How do stepper motors work?

How does a stepper motor work? A stepper motor is a brushless motor powered by impulse voltage (electric current), the shaft of which does not rotate continuously as in the case of most types of electric motors, but discreetly, where individual steps correspond to rotations by the same number of angular degrees - e.g. stepper motor with a resolution of 200 steps, which corresponds to one complete revolution of the shaft, a single step corresponds to a rotation of 1.80°.

Principle of operation of a stepper motor (construction of a stepper motor)

The stator of the stepper motor consists of grouped windings to which voltage pulses are successively supplied. A single voltage pulse supplied from the control system to the winding causes the rotor to rotate by one step. This is, in simple terms, how a stepper motor works.

Advantages of stepper motors

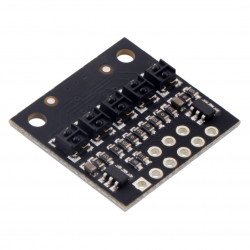

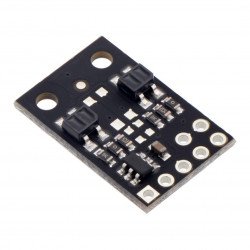

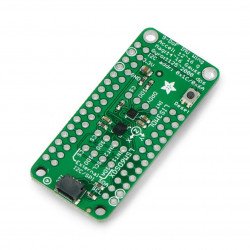

By connecting a stepper motor to Arduino via a controller (see also: stepper motor drivers), you can programmatically set the motor's operating parameters, such as rotational speed, acceleration or the angular position of the rotor.

The design of the stepper motor is relatively simple. In practice, this means reliable operation and low failure rate in stepper motors.

What factors should be taken into account when selecting a stepper motor for a project?

Choosing a stepper motor is not an easy task at all. First of all, remember to adjust all parameters (including torque and gear ratio) of stepper motors to a specific application.

The first criterion for selecting a motor is its required sequence of the most frequently performed movements in terms of number in time and angle of rotation. This is determined by the time required to reach the specified motor shaft position and the acceleration and deceleration between zero and maximum speed. Information regarding rotational speed can be found in the specific product description.

For proper and safe operation of the application, the motor must also be selected in terms of step resolution, torque, acceleration torque and shaft load.

Stepper motor projects - additional information

The geometric dimensions of the motor should also be taken into account, including the spacing of the mounting holes, however, two stepper motors with the same rated supply voltage and dimensions very similar to each other may differ in current consumption and winding design - unlike unipolar motors, bipolar motors have each winding equipped with in the center tap, which allows for increased torque. The use of stepper motors is very common, including: due to the ease of engine control.

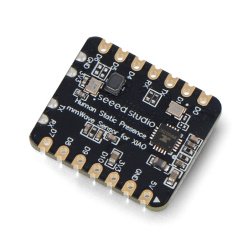

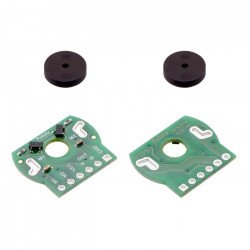

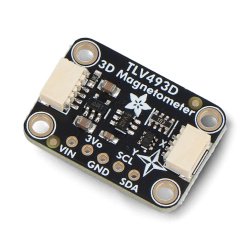

Stepper motors operating in a closed feedback loop

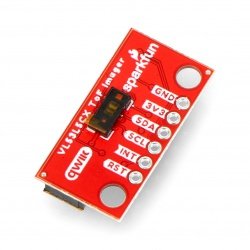

Typically, stepper motors operate in open-loop feedback systems. For applications where increased operational reliability is required, stepper motors operate in a closed feedback loop that uses a sensor that allows you to constantly track the position of the motor shaft. Stepper motor failure is usually detected using a diagnostic computer.

Stepper motors - motors with a wide range of applications

The stepper motors offered by the Botland store are available in various sizes and operating parameters, such as rated supply voltage and torque, which allows you to optimally select the motor for your device design.

Other information regarding the use of stepper motors

Since stepper motors require a pulse voltage supply, in practice this allows the stepper motor to be used in applications where accuracy is a priority.

Thanks to this, such stepper motors are successfully used in CNC machines and power tools for manual, precise material processing, as well as in hard drives, clocks, printers, two-dimensional plotters, engraving machines, laser heads, scientific research equipment, and broadly understood robots. - also those supporting the production of integrated circuits and other electronic components.

Stepper motors available in the Botland range

For applications requiring increased precision of operation, We have also prepared an offer of stepper motors with gears extending the standard step resolution of the motors. We also encourage you to check out the entire engines category, which includes, among others: DC DC motors, vibration motors and linear motors . Do you have questions about the construction of a stepper motor or don't know which stepper motor driver to choose? We encourage you to contact our experienced advisors.