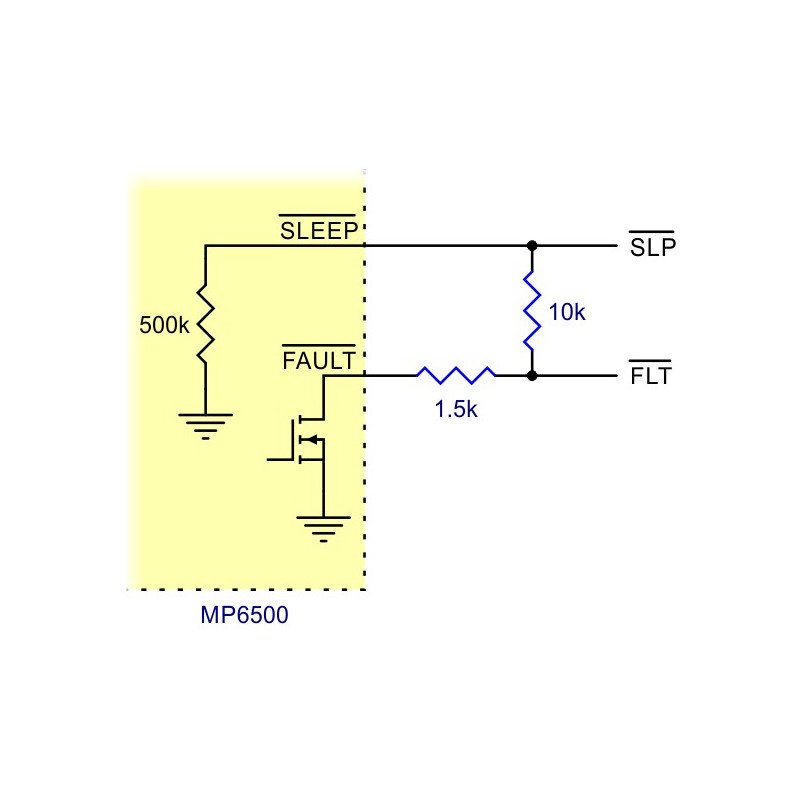

The chip has two different inputs to control the power supply: SLEEP and ENBL their description can be found in the documentation. Note that the controller pulls both of these pins through internal 500 kΩ pull-down resistors. The default SLEEP state prevents the motor from running, a high state must be applied to it (it can be connected directly to a 2.5 to 5 V logic supply or it can be controlled by connecting to a digital MCU output). The default state of ENBL is controller on, it can be disconnected.

The FAULT output turns off when the F and H bridges are disabled due to current protection, overvoltage protection, thermal shutdown, or voltage dropout protection. It connects to the SLEEP pin via a 10 kΩ resistor, which functions similarly to FAULT. When SLEEP has a high state, it is not necessary to connect FAULT.

|

Note! As a result of connecting SLEEP and FAULT and when a fault occurs, the voltage on the SLEEP pin can drop below 2.1 V if it is not amplified enough. It is recommended to use resistor min. 4.7 kΩ with this pin or connect SLEEP directly to VCC. |

Current Limitation

To achieve high speeds, the motor supply usually needs to be higher than it would be without current limiting. For example, a stepper motor may have a maximum current rating of 1 A with a coil resistance of 5 Ω, which would indicate a maximum motor supply of 5 V. Using this motor with 9 V would allow higher speeds, but the current must be limited to less than 1 A to prevent damage to the motor.

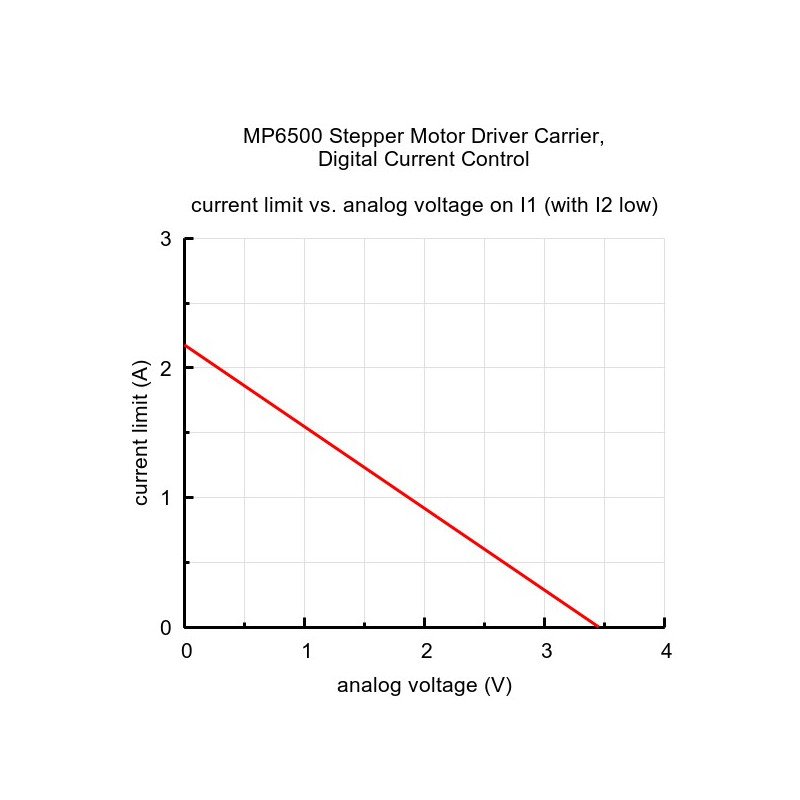

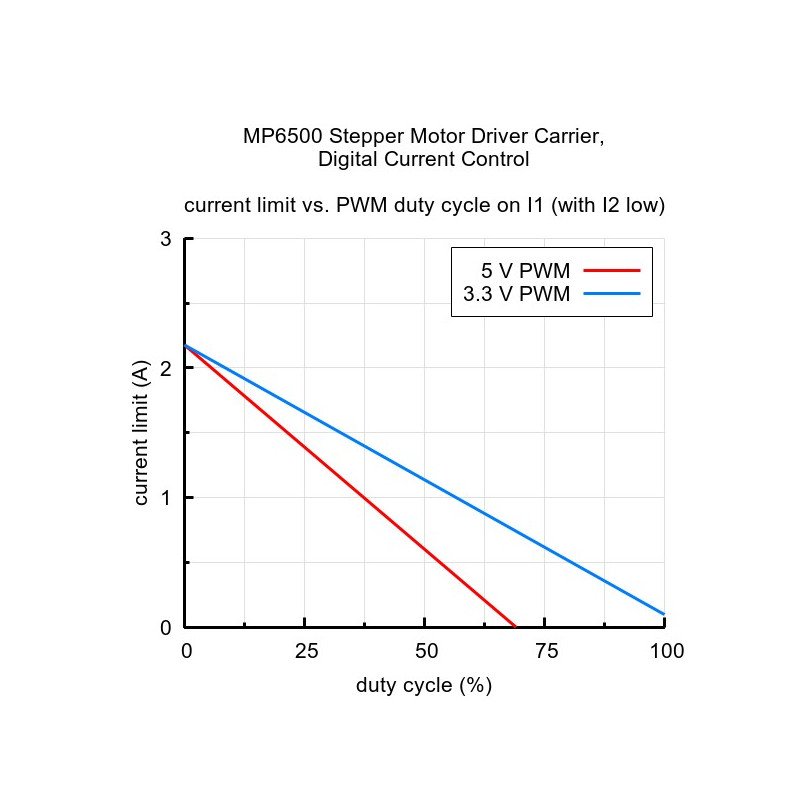

The controller uses the I1 and I2 outputs to set the current limit. If both I1 and I2 are disconnected, the current limit defaults to 0.5 A.

| I1 | I2 | Current limit |

| Z | Z | 0,5 A |

| low | Z | 1 A |

| Z | low | 1,5 A |

| low | low | 2 A |

Heat dissipation

The board is designed to dissipate heat at a current consumption of about 1,8 A per coil. If the current will be much higher, you should use an external heat sink for which you can use thermally conductive glue.

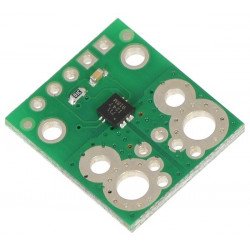

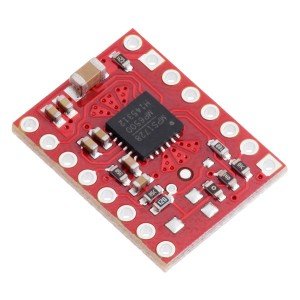

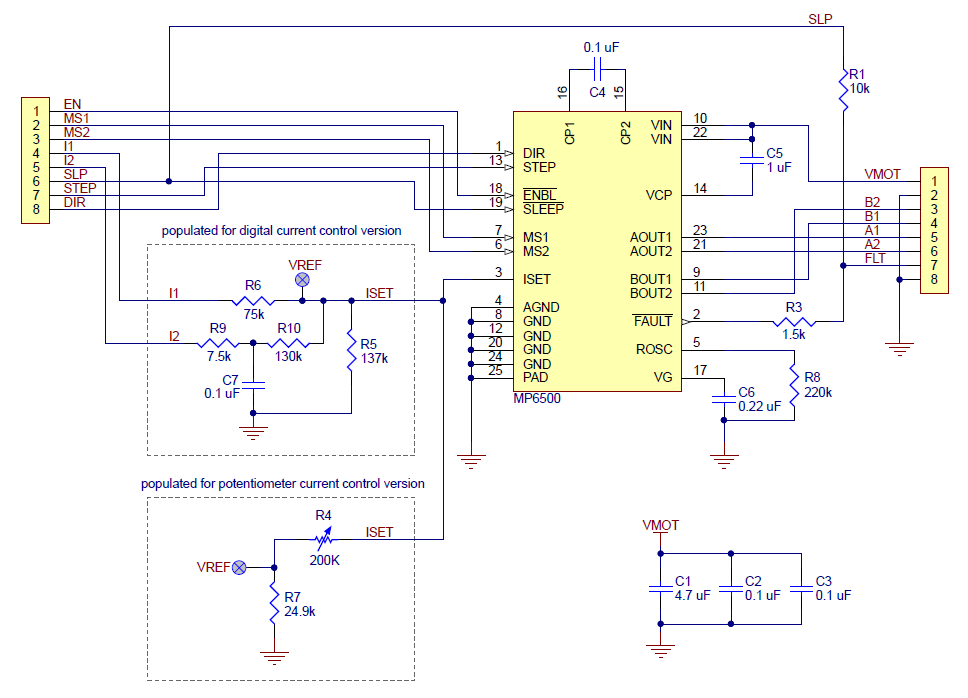

Circuit diagram

The circuit contains the necessary passive components for proper operation of the controller. Circuit diagram is shown in the figure below.

Useful links |