Postprocessing and filament merging systems

Device for washing and curing prints - Anycubic Wash & Cure 3 Plus

A device from Anycubic designed for washing and drying models made of photosensitive resin. It offers a large working area , so it can wash and harden large prints or...Creality Resin Tool Kit for 3D printer

A set of tools necessary to work with resin 3D printers. The package includes a plastic spatula, brush, funnel made of stainless steel, silicone funnel, PVC gloves and a...Nebulizer for Polysher - 2pcs - Polymaker PM70801

Two replacement nebulizers for the Polymaker Polysher . The nebulizer is responsible for transforming liquid isopropyl alcohol (IPA) into a fine mist and atomizing it in...- Reduced price

- SPECIAL OFFERS

Smoothing device - Polymaker PM70524

A small, intelligent device used to smooth the surface of the finished print, made of PolySmooth filament by Polymaker. The produced mist of isopropyl alcohol (IPA) gently...Print wash and cure station - Elegoo Mercury Plus V3.0

The Elegoo Mercury Plus V3.0 is a versatile 2-in-1 resin model washing and curing station , compatible with most LCD/DLP/SLA 3D printers. With increased capacity, two...Print washing and curing machine set - Elegoo Mercury XS Bundle

The Elegoo Mercury XS Bundle is a 3D resin model cleaning and curing kit consisting of two independent stations . It offers a large 7000ml cleaning volume, 360° UV curing,...Original Prusa Curing and Washing Machine CW1S

Original Prusa CW1S is a device recommended for Prusa SL1S 3D printer , but it is also compatible with other SLA printers available on the market. CW1S is a multifunctional...Print drying and curing device - Sunlu RC-2

Advanced device for processing 3D models from resin. Thanks to its spacious chamber , it allows for simultaneous curing of larger models or several smaller ones. Equipped with...Sunlu Filament Connector FC01 - filament connection system

Sunlu Filament Connector FC01 is a device designed for 3D creators who want to minimize filament waste and save on consumables. With this easy-to-use bonding technology, you...Print washing and drying device - Anycubic Wash Cure 3

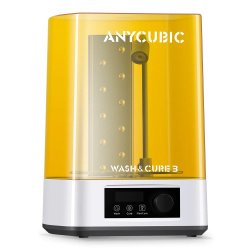

A device from Anycubic designed for washing and drying models made of photosensitive resin. The top cover provides effective protection against UV radiation, and the...See also

3D print post-processing - the most important information

To achieve perfect quality of 3D prints, sometimes they need additional processing. For this purpose, special equipment using various technologies to improve the appearance of 3D prints is used.

- In the case of elements made of resin, equipment working in two modes - drying and washing - works great. In addition, this type of equipment final harden the printout by uniform exposure to ultraviolet waves. An extremely practical function is the regulation of the immersion level, thanks to which you can continuously control the progress of the printout washing.

- The vapour smoothing device, on the other hand, as the name suggests, uses vapour to remove any irregularities and roughness in the print surface. The device automatically selects not only the pressure, but also the temperature and density of the vapour. In practice this means that all prints, even the most complicated ones, will be evenly smoothed.

Post-processing of 3D prints is also based on the effective removal of the so-called support structures, which were formed from the material type Z-SUPPORT.

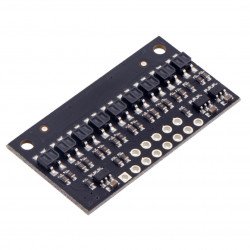

Devices for permanent bonding of filaments

In order to quickly and, above all, permanently connect the heat-shrinkable material, special systems are used, which do not cause any delays during the work of the 3D printer. Such a solution makes it possible for devices equipped with only one nozzle to print in different colors. Thanks to the equipment for combining filaments you will also create practical supports.

- We offer universal devices which work with all printers using 1,75 mm diameter filament. The proposed devices can be successfully used for the most popular types of heat-shrinkable materials.

- We also offer devices which use IPA fluid for cleaning printouts. The use of high quality materials, such as stainless steel, guarantees a long life of the equipment. Thanks to the work time counter you know exactly how long a particular printout is subjected to the cleaning process. IPA, or isopropyl alcohol, effectively removes all resin residues that are in hard to reach places. Proper precautions must be taken when working with liquids of this type.

Models are also available that allow the use of up to 8 different filaments, so that the print will gain a variety of colors. Operation of the device is easy and intuitive, so even novice users can successfully use it. Before starting a project, the equipment must be set up properly. In practice, this means that you need to select one of the loaded shrinking materials, and the device will automatically cut the filaments to a specified length.

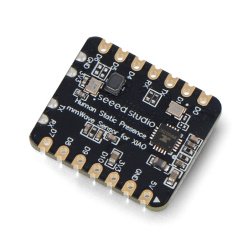

Filament blending - additional information

Also worthy of special attention are devices that allow you to permanently and solidly combine different types of filament. This functionality allows you to create complex prints characterized by high detail. In case of any questions concerning post-processing devices or combining of filaments we encourage you to contact us. Our experienced staff will be happy to dispel any doubts and help in the selection of equipment that will meet your expectations in 100%. We provide a contact form, e-mail address and telephone number.