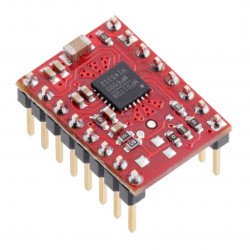

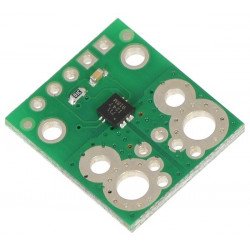

Product description: G2 High-Power 24v21 - 40V/21A single channel motor controller - Polol 2995.

The module allows to control one DC motor. The motor can be supplied with voltages from 6.5 to 40 volts with a continuous current consumption of up to 21 A, temporary (for 10 ms) to 100 A. Speed can be controlled by PWM signal, direction by digital DIR output - giving low (logical 0) or high (logical 1) state. The device also has a current flow sensor and the possibility to limit the motor current.

Specification

- Number of channels: 1

- Motor supply voltage: 6.5 V to 40 V

- Supply voltage of the logical part: 1.8 V to 5.5 V

- The outputs operate at 5 V

- Continuous current: up to 21 A

- Temporary currents: up to 100 mA (for several ms)

- PWM signal frequency: 100 kHz

- Current sensor sensitivity: 0.02 V/A

- Security:

- against reverse connection of the supply voltage

- against too low a supply voltage

- before a short circuit

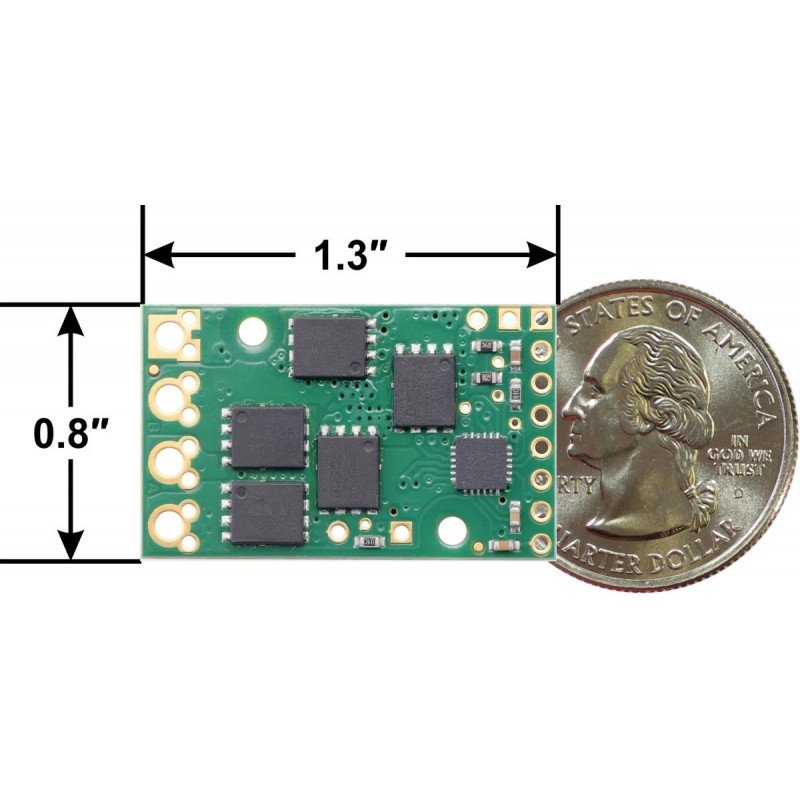

- Dimensions: 33 x 20 mm

- Weight: 5,0 g

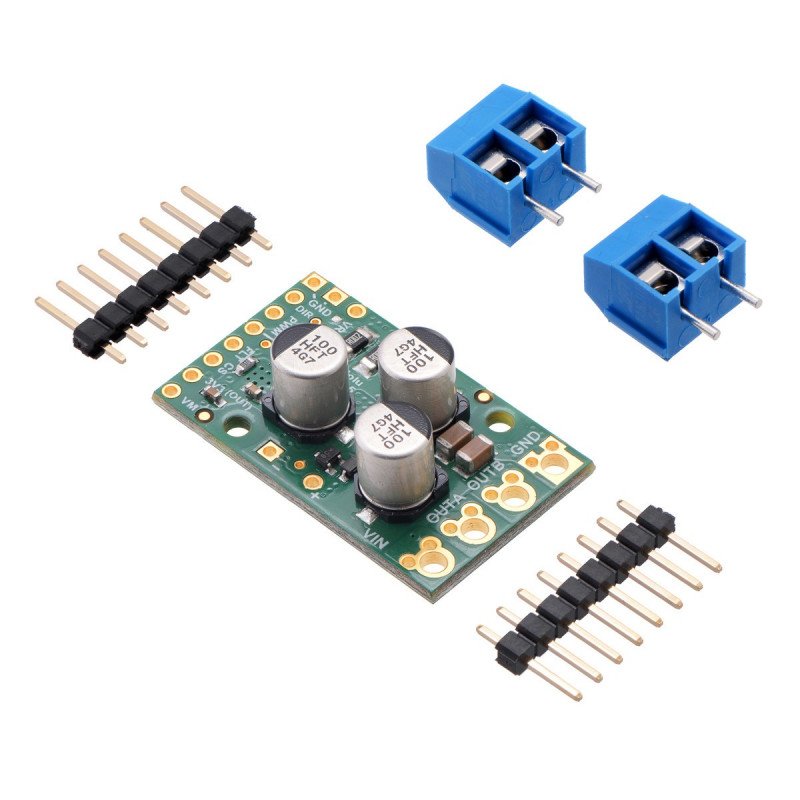

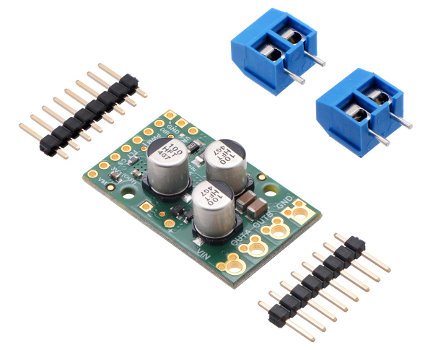

- Modules, goldpin and screw connections included

|

When using a fully charged battery, the real voltage can be significantly higher than the nominal voltage. Therefore, the manufacturer recommends the use of batteries with a nominal output voltage up to 28 V. |

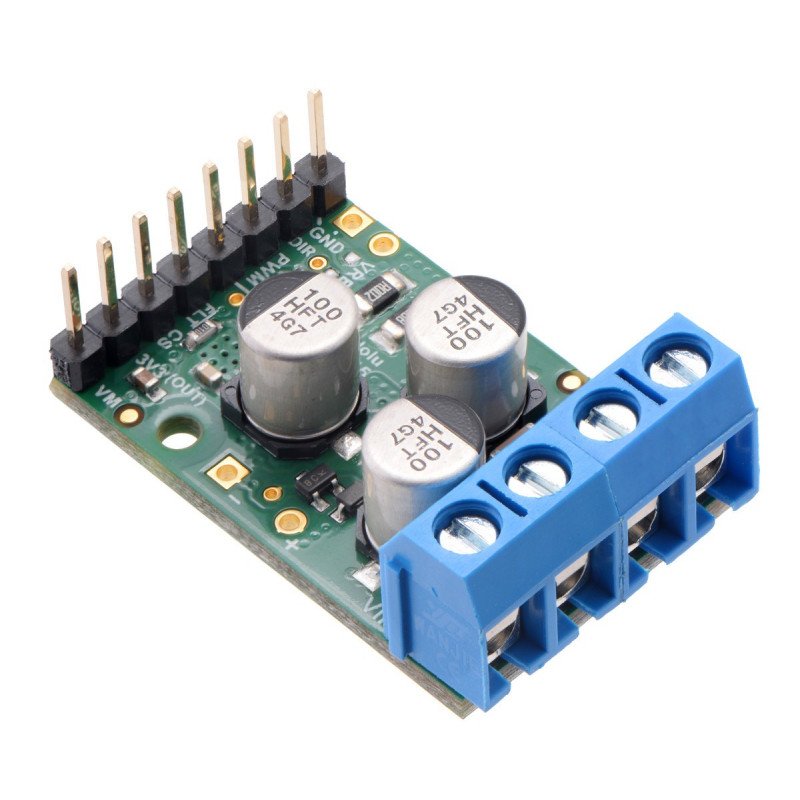

The set includes a controller and connectors for self-soldering.

The set includes a controller and connectors for self-soldering.

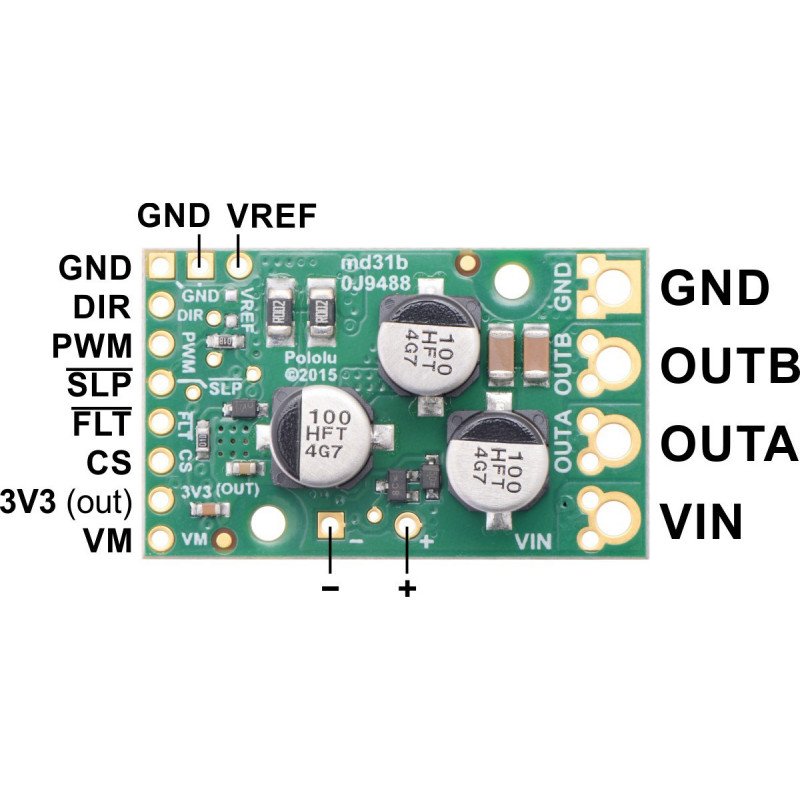

Connection

For proper operation of the module, it is necessary to supply power to the motors between the VIN and GND pins and connect the outputs responsible for motor movement, which are described in the table below.

| PIN | Description |

|---|---|

| VIN | Motor supply voltage from 6.5 V to 40 V |

| VM | Power output after reverse connection protection. |

| +/- | Soldering out to solder an additional capacitor on the motor supply lines. |

| 3V3 (OUT) | Output voltage from the regulator 3.3 V, with a current capacity of several mA. Can be used as a reference voltage for other systems. Special care must be taken not to short circuit the adjacent pins. |

| GND | System weight |

|

OUTA OUTB |

Outputs for DC motor connection. |

| PWM | Speed control input for PWM signal connection. Default is in low state |

| DIR | Digital input to control the direction of motor rotation. Low state by default. |

| SLP | If a low state is given, the system is put into standby mode. By default, the output is in the high state - the system is armed. |

| FLT | An open-drain output that indicates the occurrence of a fault. The appearance of a low state indicates a system fault. |

| CS | 20 mV/A current sensor output with 50 mA offset. |

| VREF | Reference voltage input. Connect the resistor to ground to limit the maximum output current. Without additional resistor the maximum value is 50 A. |

Operating modes and current limitation

The table shows the dependencies of the outputs on the input signals:

H - high state

L - low state

X - no matter

|

PWM |

DIR |

OUTA | OUTB | Engine condition |

|---|---|---|---|---|

|

% |

H | H | L |

The motor is clockwise at % PWM. |

|

% |

L | L | H |

The motor turns counterclockwise at % PWM |

|

L |

X | L | L | Braking. |

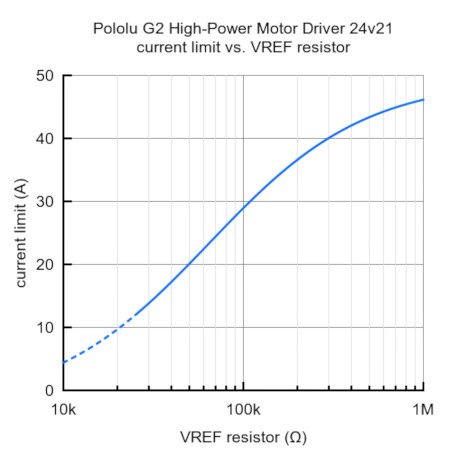

The PWM signal frequency should be up to 100 kHz, typically 20 kHz is used. The speed is proportional to the filling of the PWM signal. Additionally, the system has a VREF pin to limit the flowing current. The default value is limited to 50 A, a resistor between VREF and ground should be connected in shifts. The resistance dependence is shown in the diagram.

Motor current depending on the resistance connected between the VREF pin and ground.

Error detection conditions

The controller can detect various errors signaled by setting the FLT pin to low. In order to use it, it must be connected to a high state (system logic voltage). Short circuit on the outputs, too low voltage and overheating can be detected. All errors disable the motor outputs but do not block them, this means that the controller will try to resume operation after the error has disappeared.

The controller can handle large current surges for a short time (100 A for several milliseconds). In continuous operation it can withstand 21 A, but this depends on external conditions such as ambient temperature and motor cooling. A heat sink can be added to the plate to improve performance.

The controller has no automatic shutdown in case of overheating. Care must be taken to avoid damaging the system.

Video

Film describing the operation of the H-bridge - direct current motor controller.

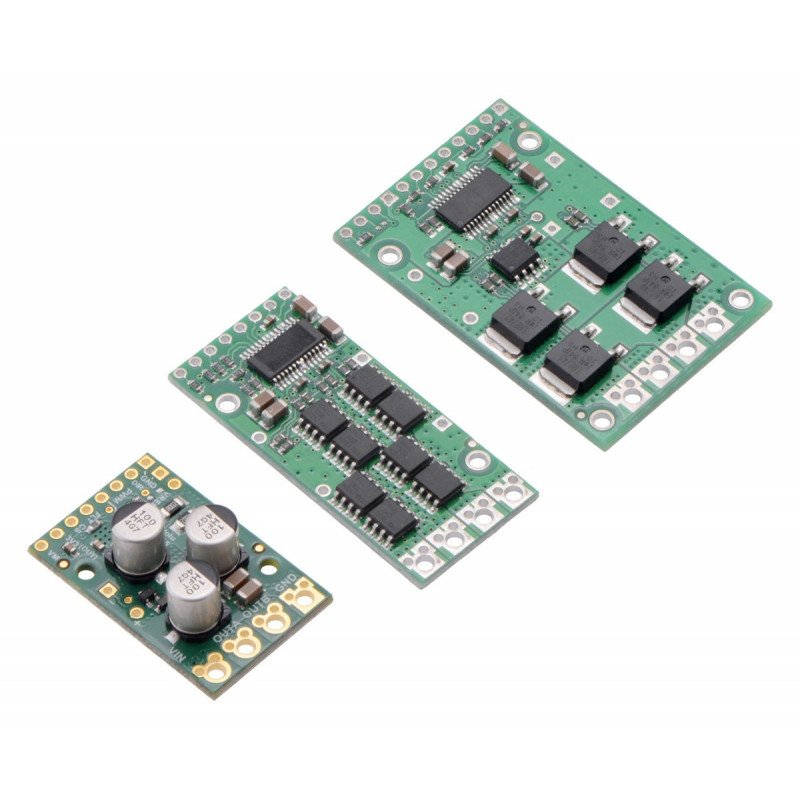

List of G2 High Power controllers

| Name |

Voltage power supplies |

The current Continuous |

|---|---|---|

| G2 High-Power 18v25 | 30 V | 25 A |

| G2 High-Power 18v17 | 30 V | 17 A |

| G2 High-Power 24v21 | 40 V | 21 A |

| G2 High-Power 24v13 | 40 V | 13 A |

Useful links |