Angle grinder is a particularly valuable acquisition for any home worker and professional. Range possible with it works is very wide and goes far beyond what one would conclude from the power tools. Angular grinding machine can be used for, except for grinding for cutting (in this role are, of course, is often), polishing and other works around the country. In this category you will find the useful disks for grinding and cutting various materials, and the implementation of the transitional and final machining.

Grinding discs

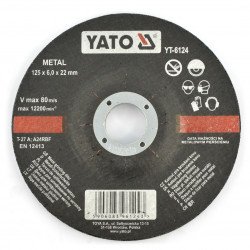

Metal grinding disc Yato YT-6124 - 125x6mm

Convex disc designed for grinding metal. The disc dimensions are 125 x 6,0 mm. Order number: YT-6124Flap disc - depressed shape YT-83292

Flap wheel is designed for working on wood and wood-like materials. The size of the wheel is 125 x 8 mm. Part No.: YT-83292.Metal grinding disc Yato YT-5947

Convex wheel designed for grinding stainless steel. The disc measures 125 x 6,8 mm. Part No.: YT-5947.- Reduced price

- SPECIAL OFFERS

Metal cutting disc Yato YT-5924

The blade is designed for cutting metal. The dimensions of the blade are 125 x 2,5 mm. Part No.: YT-5924.Stainless steel cutting disc Yato YT-6104

The blade is designed for cutting stainless steel. Dimensions of this blade are 125 x 2,5 mm. Order number: YT-6104.Flap disc - depressed shape YT-83294

Flap wheel is designed for work on wood, metals and some plastics. Dimensions of the wheel are 125 x 8 mm. Part No.: YT-83294.Rules of work with the grinder corner

The basic principle, the key, however, for almost all of the work performed by the machine is the right choice of speed of rotation of the disk and its type. Solid materials must be reduced at the fastest possible speeds – this applies, for example, steel (including stainless), aluminum and other metals. Their finishes are great sandpaper of different thicknesses. For wood and most plastics should be used, however, it is other instruments because of the low temperature processed material can withstand without darkening (in the case of wood) or melting (in the case of plastic). For wood processing it is necessary to use toothed discs (metal, reminding a bit of the drives for chainsaws, carpentry), and for plastics – special diamond disks.

Discs for cutting and grinding metal – why is this not enough of one?

Wheels, designed for processing metals are distinguished primarily by thickness. Models are available with a thickness from about 1 mm to several millimeters. The difference occurs in the application, which is the shield. Thin discs, i.e. models up to about 3 mm, is used for cutting profiles, pipes or metal plates (such as steel). However, the grinding of metal often requires a pressure in a direction parallel to the axis of the disk – thin shield would be subjected to in this case, unwanted deformation (not to mention the risk of damage), hence, for this type of work used wheels is much thicker – even good. 6 mm. On each disc you'll find the labeling of processed materials and works with them to perform – always make sure that based on the spindle, the shield will be suitable for the material to be processed.

Drives for grinding machines the store Botland

In our offer we are the most useful in daily work design, quality discs from a reputable manufacturer of tools firms Yato. You will find here as wheels for cutting metal (e.g., YT-6104 for grinders 125 mm), grinding (including a special version to work with was a steel – YT-5947) and universal blade (e.g., YT-83292 for working with wood or YT-83294, which will also cope with plastics and metals). If you are the owner of a large meat grinder, which supports the discs with a diameter of 230 mm, of course, You will be pleased to hear that you will also find here grinding wheels and cutting wheels for Your instrument.