Description: Dimafix Pen printing glue - 90 ml

A product that improvesthe adhesion of 3D printsto a hotbed glass surface. Product for use inprintersusing FFF/FDM technology. Designed to work with most types of filamentsavailableon the market. It shows adhesive properties at temperatures above 50°C. The product is in a convenient90 mlbottle. Dimafix Pen is applied by thinly spreading the adhesive coating on the glass surface of the working table with a sponge at the end of the neck of the bottle.

Dimafix Pen printing glue - 90 ml.

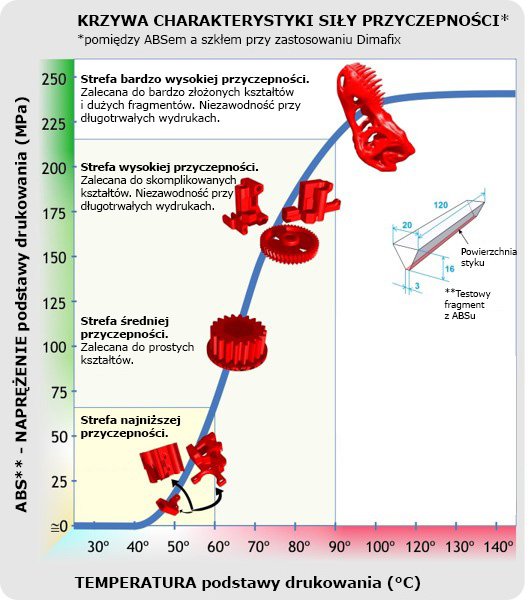

Four action zones of the preparation

The Dimafix adhesive coatingprevents unwanted tearing of the model from theprinting table, even for filaments for professional use. It is suitable for work withABS, PVA, Filaflex,Polyprylene, HIPS, among others. Adhesive properties of the product change with the temperature of the hotbed glass surface. On the example of ABS material we can distinguish four thermal ranges of Dimafix:

- Zone IV- temperaturefrom 95°C to 120°C.Maximum adhesion of the printed element, any size and shape. This range provides an improvement in printing quality of sharp edges and tops of the 3D model.

- Zone III- temperaturefrom 75°C to 95°C.Zone of high adhesion of the print. 3D model can have any shape and maximum size of 200 x 200 mm. Good print quality without curling even when print cooling is on.

- Zone II- temperaturefrom 65°C to 75°C.Average adhesion power suitable for straight components without sharp edges.

- Zone I- Temperaturebelow 65°C.For easy exit of the printout from the table. If the table cools down, the printout should exit by itself.

Graph of temperature dependence of adhesion properties (for ABS).

|

Dimafix spray with400 ml capacity is also available in our offer. |

Useful links |